Method for preparing flame retardant grade magnesium hydroxide

A technology of magnesium hydroxide and flame-retardant grade, which is applied in the field of preparation of flame-retardant magnesium hydroxide, which can solve the problems of pollution, a large amount of magnesium oxide, waste environment, etc., and achieve the effects of simple equipment, environmental protection and waste avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

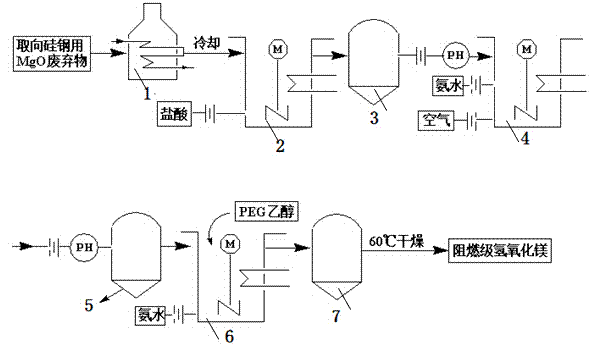

[0019] like figure 1 As shown, the present invention discloses a method for preparing flame-retardant magnesium hydroxide. The specific process is as follows: calcining the magnesia waste for oriented silicon steel in a muffle furnace 1 at 650°C for 5 hours to remove the carbon inside; then cooling, Under the condition of heating to 60°C and constant stirring, dissolve with hydrochloric acid in the dissolution tank 2, and the excess of hydrochloric acid is 1.25 times; then precipitate in the first sedimentation tank 3, the settling time is 5h, and remove the insoluble matter, including B, C, TiO 2 etc.; then add ammoniacal liquor in the above-mentioned solution in the first reaction tank 4, the proportioning of ammoniacal liquor is strong ammoniacal liquor: water=1:50, and the ammoniacal liquor amount is 1 / 25 of solution amount, and constantly feeds compressed air (makes Fe 2+ converted to Fe 3+ ), by controlling PH=9 to make Fe 3+ completely precipitated while Mg 2+ No pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com