Trackless door operator applied in round hole

A kind of rail door machine and round hole technology, which is applied to cranes, cranes, traveling gears of trolleys, etc., can solve the problems of large weight of a single sleeper and inconsistency in dismantling time, so as to enhance adaptability, controllable dismantling time, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

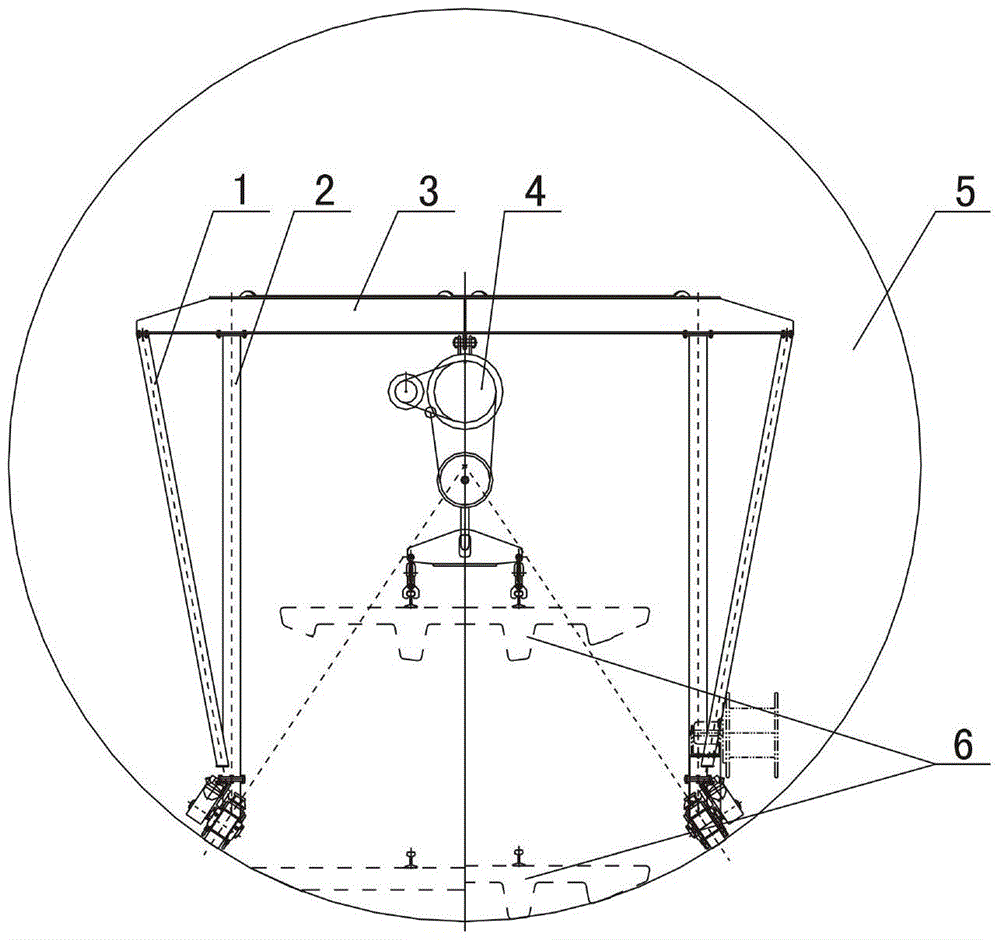

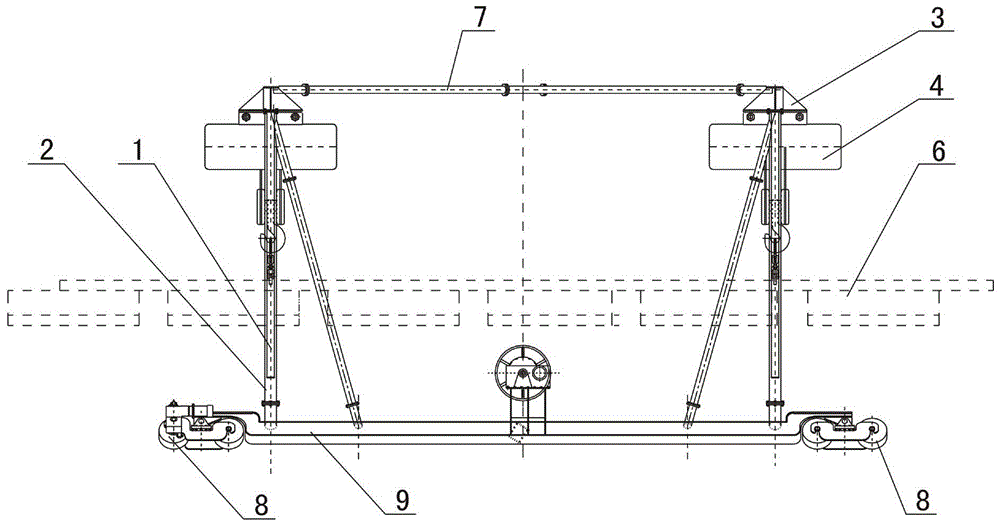

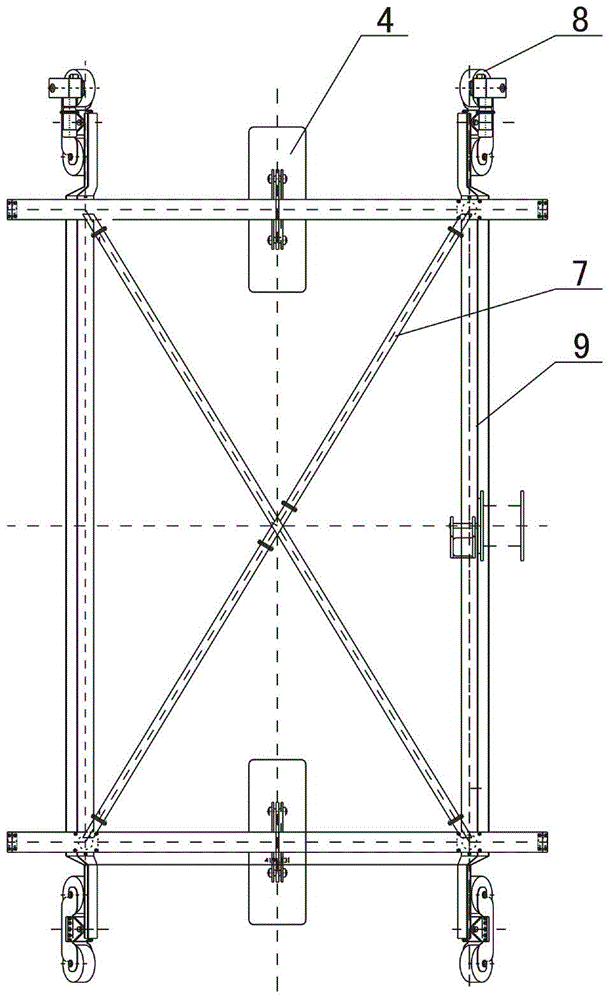

[0023] like figure 1 , figure 2 , image 3 and Figure 7 As shown, the trackless door machine applied in the round hole according to the present invention includes a suspension beam 3, a connecting beam 7, a lower beam 9, a column 2, a rigid frame chord 1, a lifting device 4 and a solid rubber wheel 8, and the column 2 is installed Between the lower beam 9 and the hanging beam 3, the connecting beam 7 is installed above the hanging beam 3, the lifting device 4 is installed below the hanging beam 3, the lower part of the column 2 is connected with the lower end of the rigid frame chord 1, and the rigid frame chord The upper end of the bar 1 is connected with the suspension beam 3, the angle between the column 2 and the rigid frame chord 1 is 10-20°, and the angle connection structure between the column 2 and the lower beam 9 is 100-175° (see Figure 6 ); two lower beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com