Digital-electronic ballast circuit of electromagnetic induction lamp

A technology of electromagnetic induction lamps and digital electronics, applied in electric light sources, electrical components, lighting devices, etc., can solve the problems of inconsistent lamp parameters, poor start of electromagnetic induction lamps, affecting the service life of lamps and couplers, etc. The effect of prolonging service life and solving communication problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

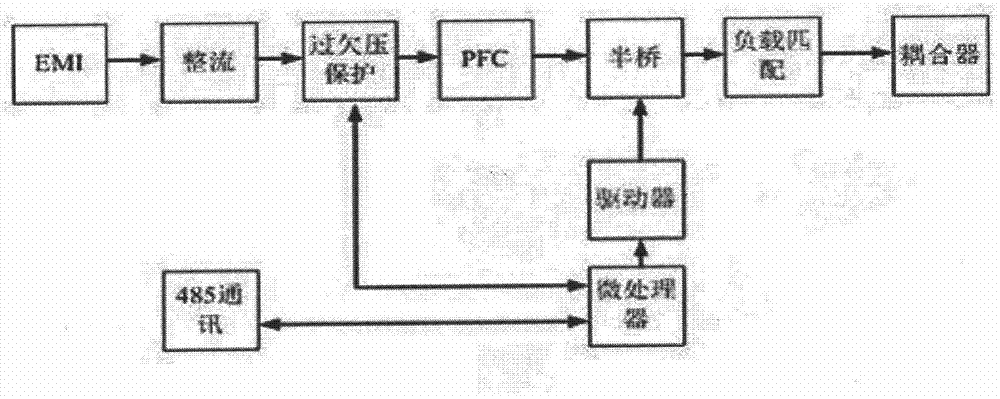

[0018] figure 1 The digital electronic ballast circuit for electromagnetic induction lamp shown is composed of rectification filter circuit, PFC power factor control circuit, half bridge drive circuit, load matching circuit, embedded microprocessor controller circuit, protection circuit, 485 communication circuit and corresponding software. .

[0019] The rectification and filtering circuit, the overvoltage and undervoltage protection circuit, the PFC power factor control circuit, the half-bridge drive circuit, and the load matching circuit are connected in sequence. The microprocessor is connected with the overvoltage and undervoltage protection circuit, the half-bridge drive circuit and the 485 communication circuit.

[0020] working principle:

[0021] The AC voltage is converted to DC voltage after EMI filtering (differential mode noise filtering, common mode noise filtering), rectification and capacitor filtering. The PFC power factor control circuit uses soft switchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com