Single-screw multi-control type cutter frame structure of dividing and cutting machine

A multi-control and slitting machine technology, which is applied in metal processing and other directions, can solve the problems of high energy consumption and high cost, and achieve the effects of reducing equipment operation energy consumption, saving equipment cost, and reliable and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

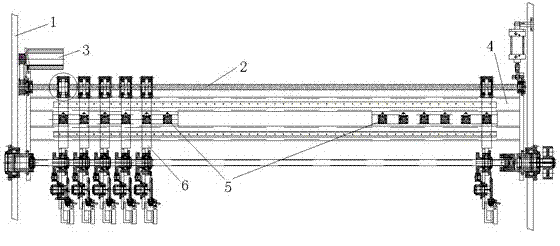

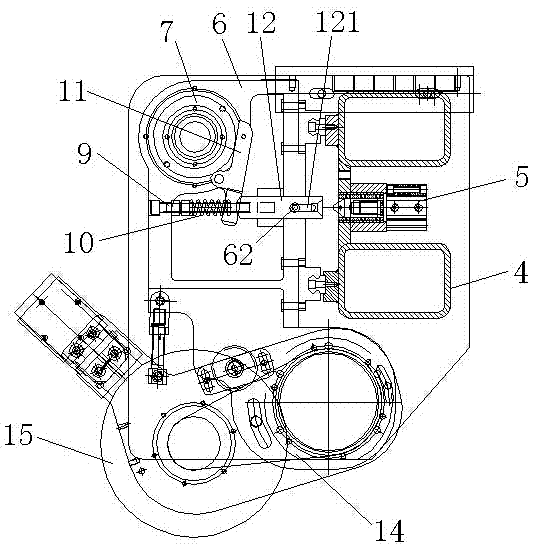

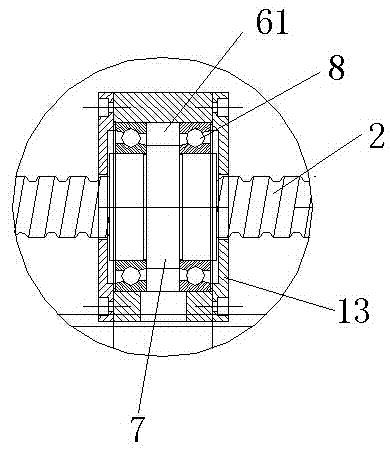

[0030] Embodiment: Most of the existing slitters have been realized to control the slitting distance through the controller and the control program, such as figure 1 As shown in , taking six tool holders as an example, set the figure 1 From left to right in the middle, there are No. 1 knife seat, No. 2 knife seat, No. 3 knife seat, No. 4 knife seat, No. 5 knife seat and No. 6 knife seat. For example, when cutting 2 meters wide paper into 0.5 When the width is 1.2 meters or 1.2 meters, the controller controls the cylinder 5 located above the No. 6 tool holder, so that the push rod of the cylinder 5 loosens the compression structure, so that the pressure plate 11 compresses the nut 7 through the action of the elastic part 10 so that the nut 7 cannot Rotation, and the rotation of the screw rod 2 drives the whole No. 6 knife seat to move. When the distance between the cutting disc 15 on the No. 6 knife seat and the cutting disc 15 on the No. 5 knife seat is measured to be 0.5 mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com