Frozen mousse cake and industrial preparation method thereof

A mousse cake and cake technology, applied in baking, baked goods, food science and other directions, can solve the problems of lower product quality, destruction of fat crystals, difficulty in sending, etc., and achieve high product stability, low fat content, and storage time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

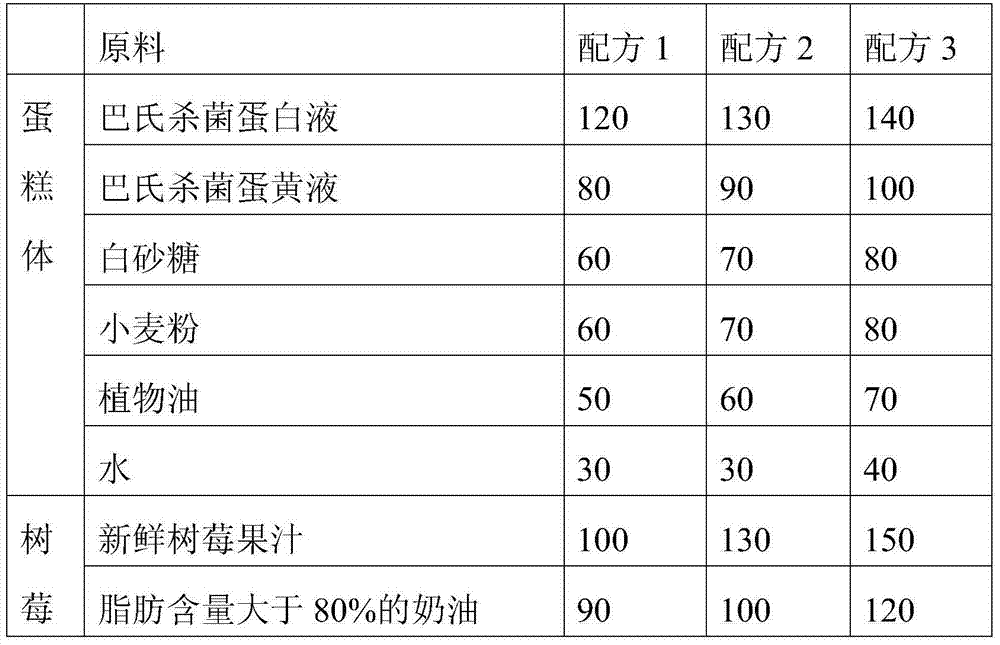

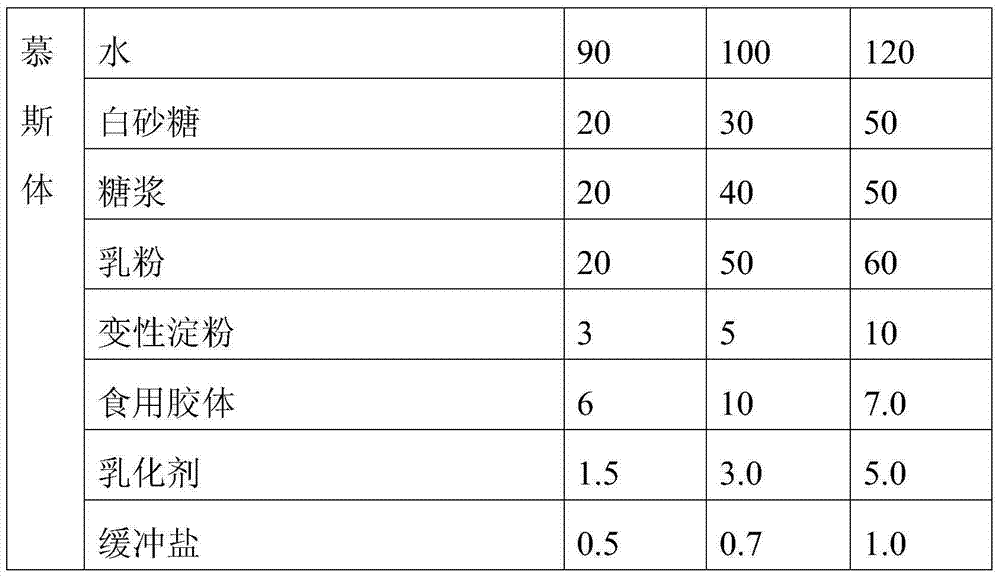

[0024] Specific embodiment one: frozen raspberry mousse cake and its preparation

[0025] Carry out the preparation of freezing raspberry mousse cake with following process according to formula described in following table 1, its main steps are as follows:

