Multi-degree-of-freedom flexible robot for single-port abdominal minimally invasive surgery

A minimally invasive surgery, degree of freedom technology, applied in the field of surgical robots, can solve the problems of low overall integration of the robot, unable to fully realize the degree of freedom, and the part of the instrument is too simple, to enhance operability and precision, simple structure, Pain-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

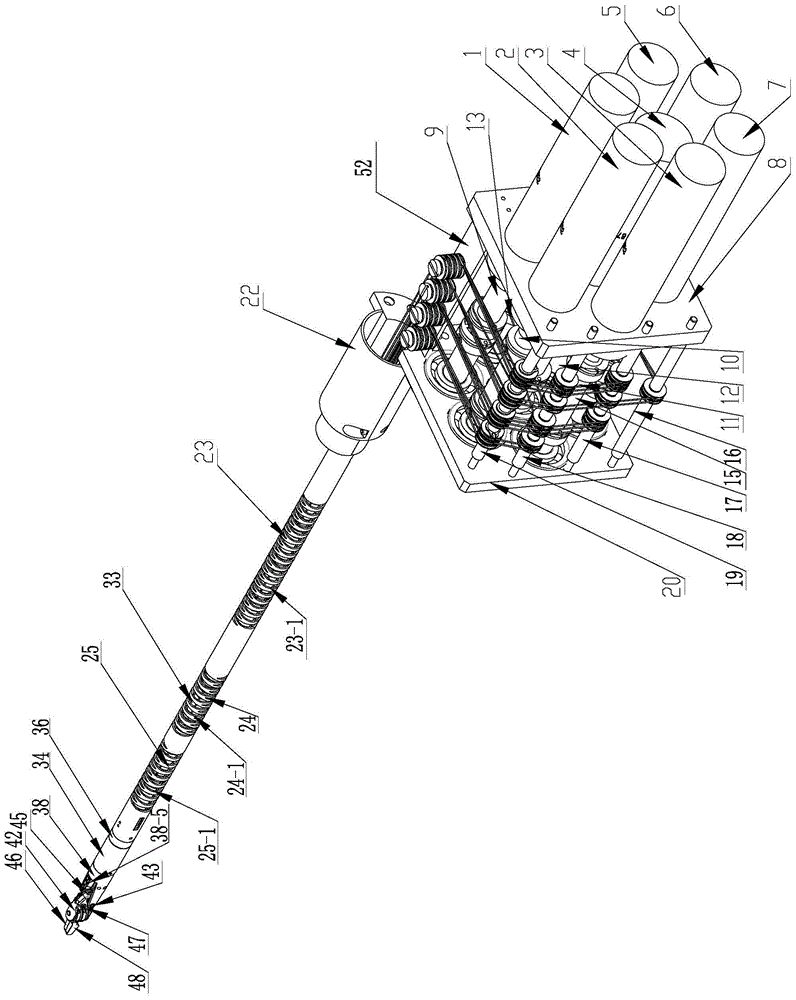

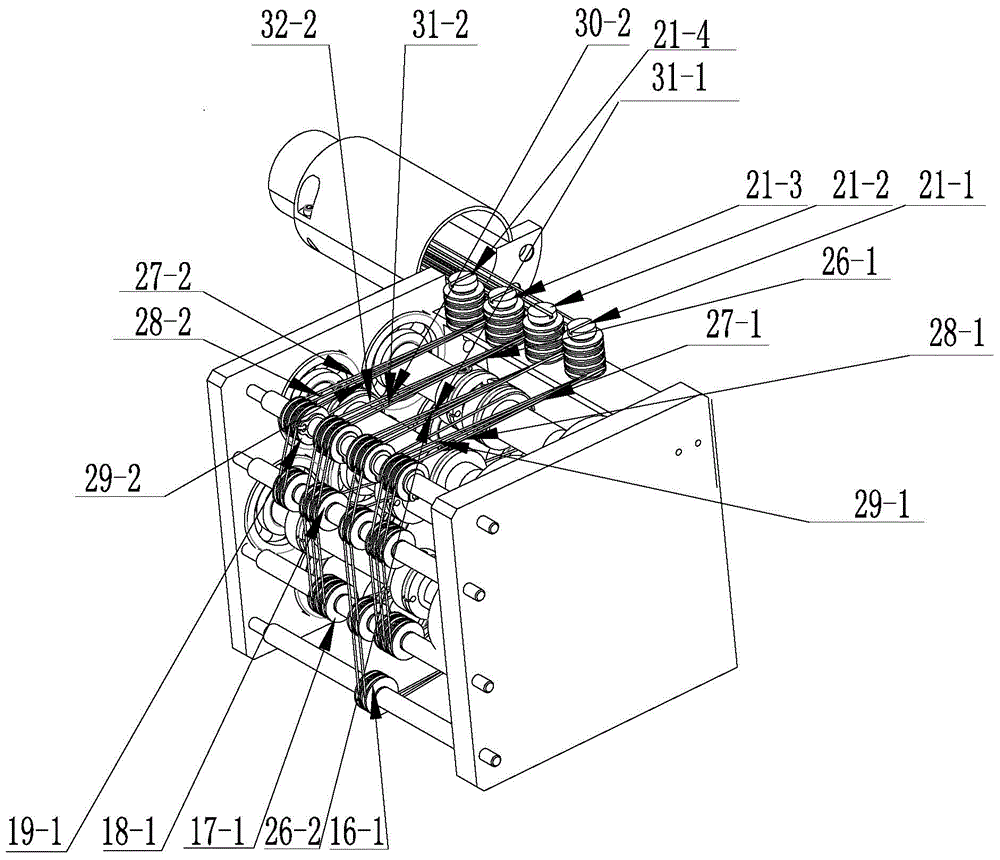

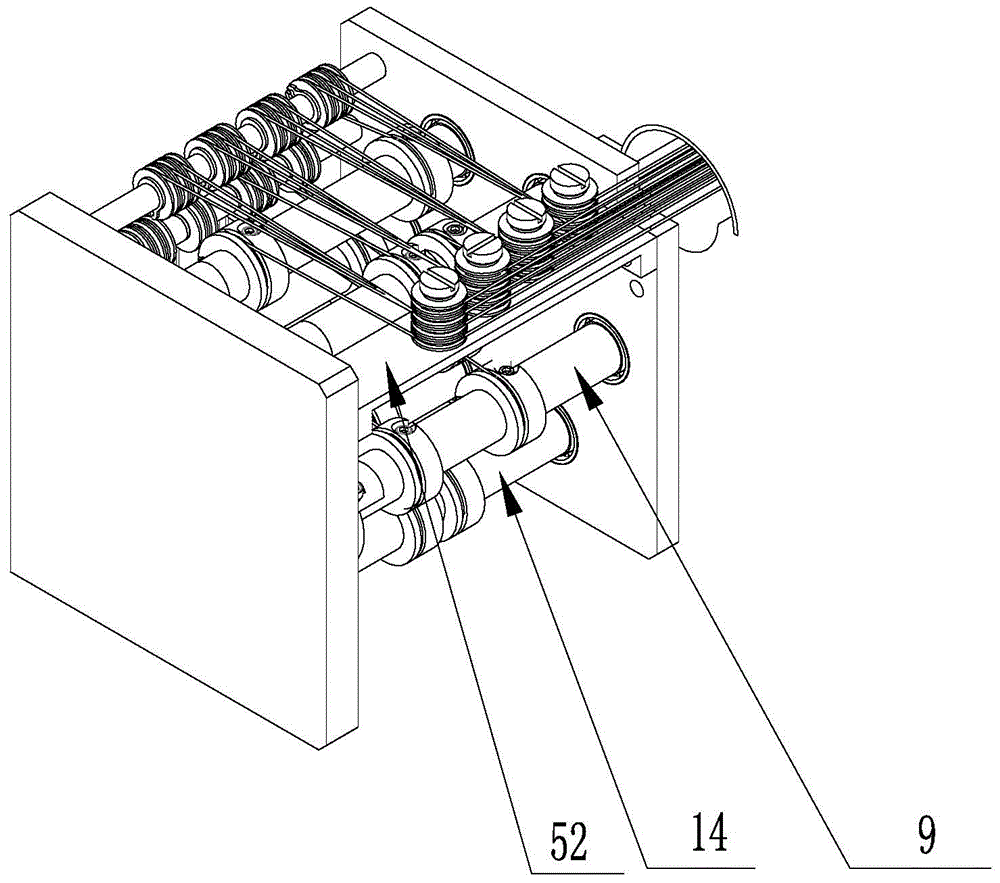

[0022] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, the robot of this embodiment includes a first motor 1, a second motor 2, a third motor 3, a fourth motor 4, a fifth motor 5, a sixth motor 6, a seventh motor 7, and a drive box Rear support plate 8, first motor output shaft 9, second motor output shaft 10, third motor output shaft 11, fourth motor output shaft 12, fifth motor output shaft 13, sixth motor output shaft 14, seventh motor output shaft Output shaft 15, first drive wire guide shaft 16, second drive wire guide shaft 17, third drive wire guide shaft 18, fourth drive wire guide shaft 19, drive box front end support plate 20, first flexible arm guide wheel set 21-1, the second flexible arm guide wheel set 21-2, the third flexible arm guide wheel set 21-3, the fourth flexible arm guide wheel set 21-4, the flexible arm clamping tube 22, the first incision flexible arm 23. Second incision flexible arm 24, third incision flexible ...