Device and method for measuring thermo-optical coefficient of thin-film material

A thin-film material, thermo-optic coefficient technology, applied in the field of testing, can solve the problems of difficult determination of physical parameters, affecting measurement accuracy, discontinuous testing process, etc., to achieve the effect of wide application, easy implementation and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

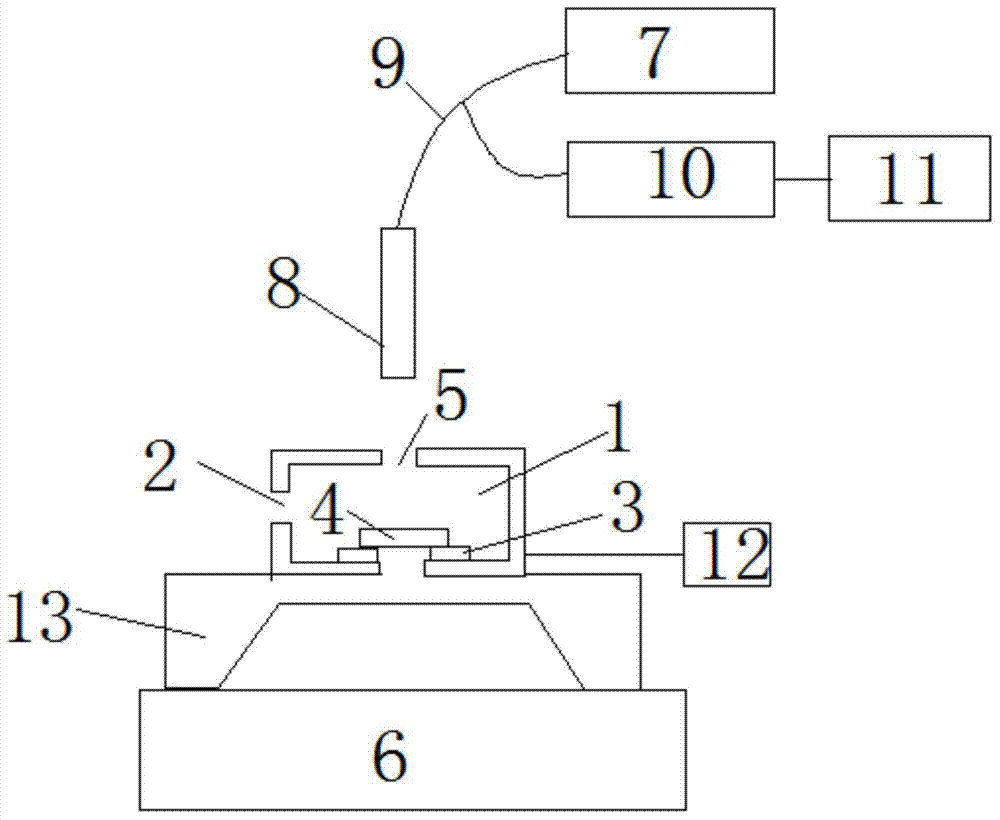

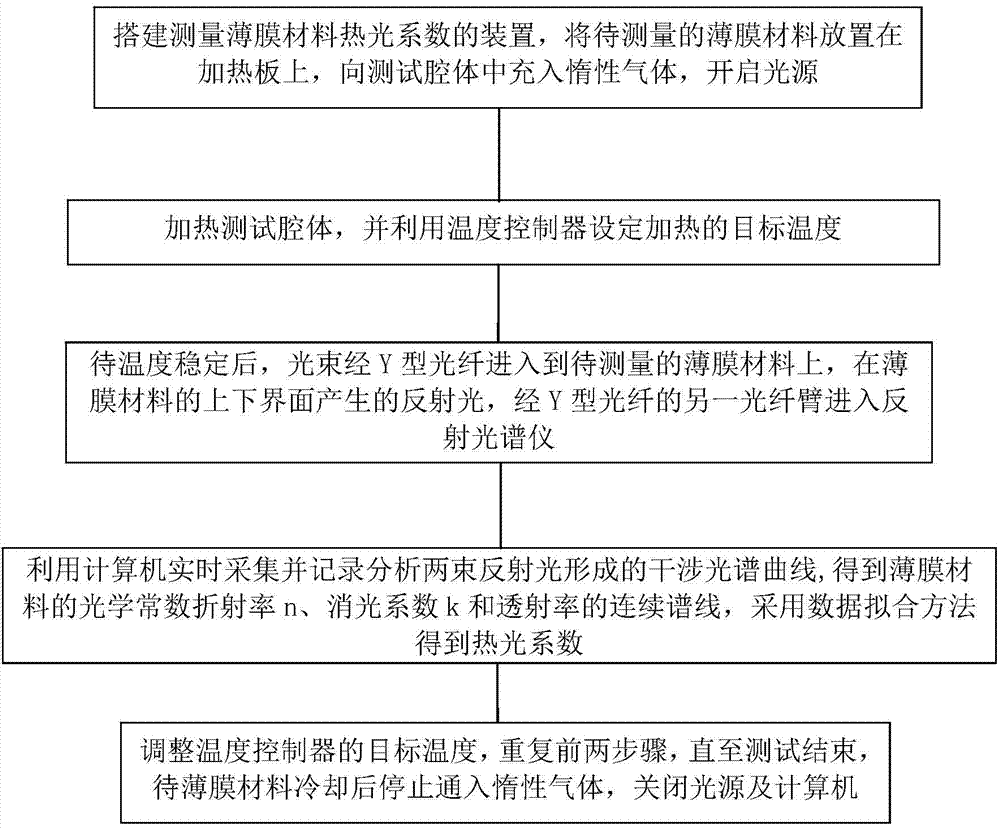

[0035] Such as figure 1As shown, in the device for measuring the thermo-optic coefficient of thin film materials in this example, the air inlet of the heating unit is located on the side wall of the box, the light opening is located on the top of the box, and the heating plate is arranged at the bottom of the box. The heating plate is silicon Rubber heating plate 3. The silicone rubber heating plate 3 can ensure that the film material 4 to be measured is heated evenly. Silicone rubber heating plate has rapid heating, high thermal efficiency, water resistance, acid resistance, alkali resistance, high electrical insulation strength, wide temperature range, from -60°C to 200°C and self-insulation, no open flame, great for heat preservation and heat insulation in technology For simplification, easy to use and other features.

[0036] The light opening 5 is located above the heating plate, and the thin film material 4 to be measured is erected on the heating plate to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com