Okra capsule and preparation method thereof

A technology of okra and capsules, which is applied in the field of food processing, can solve the problems of not fully exerting the medicinal value of okra, and achieve the effects of being convenient to take and to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

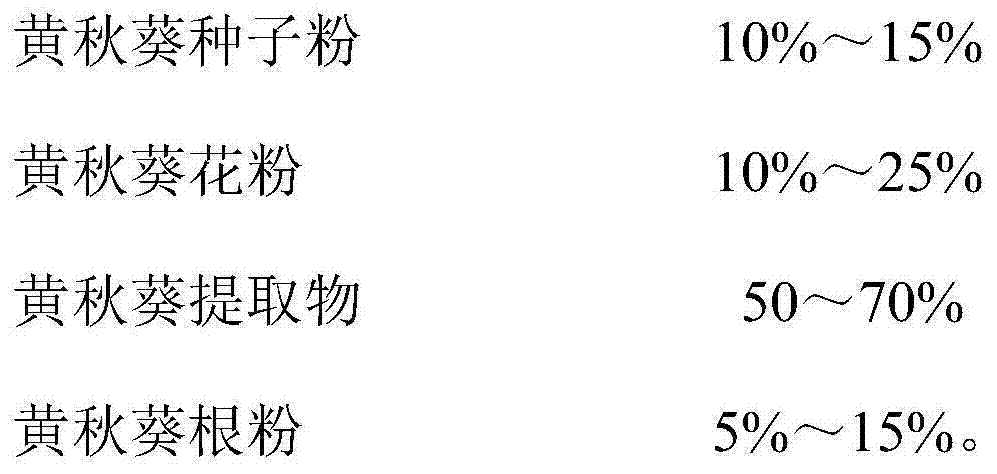

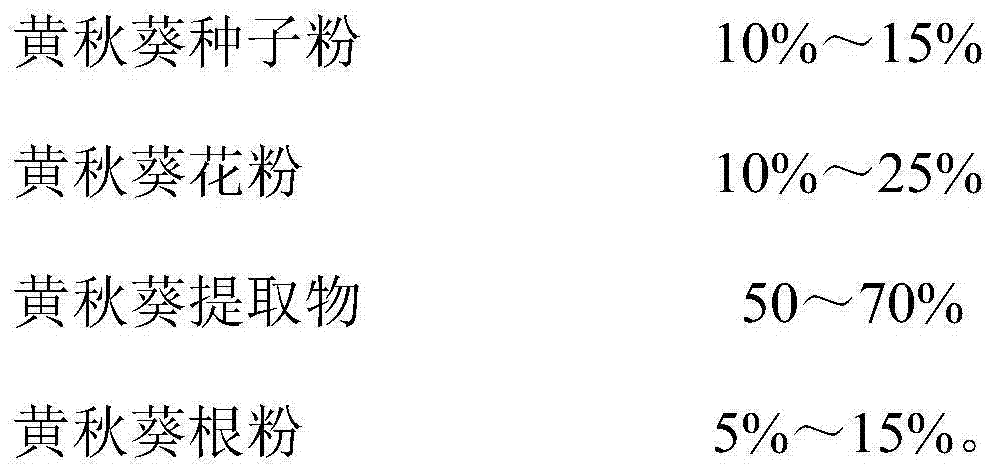

[0022] The invention provides an okra capsule, the main components and mass percentages of which are: okra seed powder 10%, okra pollen 25%, okra extract 50%, and okra root powder 15%. The preparation process is:

[0023] Prepare okra seed powder: select mature okra seeds, wash with water, dry at 35°C, stir-fry at 90°C for 1 hour, and grind the fried seeds into a powder with a particle size of 20um;

[0024] Prepare okra pollen: take okra flowers in the early morning, and directly bake them in an oven at a temperature of 200°C for 1 hour after harvesting. After baking, they are taken out and ground into powder with a particle size of 30um.

[0025] Preparation of okra tender pod extract: select okra tender pods with no damaged skin, wash them with clean water, and boil them in a pressure cooker with a pressure of 0.18Mpa for 2 hours, where the mass ratio of water to okra tender pods is 1.5: 1; Filter the residue in the pressure cooker, and take the clear liquid to vacuum concentrate...

Embodiment 2

[0029] The present invention provides an okra capsule, the main components and mass percentages of which are: okra seed powder 12%, okra pollen 18%, okra extract 62%, and okra root powder 8%. The preparation process is:

[0030] Prepare okra seed powder: select mature okra seeds, wash with water, dry at 40°C, and stir-fry at 70°C for 2 hours, and grind the fried seeds into a powder with a particle size of 50um;

[0031] Preparation of okra pollen: Take okra flowers in the early morning, and directly bake them in an oven at a temperature of 100°C for 2 hours after harvesting. After baking, they are taken out and ground into powder with a particle size of 20um.

[0032] Preparation of okra tender pod extract: select okra tender pods with no damaged skin, wash them with clean water, and boil them in a pressure cooker with a pressure of 0.18Mpa for 2 hours. The mass ratio of water to okra tender pods is 1.5: 1; Filter the residue in the pressure cooker, and take the clear liquid to vacu...

Embodiment 3

[0036] The present invention provides an okra capsule, the main components and mass percentages of which are: okra seed powder 15%, okra pollen 10%, okra extract 70%, and okra root powder 10%. The preparation process is:

[0037] Preparation of okra seed powder: select mature okra seeds, wash with water, dry at 37°C, and stir-fry at 80°C for 1.5 hours, and grind the fried seeds into a powder with a particle size of 30um;

[0038] Prepare okra pollen: take okra flowers in the early morning, and directly bake them in an oven at a temperature of 150°C for 1.5 hours after harvesting. After baking, they are taken out and ground into powder with a particle size of 20um.

[0039] Preparation of okra tender pod extract: select okra tender pods with no damage to the epidermis, wash them with clean water, and place them in a pressure cooker with a pressure of 0.18Mpa to boil for 1.5 hours, where the mass ratio of water to okra tender pods is 1.5 :1; The residue in the pressure cooker is filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com