Method for continuously preparing high-bulk density methionine crystals

A technology of methionine and bulk density, applied in the field of chemical production, can solve the problems of affecting the crystallization process, foaming, easy generation of bubbles, etc., and achieve the effects of good stability, high efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

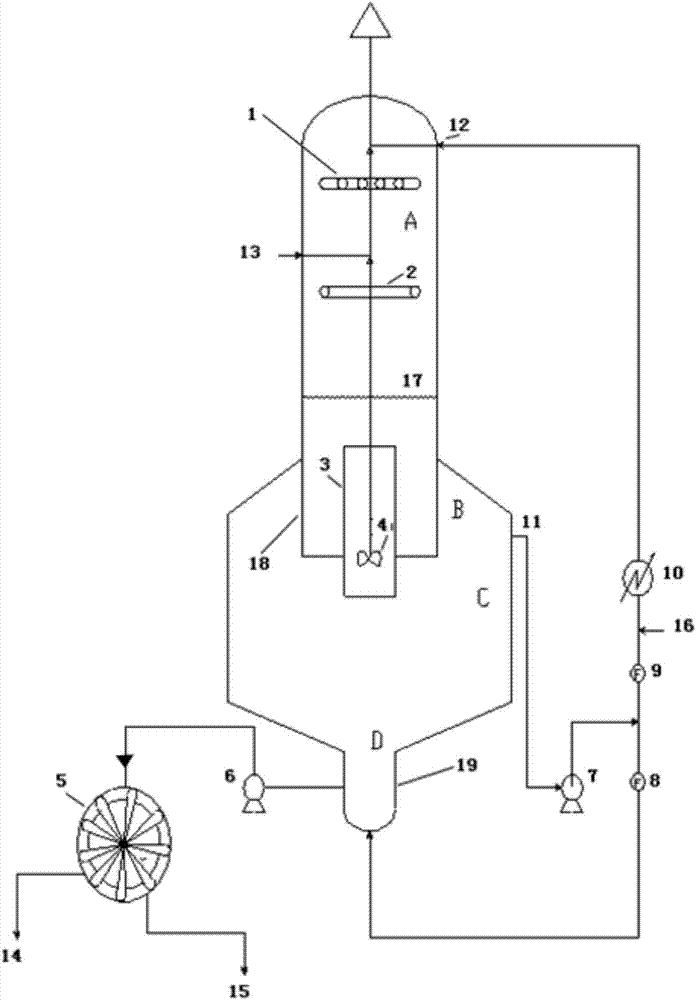

[0064] The DTB neutralization crystallizer with the gas phase neutralization section of the present invention has the following structure: the volume of the liquid phase is 1m 3 , designed according to the proportion of conventional DTB structure; the volume of the gas phase is 0.6m 3 , is a cylinder with a diameter of 600mm and a height of 2200mm with an elliptical head, with a liquid distributor on the upper part and a carbon dioxide gas distributor on the lower part.

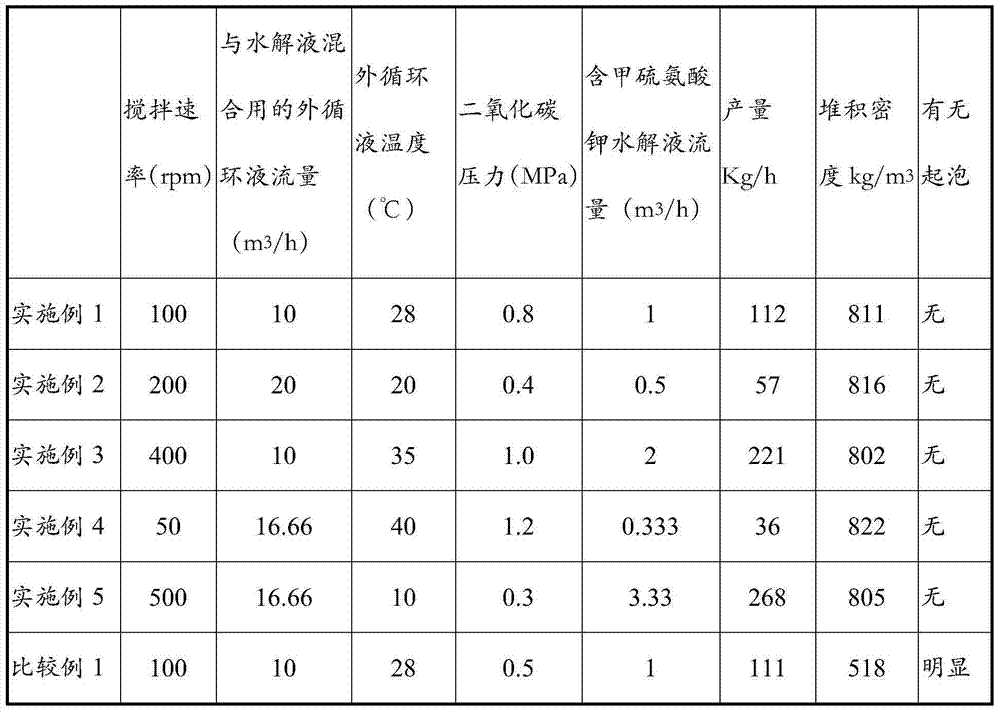

[0065] Add 0.9m 3 Saturated solution of methionine, and then add 10Kg of methionine seed crystals that are ground to less than 10 microns. Turn on the crystallizer to stir, the stirring rate is 100rpm, turn on the external circulation pump, and adjust the flow rate of the external circulation liquid entering the washing leg to 1.6m 3 / h, the flow rate of the external circulation fluid mixed with the hydrolyzate containing potassium methionate is 10m 3 / h. After the circulating flow is stable, turn on the ...

Embodiment 2

[0069] Add 0.9m 3 Saturated solution of methionine, and then add 10Kg of methionine seed crystals that are ground to less than 10 microns. Turn on the crystallizer to stir, the stirring rate is 200rpm, turn on the external circulation pump, and adjust the flow rate of the external circulation liquid entering the washing leg to 1.5m 3 / h, the flow rate of the external circulation fluid mixed with the hydrolyzate containing potassium methionate is 20m 3 / h. After the circulating flow is stable, turn on the circulating cooling to keep the temperature stable at 20°C. Inject carbon dioxide from the gas distributor to make its pressure reach 0.4Mpa. At this time, the hydrolyzed solution containing 19% potassium methionate at 20°C is introduced, and the flow rate is 0.5m 3 / h (equivalent to a residence time of 2 hours), mixed with the external circulation material, cooled to 18°C by the cooler, and then enters the liquid distributor at the top of the crystallizer, and the liqui...

Embodiment 3

[0073] Add 0.9m 3 Saturated solution of methionine, and then add 10Kg of methionine seed crystals that are ground to less than 10 microns. Turn on the crystallizer to stir, the stirring rate is 400rpm, turn on the external circulation pump, and adjust the flow rate of the external circulation liquid entering the washing leg to 4m 3 / h, the flow rate of the external circulation fluid mixed with the hydrolyzate containing potassium methionate is 10m 3 / h. After the circulating flow is stable, turn on the circulating cooling to stabilize the temperature at 35°C. Inject carbon dioxide from the gas distributor to make the pressure reach 1.0Mpa. At this time, the hydrolyzate containing 19% of potassium methionate at 35°C is introduced, and the flow rate is 2m 3 / h (equivalent to a residence time of 0.5 hours), mixed with the external circulation material, cooled to 30°C by the cooler, and then enters the liquid distributor at the top of the crystallizer, and the liquid is spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com