Stirling engine and cup cover and cup with same

A Stirling engine and cup cover technology, which is applied in the field of cup covers and cups, can solve the problems of poor symmetry of the Stirling engine, high height of the Stirling engine, and design limitations of hot cylinder parameters, etc., and achieve good market prospects and rich Structural type, the effect of facilitating reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

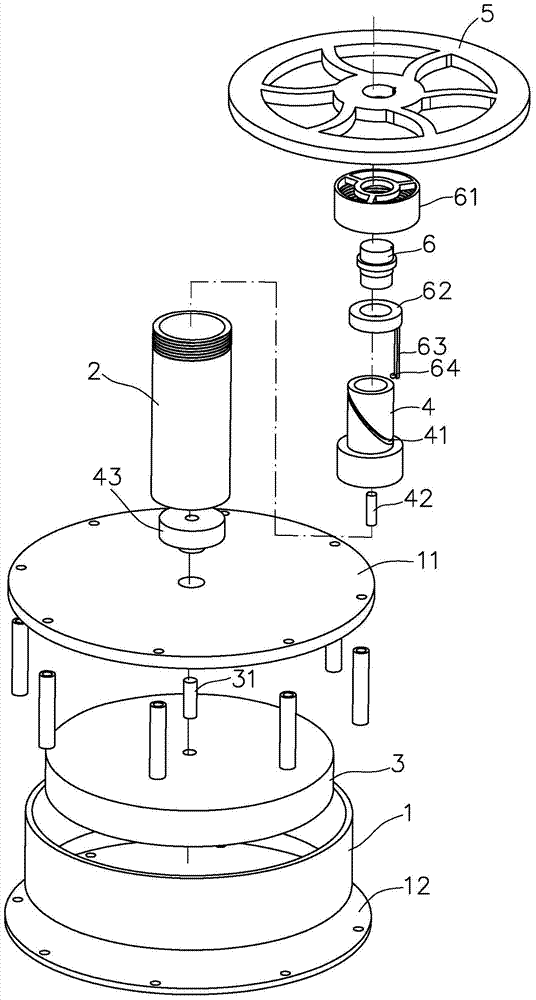

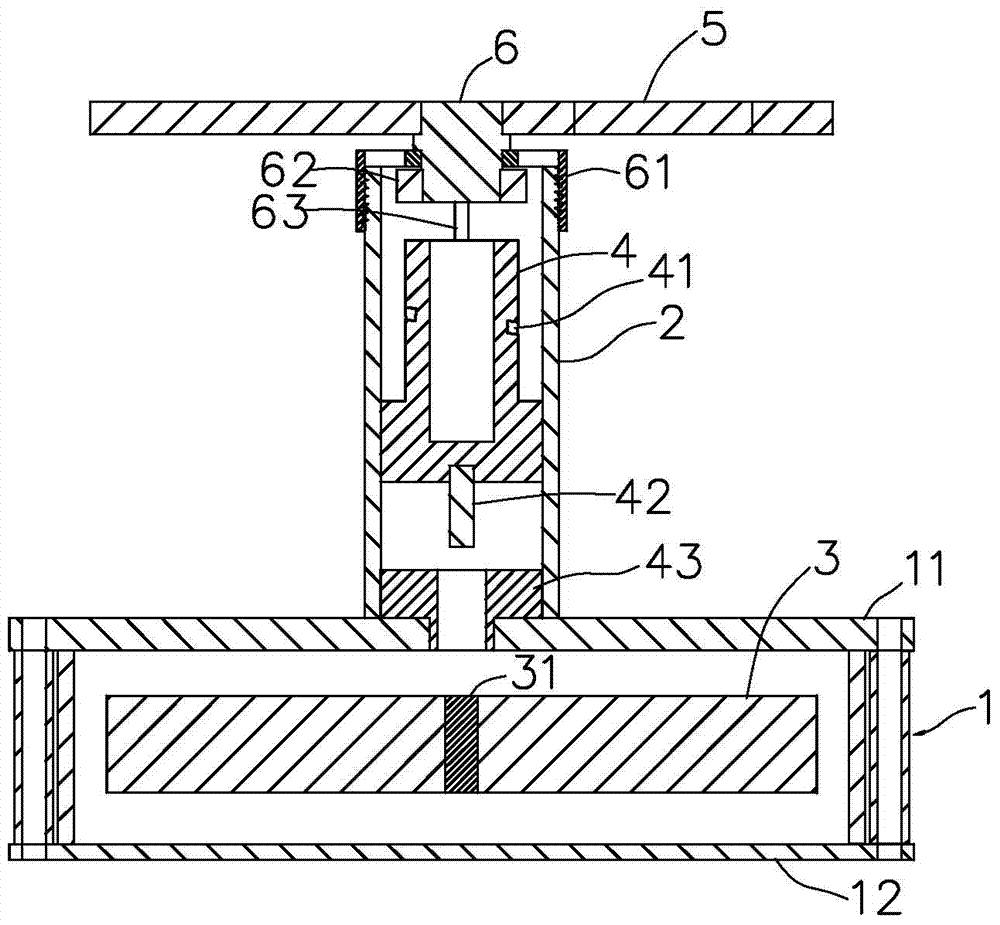

[0040] Example 1, such as figure 1 , figure 2 and image 3 As shown, the Stirling engine 10 in this embodiment includes a first cylinder 1, a second cylinder 2, a gas displacement piston 3 and a power piston 4, the lower end surface of the first cylinder 1 forms a heat absorbing surface 12, and the upper end surface forms a heat dissipation surface 11. The second cylinder 2 is in communication with the first cylinder 1; the moving piston 3 is set in the first cylinder 1 so that it can move up and down; the power piston 4 is set in the second cylinder 2 so that it can move up and down.

[0041] The bottom end of the power piston 4 is provided with a magnet 42 and a guide groove 41 is obliquely formed on the outer periphery. Of course, it is also possible to form the middle part of the power piston 4 as hollow and form the guide groove 41 on the inner wall. However, it is preferable to arrange it on the outer periphery.

[0042] The air-moving piston 3 is provided with a dri...

Embodiment 2

[0045] Example 2, such as Figure 4As shown, the cup in this embodiment includes a cup body 100 and a cup cover 102 covering the cup body 100. The cup cover 102 includes a body 7 and a heat insulating sleeve 8 disposed in the body 7. The middle part of the cup cover 102 has a The mounting hole for the first cylinder 1 of the Stirling engine 10 to extend into, the heat absorbing surface 12 and the heat dissipation surface 11 of the Stirling engine 10 are adapted to the upper end surface and the lower end surface of the body 7 respectively, and the outer side of the cup cover 102 is detached A cover body 101 is provided in a conventional manner, and the Stirling engine 10 is located in the cover body 101 . For the structure of the Stirling engine 10, refer to Embodiment 1. During use, add hot water in the cup body 100, take off the cover body 101, put the cup cover 102 on the cup body 100, after a few minutes, drive the flywheel 5, and the flywheel 5 can continue to rotate.

Embodiment 3

[0046] Example 3, such as Figure 5 As shown, the cup in this embodiment includes a cup body 100 and a cup cover 102 covering the cup body 100. The cup cover 102 includes a body 7 and a heat insulating sleeve 8 disposed in the body 7. The Stirling engine 10 The cooling surface 11 and the body 7 are one piece, the inner wall of the heat insulation sleeve 8 forms the first cylinder side wall of the Stirling engine, and the heat absorption surface 12 of the Stirling engine 10 is embedded in the lower end surface of the heat insulation sleeve 8 . Refer to Example 2 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com