Engine control valve with improved sealing

A technology for controlling valves and engines, applied in the directions of engine components, machines/engines, lift valves, etc., can solve problems such as obstructing valve operation mechanism, obstructing contact, etc., to achieve the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The engine control valve according to the invention may for example be an EGR (Exhaust Gas Recirculation) valve which regulates the gas flow in a circuit connecting the exhaust line to the intake line of the internal combustion engine of the vehicle.

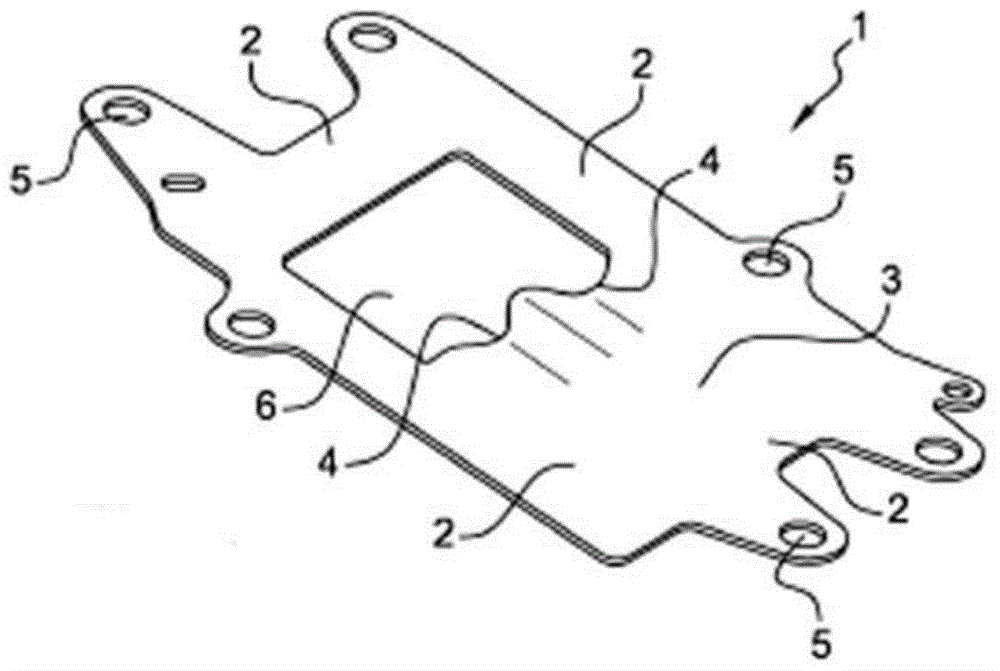

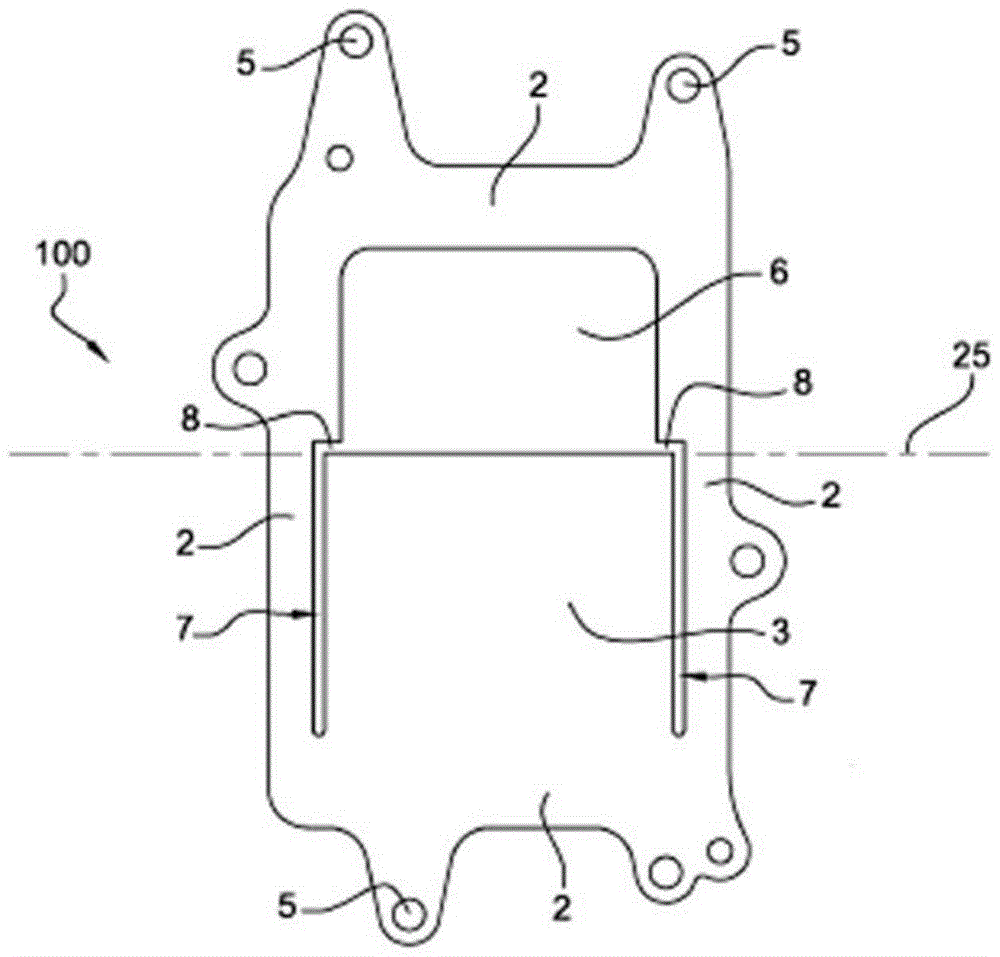

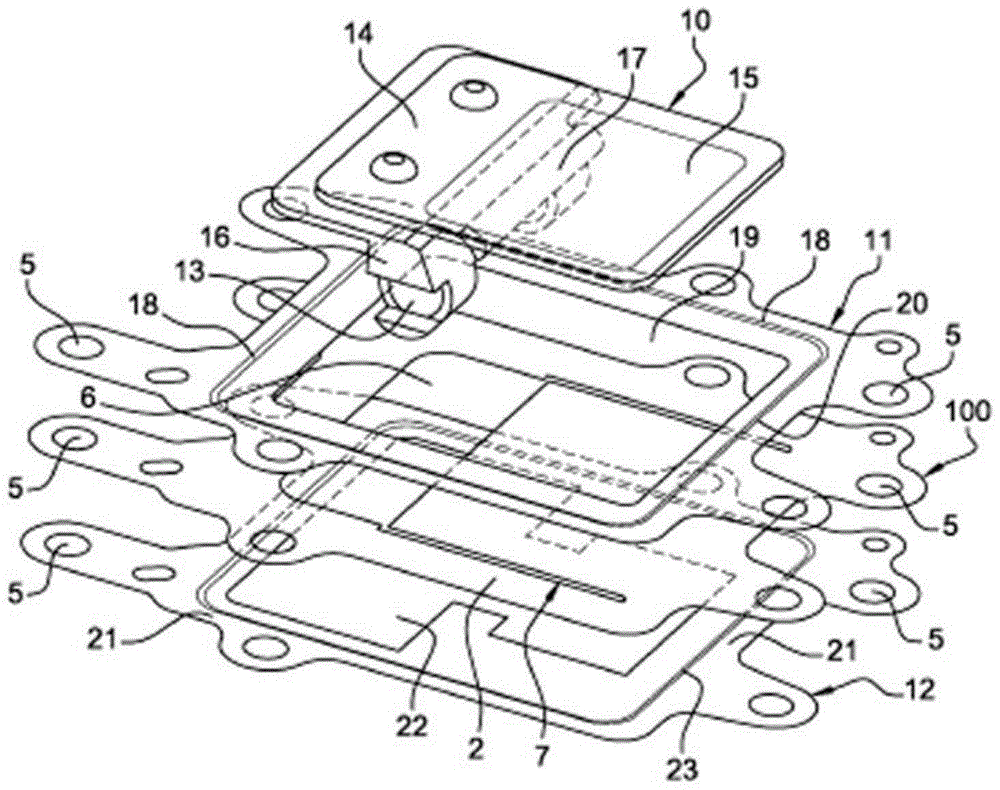

[0030] by reference figure 1 , the prior art seal 1 is made of rigid stainless steel and is inserted in the region of its peripheral region 2 between cast elements made of stainless steel of the body of said valve 1 . This peripheral area 2 thus comprises a certain number of holes 5 designed to be passed by the screws securing the seal 1 between said cast elements. Said seal 1 is flat, has a substantially rectangular shape and a small thickness, and has a solid part 3 outside a through-opening 6 for gas, said part 3 and said opening 6 forming said seal 1 central part of the . This opening 6 is rectangular and has been formed in the seal 1 such that its longitudinal axis is perpendicular to the longitudinal axis of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com