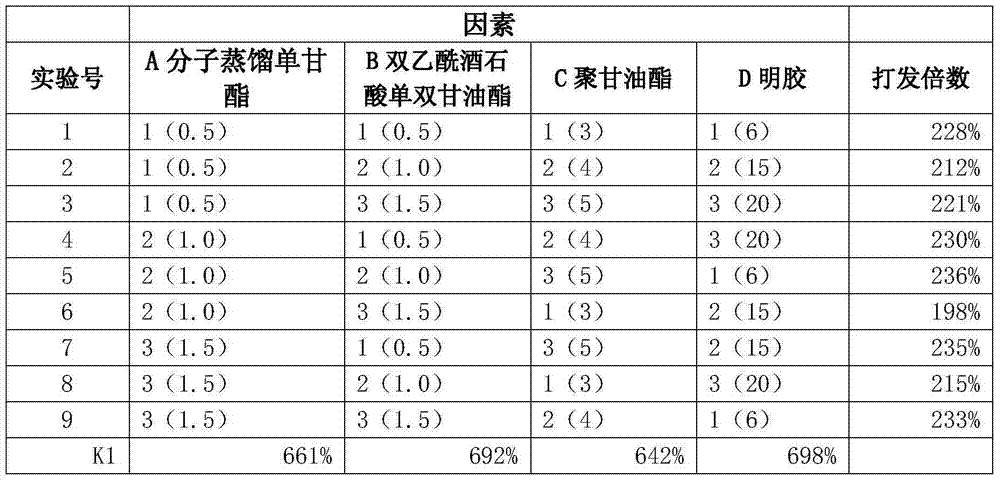

[0026] (1) Preparation of cake body: take the batter material of formula quantity, this batter material mainly comprises pasteurized egg yolk liquid, wheat flour, vegetable oil and water, after above-mentioned batter material is mixed evenly, obtain the batter that specific gravity is 0.35~0.45; Pasteurized protein liquid and white sugar are sent with an air-filled sender until the specific gravity of the protein reaches 0.25-0.30, and then the beaten protein is added to the batter and mixed evenly to obtain a cake batter. After baking for 15-20 minutes in a tunnel oven with a primer at 170±5°C and an upper fire at 180±5°C, cool at a constant temperature in a cooling room with a temperature of 16-20°C and a humidity of 60...

specific Embodiment 2

[0060] Specific embodiment two: frozen chocolate mousse cake and its preparation

[0061] Carry out the preparation of frozen chocolate mousse cake according to the recipe described in the following table 8 with the following process, and its main steps are as follows:

[0062] (1) Preparation of cake body: take the batter material of formula quantity, this batter material mainly comprises pasteurized egg yolk liquid, wheat flour, vegetable oil, water, chocolate, cocoa powder and syrup, after above-mentioned batter material is mixed, obtain specific gravity as 0.35-0.45 batter; use the pasteurized protein liquid and white sugar to send the pasteurized egg white machine until the specific gravity of the protein reaches 0.25-0.30, then add the beaten protein to the above batter and mix evenly to get the cake batter , place the cake batter in a tunnel oven and bake for 15-20 minutes with a primer at 170±5°C and an upper fire at 180±5°C, then keep the temperature in a cooling ro...

specific Embodiment 3

[0093] Specific embodiment three: frozen cream mousse cake and its preparation

[0094] Carry out the preparation of frozen cream mousse cake with the following process according to the formula described in the following table 15, and its main steps are as follows:

[0095] (1) Preparation of cake body: take the batter material of formula quantity, this batter material mainly comprises pasteurized egg yolk liquid, wheat flour, vegetable oil and water, after above-mentioned batter material is mixed evenly, obtain the batter that specific gravity is 0.35~0.45; Pasteurized protein liquid and white sugar are sent with an air-filled sender until the specific gravity of the protein reaches 0.25-0.30, and then the beaten protein is added to the batter and mixed evenly to obtain a cake batter. After baking for 15-20 minutes in a tunnel oven with a primer at 170±5°C and an upper fire at 180±5°C, cool at a constant temperature in a cooling room with a temperature of 16-20°C and a humi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com