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination figure 1 and Figure 4 Describe this embodiment, the wrist threading barrel 38 of this embodiment is made into one by base 38-1 and two connecting ears 38-2, and base 38-1 is provided with first guide wheel fixing post 38-3, second Guide wheel fixed column 38-4, the 3rd guide wheel fixed column 38-5 and the 4th guide wheel fixed column 38-6, the inwall of the first guide wheel fixed column 38-3 is provided with two guide wheels one, the second The inwall of guide wheel fixed column 38-4 is provided with a guide wheel two, and the sidewall of the second guide fixed column 38-4 is provided with two guide wheels five, and the inwall of the third guide wheel fixed column 38-5 is provided with Two guide wheels three, are provided with a guide wheel four on the inwall of the 4th guide wheel fixed column 38-6, are provided with two guide wheels six on the sidewall of the 4th guide wheel fixed column 38-6, the first guide wheel Th...

specific Embodiment approach 3

[0039] Specific implementation mode three: combination figure 1 Note that the first flexible arm 23 of this embodiment is provided with several first V-shaped incisions 23-1 in the same direction, and the second flexible arm 24 is provided with several second V-shaped incisions 24-1 in the same direction. The third flexible arm 25 has several third V-shaped notches 25-1 in the same direction, the first V-shaped notch 23-1 on the first flexible arm 23 and the third V-shaped notch 25 on the third flexible arm. -1 direction is the same, the angle between the direction of the second V-shaped notch 24-1 and the first V-shaped notch 23-1 is 90°. The advantage of the above structure is that the arc-shaped bending movement of each flexible arm is realized through the cutout of each flexible arm, which enhances the movement performance of the mechanical arm in a limited working space. The multi-degree-of-freedom bending motion of the manipulator is realized through the combination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com