Automatic scrapping of safety syringe needles

A technology for safe syringes and needles, which is applied in the direction of hypodermic injection devices, needles, and devices introduced into the body, etc. It can solve the problems that needles cannot be destroyed automatically, threaten the safety of patients' lives and property, and infringe consumers' rights and interests, so as to protect life and property Safety, prevention of irregular operation, and effect of solving repeated use problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

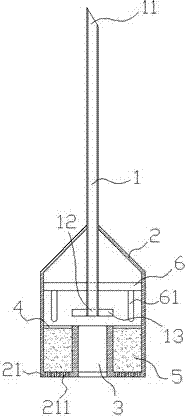

[0012] exist figure 1 In the shown embodiment, the needle of the automatic scrap safety syringe includes a hard needle tube 1 and a needle seat 2; at the center of the bottom end of the needle seat 2, there is an inwardly extending connecting port for connecting the needle barrel 3. On the end surface of the bottom end 21, there are vent holes 211 arranged equidistantly along the circumference of the connection port 3; An annular sealing diaphragm 4; the annular space surrounded by the sealing diaphragm 4 and the bottom end 21 of the needle base 2 is filled with a solid desiccant 5; a discoloration powder is mixed in the solid desiccant 5 ; A piston plate 6 parallel to the sealing diaphragm 4 is slidably installed in the needle seat 2; the needle tube 1 is vertically fixed on the piston plate 6; The top end of the needle tube 1 protrudes, the tail end 12 of the needle tube 1 runs through the piston plate 6, and an annular baffle 13 is also sleeved on the tail end 12 of the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com