Injection-molded optical transparent cover for surveillance camera

A monitoring camera, optically transparent technology, applied in the direction of optics, camera body, camera, etc., can solve problems such as adverse effects on camera imaging quality, and achieve the effect of avoiding the formation of transition lines and excellent imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with combined drawings, so that those skilled in the art can understand the present invention.

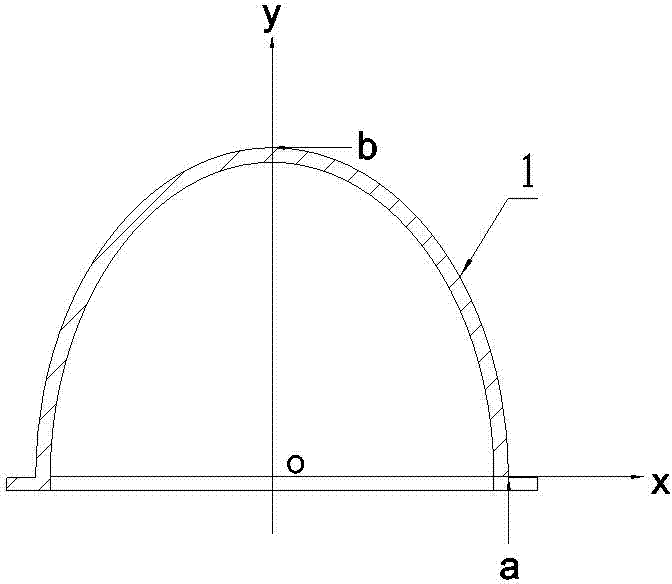

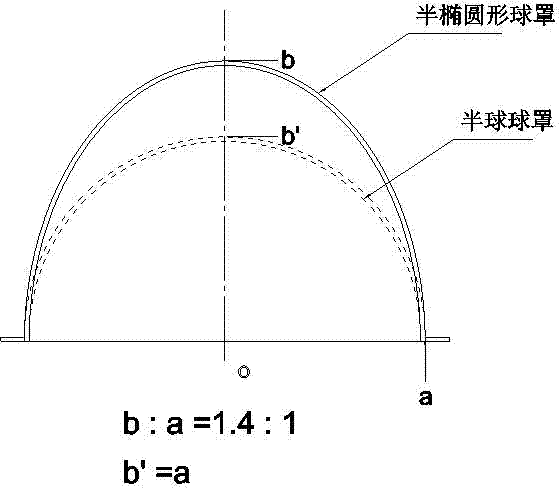

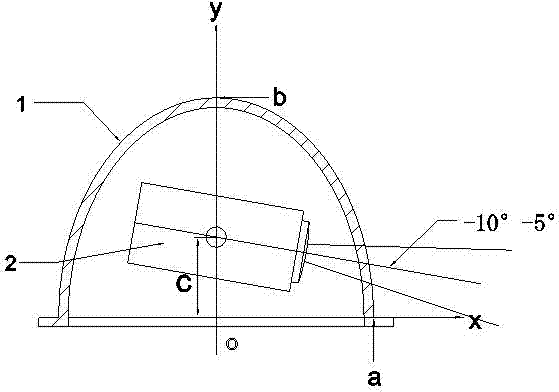

[0019] Such as Figure 2-4 As shown, an injection-molded optically transparent cover for monitoring cameras is the same as the existing dome cover, which is a shell, the difference is that it is a half ellipse dome cover, and its curve equation is ( (b>a>0, y≥0)), the coordinate origin is O(0, 0), where: the height of the dome is b, the radius of the opening is a, 1.1:1≤b:a≤1.4:1, As the ratio of b:a increases, the difference between the elliptical protective cover and the ordinary dome cover gradually increases, and the circularity of the elliptic function gradually deviates. It is recommended that 1.1:1≤b:a≤1.4:1. In addition, the improvement effect of this invention on the horizontal angle is not very significant in the small ball machine, mainly because the focal length of the small ball machine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com