Automatic bale plucker

An automatic cotton picking machine, applied in the field of textile machinery components, can solve the problems of not installing impurity removal devices, affecting cotton picking efficiency, and poor cotton uniformity, so as to improve cotton picking efficiency, ensure uniformity, and reduce impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

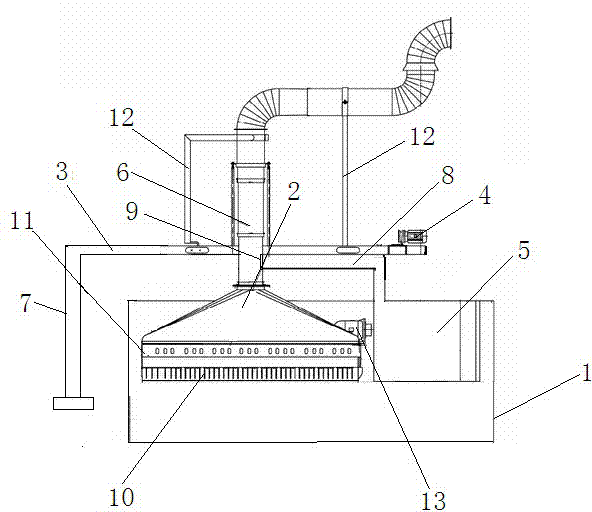

[0016] Such as figure 1 As shown, an automatic cotton grabbing machine includes a peripheral retaining ring 1, a suction bin 2, a support frame 3, a miscellaneous discharge fan 4, a miscellaneous discharge box 5 and a cotton delivery pipe 6, and the suction bin 2 is suspended on the support Just below the frame 3, and located in the peripheral retaining ring 1, one end of the support frame 3 extends vertically downwards with a fixed pile 7, the fixed pile 7 is fixed on the ground, and the bottom end of the fixed pile 7 is poured on the ground through concrete to improve The firmness of the installation is fixed. The outlet of the suction bin 2 is connected with a cotton delivery pipe 6. The suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com