A method for extracting air and heat from a rotary kiln and a rotary kiln system capable of extracting air and heat

A technology of rotary kiln and cement rotary kiln, applied in the field of rotary kiln system, can solve the problems of affecting the quality of clinker, clogging, abnormal operation of kiln conditions, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

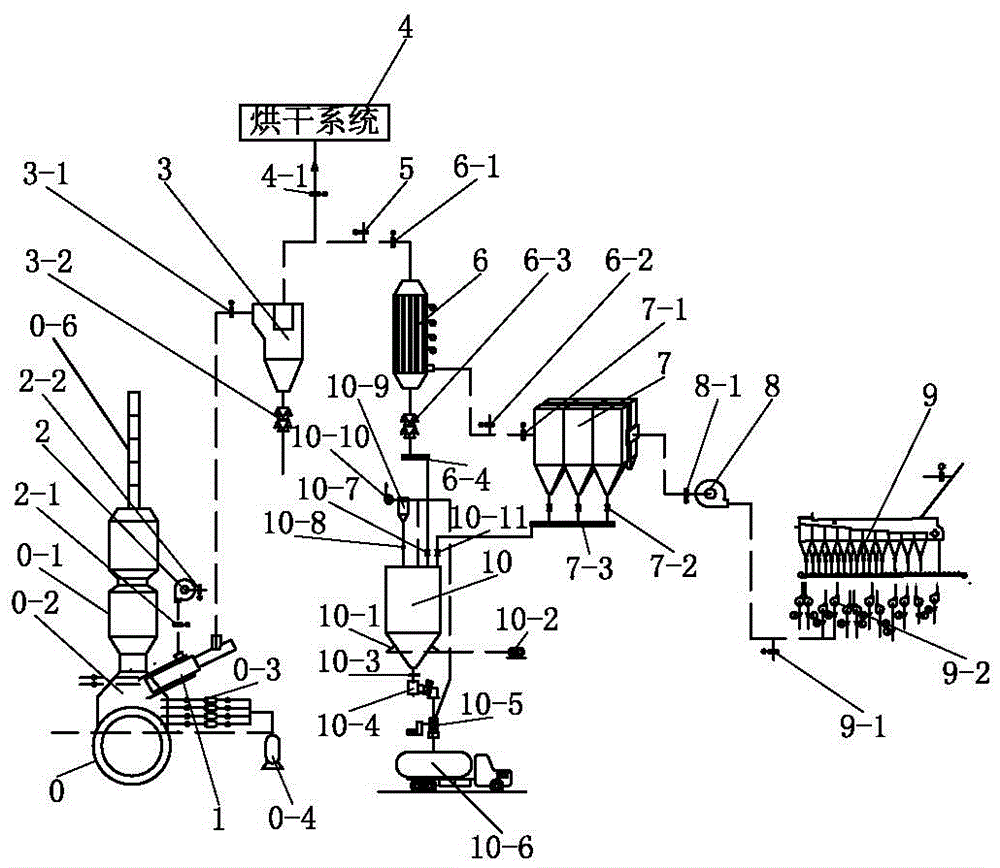

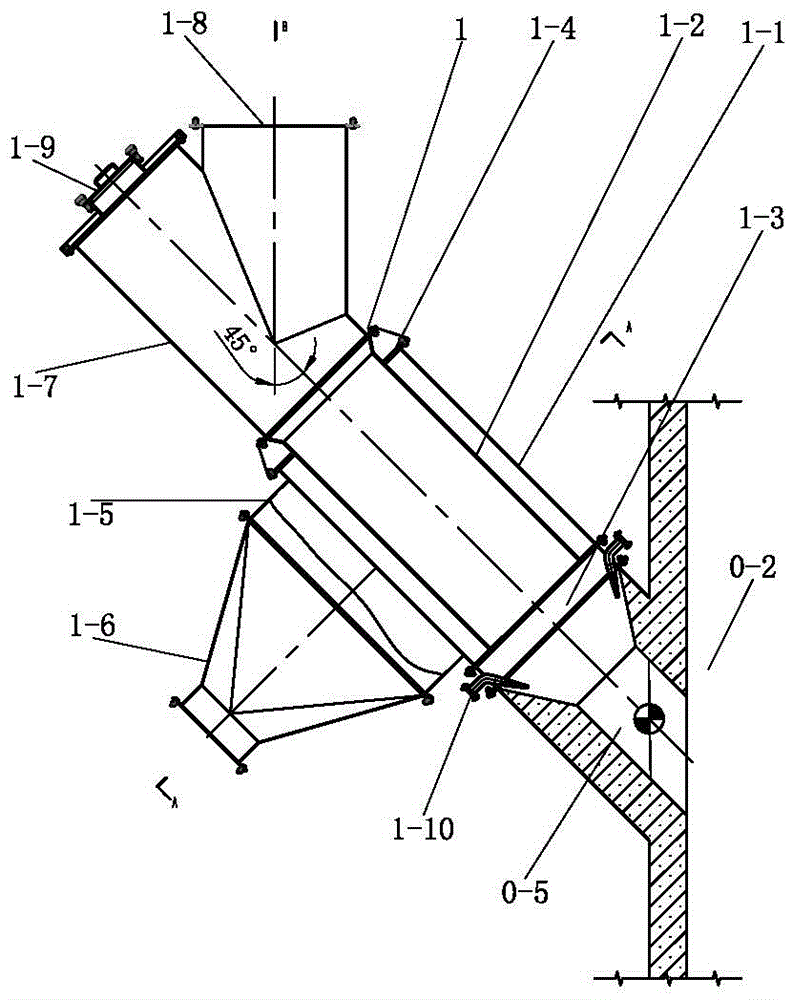

[0094] Such as figure 1 As shown, the present invention provides a method for extracting air and heat from a rotary kiln, in which hot flue gas is taken out from the rotary kiln 0, and the hot flue gas is taken out from the smoke chamber 0-2 at the kiln tail of the rotary kiln 0 .

[0095] As a preference, the temperature of the hot flue gas taken out from the tail smoke chamber of the rotary kiln 0 is 950°C to 1200°C. This is beneficial to discharge more chlorine ions in smoke chamber 0-2.

[0096] This embodiment adopts the technical means that the hot flue gas is taken out from the smoke chamber at the tail of the rotary kiln, so hot flue gas with a higher temperature can be obtained, and the temperature of the hot flue gas is 950 degrees Celsius to 1200 degrees Celsius , the hot flue gas at a higher temperature can dry the substitute raw materials with high water content, it is not necessary to use a coal-fired supplementary combustion furnace as a drying heat source, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com