Curtain Wall Column Structure and Curtain Wall System

A curtain wall and column technology, applied in the field of component curtain wall system, can solve the problems of low construction efficiency, high cost, limited installation height of the curtain wall, etc., and achieve the effect of improving construction efficiency, good quality, safe and reliable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

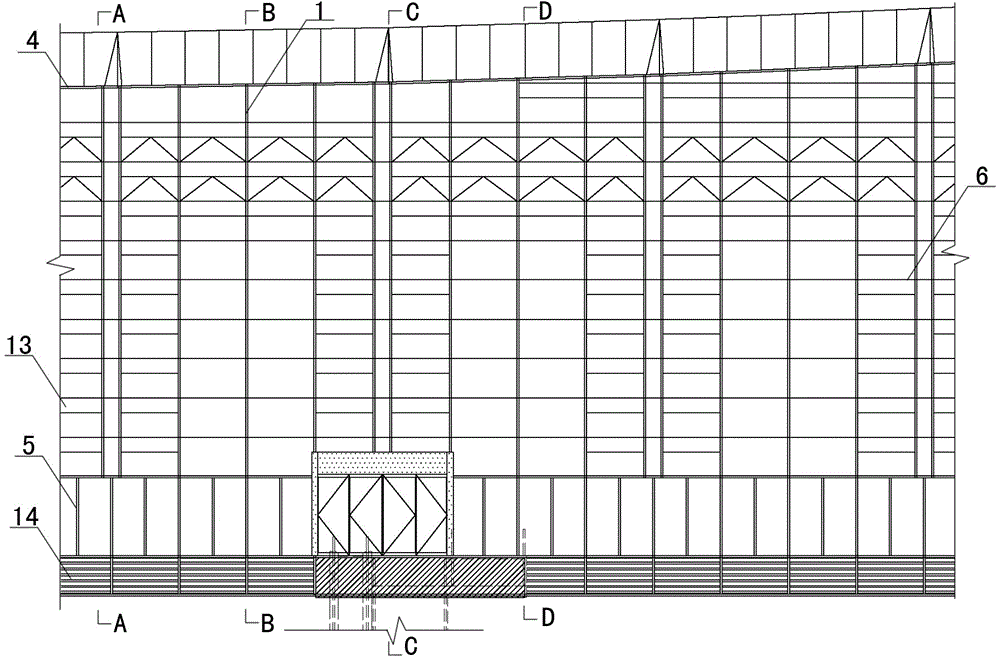

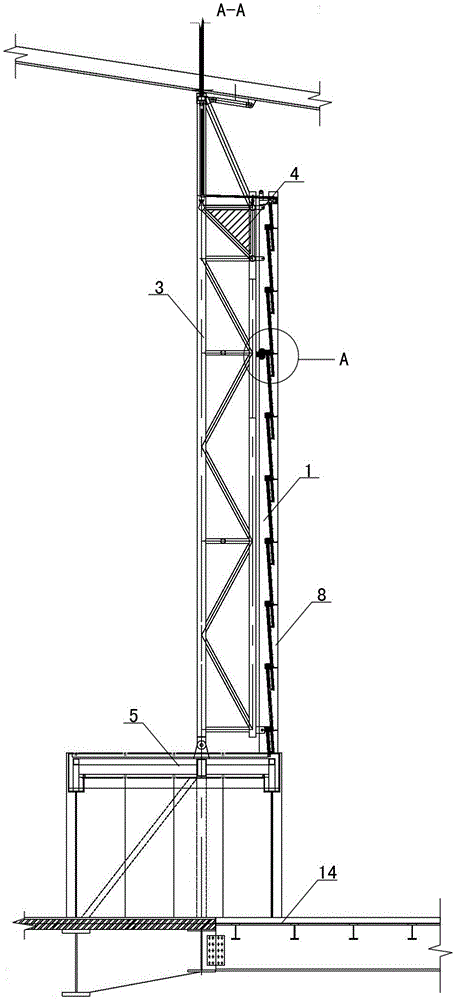

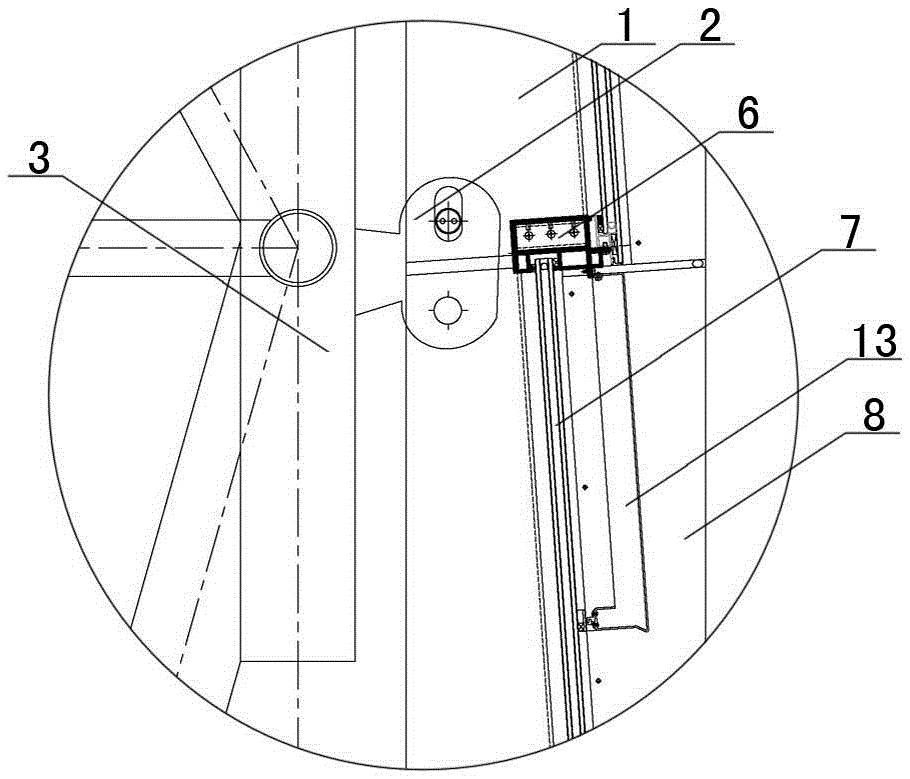

[0033] Examples see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 As shown in this curtain wall column structure, the column 1 is formed by butt joints of sawtooth-shaped column sections vertically and sequentially. One end of the column section is narrow and the other end is wide, and one of the two sides connecting the narrow side and the wide side It is a vertical straight side, and the other is a zigzag side. The adjacent column sections are connected to each other through the mortise and tenon connection between the narrow end and the wide end. The sawtooth of the column section is a right triangle, the angle between the hypotenuse of the sawtooth and the horizontal side is 70°-90°, and each column section has two to ten sawtooth; the column sections are connected with ears through double holes The plates 2 are connected, and at least one of the holes is a vertically elongated hole to facilitate temporary adjustment and ensure the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com