High-efficiency heterogeneous catalytic iron oxide carbon micro-electrolytic filler and preparation method thereof

A technology of heterogeneous catalysis and iron-carbon oxidation, which is applied in the fields of chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of iron sludge blockage of treatment equipment, short running time, and easy hardening of fillers, etc. Problems, to achieve the effect of reducing labor intensity, reducing production costs, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

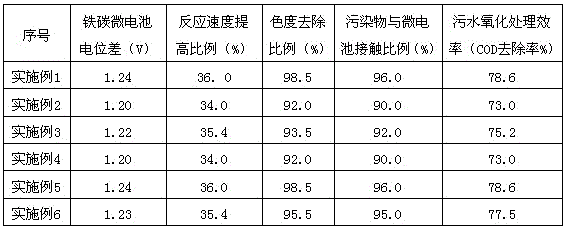

Examples

Embodiment 1

[0060] A high-efficiency heterogeneous catalytic iron oxide carbon micro-electrolytic filler is composed of the following raw materials in parts by weight:

[0061] Pure Iron Powder 55 Pig Iron Powder 18

[0062] Graphite powder 5 Activated carbon powder 10

[0063] Copper powder 5 Manganese powder 5

[0064] Aluminum powder 5 Fine wood chips 5

[0065] Sodium silicate 3.5 Sodium borate 3.5

[0066] Pyrite powder 2.5 Binder 6.5.

[0067] Wherein the pure iron powder has a purity of ≥99% and a particle size of 100 mesh, and the pig iron powder has a purity of ≥95% and a particle size of 100 mesh;

[0068] The carbon content of the graphite powder and the activated carbon powder is more than or equal to 98%, and the particle size is 100 mesh;

[0069] The purity of the copper powder is more than or equal to 90%, and the particle size is 100 mesh;

[0070] The purity of the manganese powder is more than or equal to 98%, and the particle size is 100 mesh;

[0071] The parti...

Embodiment 2

[0079] A high-efficiency heterogeneous catalytic iron oxide carbon micro-electrolytic filler is composed of the following raw materials in parts by weight:

[0080] Pure Iron Powder 45 Pig Iron Powder 25

[0081] Graphite powder 8 Activated carbon powder 5

[0082] Copper powder 2 Manganese powder 10

[0083] Aluminum powder 2 Fine wood chips 10

[0084] Sodium silicate 1 Sodium borate 6

[0085] pyrite powder 2 binder 5;

[0086] Wherein the pure iron powder has a purity of ≥99% and a particle size of 100 mesh, and the pig iron powder has a purity of ≥95% and a particle size of 100 mesh;

[0087] The carbon content of the graphite powder and activated carbon powder is more than or equal to 98%, and the particle size is 100 mesh;

[0088] The purity of the copper powder is more than or equal to 90%, and the particle size is 100 mesh;

[0089] The purity of the manganese powder is more than or equal to 98%, and the particle size is 100 mesh;

[0090] The particle diamete...

Embodiment 3

[0098] A high-efficiency heterogeneous catalytic iron oxide carbon micro-electrolytic filler is composed of the following raw materials in parts by weight:

[0099] Pure Iron Powder 65 Pig Iron Powder 10

[0100] Graphite powder 2 Activated carbon powder 15

[0101] Copper powder 10 Manganese powder 2

[0102] Aluminum powder 10 Fine wood chips 2

[0103] Sodium silicate 6 Sodium borate 1

[0104] pyrite powder 6 binder 15;

[0105] Wherein the pure iron powder has a purity of ≥99% and a particle size of 100 mesh, and the pig iron powder has a purity of ≥95% and a particle size of 100 mesh;

[0106] The carbon content of the graphite powder and the activated carbon powder is more than or equal to 98%, and the particle size is 100 mesh;

[0107] The purity of the copper powder is more than or equal to 90%, and the particle size is 100 mesh;

[0108] The purity of the manganese powder is more than or equal to 98%, and the particle size is 100 mesh;

[0109] The particle d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com