A pasting machine for processing corrugated rubber pads for automobile fuel tanks

A technology for automobile fuel tanks and rubber pads, applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of many manual pasting processes, waste of manpower and resources, bubbles or deflections, etc., to avoid uneven tape. , The effect of improving the qualification rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

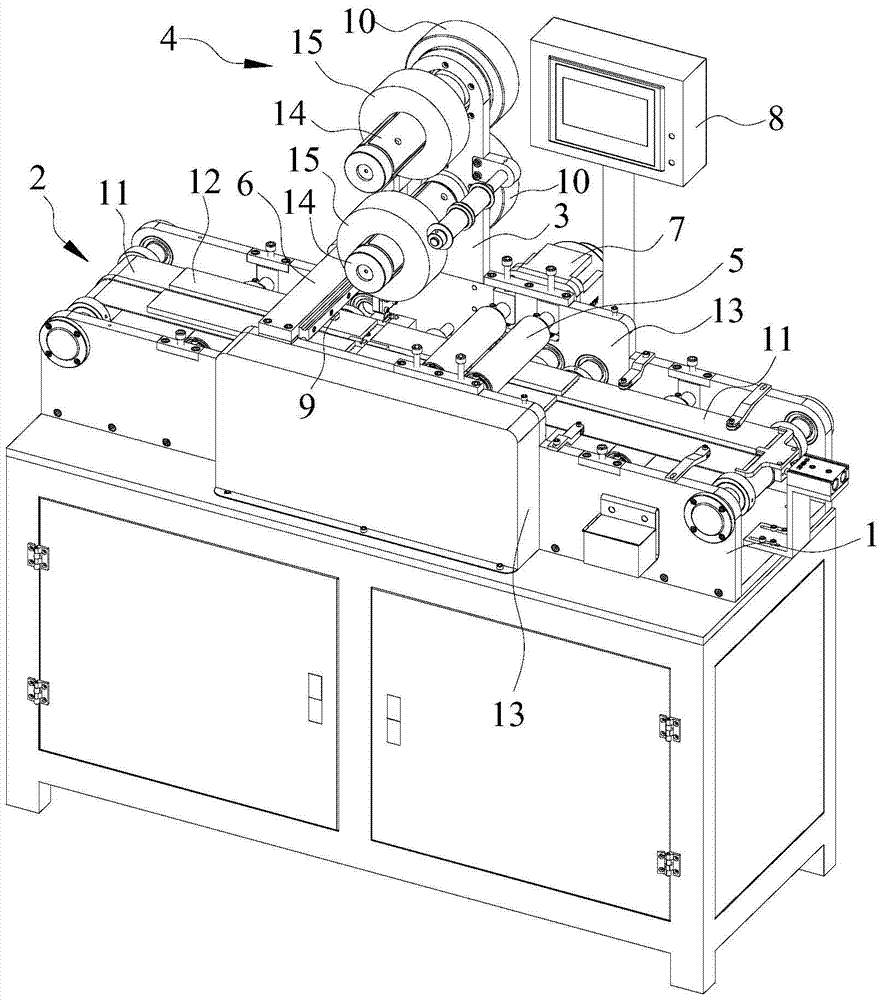

[0024] Pasting machine of present embodiment, as figure 1 As shown, it includes a frame 1, a transmission mechanism 2, a double-sided adhesive sticking mechanism, a cutting part 6, a servo motor 7 and a PLC controller 8.

[0025] Wherein the transmission mechanism 2 is two conveyor belts 11 arranged side by side on the frame 1, and the frame 1 on both sides of the conveyor belt 11 extends upwards with a baffle plate 13 respectively; The tape release mechanism 4 of the surface adhesive tape and the calendering part 5 that presses the double-sided adhesive tape on the surface of the corrugated rubber pad 12, the bracket 3 is fixedly connected to the baffle plate 13 on one side of the frame 1, and the tape release mechanism 4 is connected to the The top of the bracket 3 is positioned above the conveyor belt 11; the calendering part 5 is position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com