Rotating disc type multiple station drilling machine for processing crankshafts and processing method thereof

A turntable, multi-station technology, used in metal processing machinery parts, crankshafts, metal processing equipment, etc., can solve the problems of easy damage or loss of workpieces, reduce production efficiency, reduce accuracy, etc., to prevent damage or loss, The effect of reducing personnel costs and reducing the number of positioning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

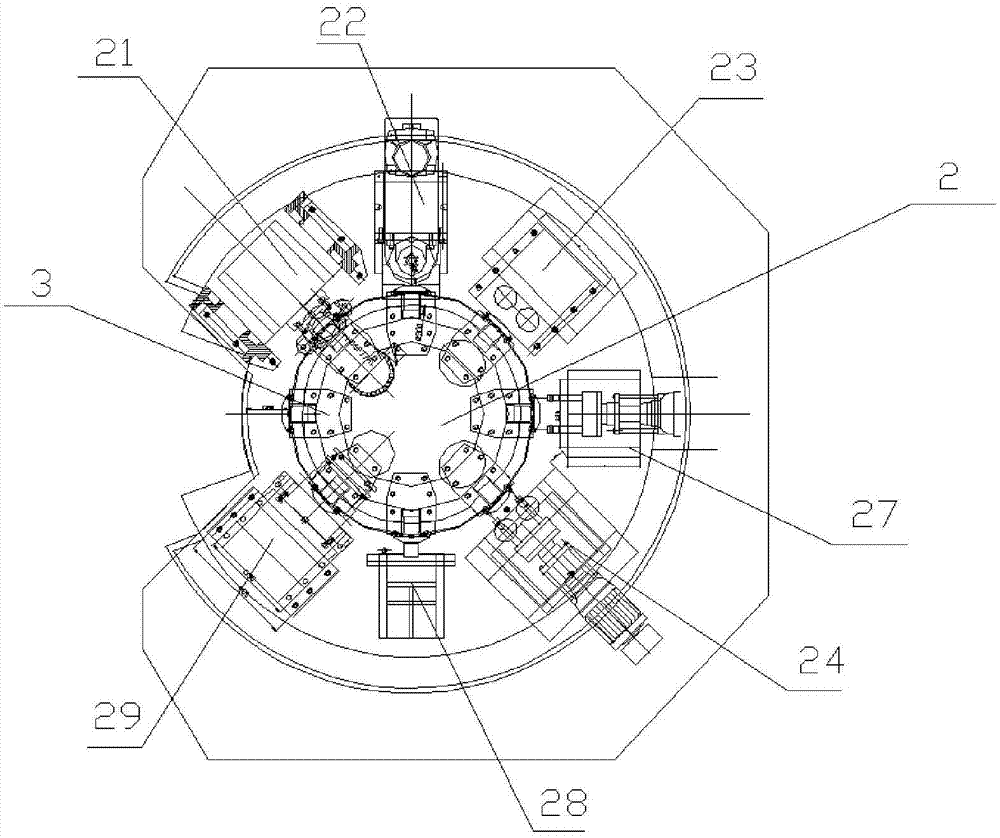

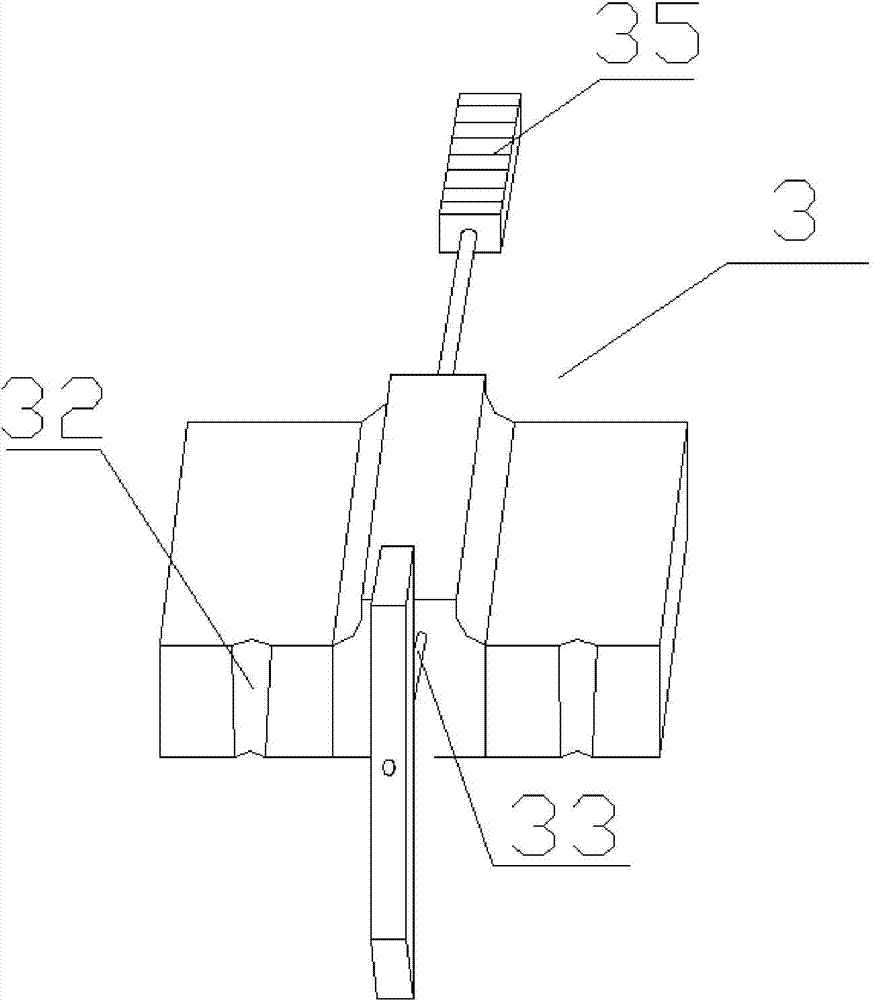

[0036] refer to Figure 1-Figure 10 And embodiment the present invention is described further. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

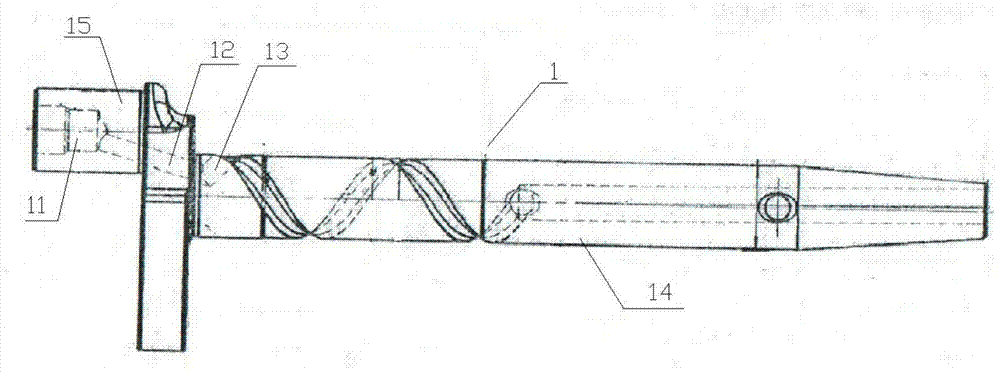

[0037] refer to figure 2 : the workpiece to be processed is crankshaft 1, including major axis 14 and centrifugal part 15. In the production process, a pair of qualified crankshaft 1 often needs to offer axial hole 11 on centrifugal part 15, pass centrifugal part 15 and major axis 14 oil holes and control the length of the crankshaft 1, the oil holes include the axial oil hole 12 and the oblique oil hole 13, meanwhile, in order to produce a crankshaft 1 with higher quality and better precision, the axial oil hole 12 is opened It is necessary to mill the axial oil hole 12 flat before opening the inclined oil hole 13. Before opening the inclined oil hole 13, it is necessary to center the inclined oil hole 13. It is also necessary to chamfer the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com