Lever and supporting matching structure for circuit breaker operation mechanism

A technology of operating mechanism and matching structure, which is applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of difficult processing, increase processing cost, and affect the performance stability of the operating mechanism, so as to improve performance stability, service life, wear and tear small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

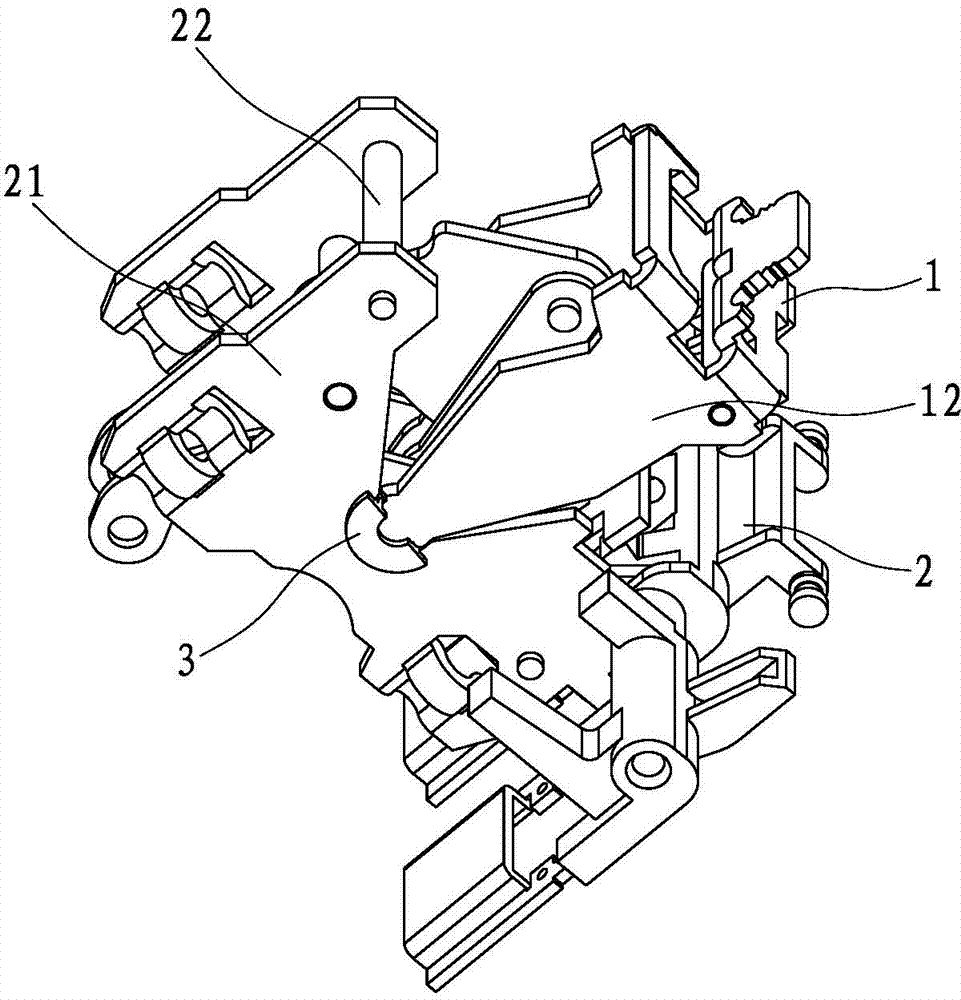

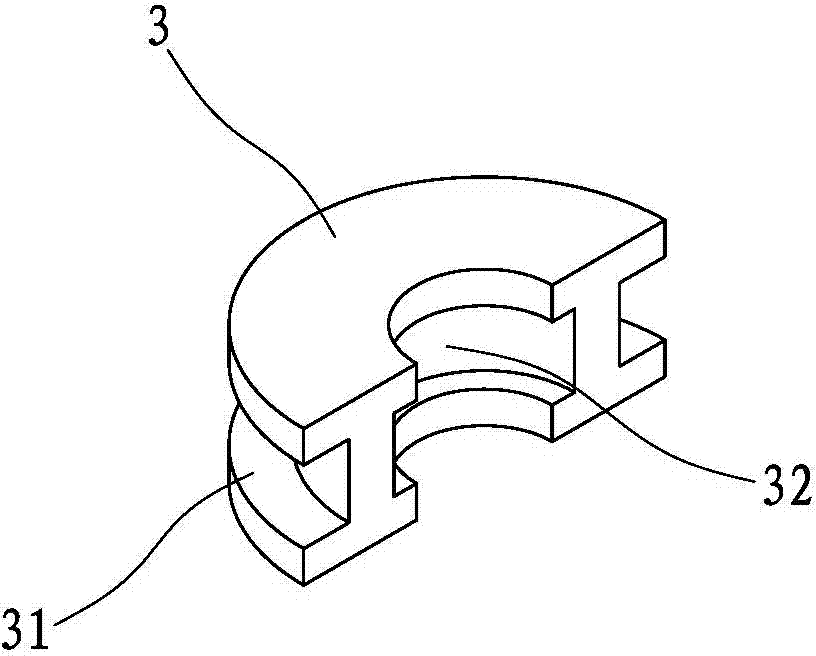

[0031] refer to Figure 1 to Figure 6 As shown, a lever and bracket cooperation structure of a circuit breaker operating mechanism includes a lever 1 , a bracket 2 and a wear-resistant positioning sleeve 3 .

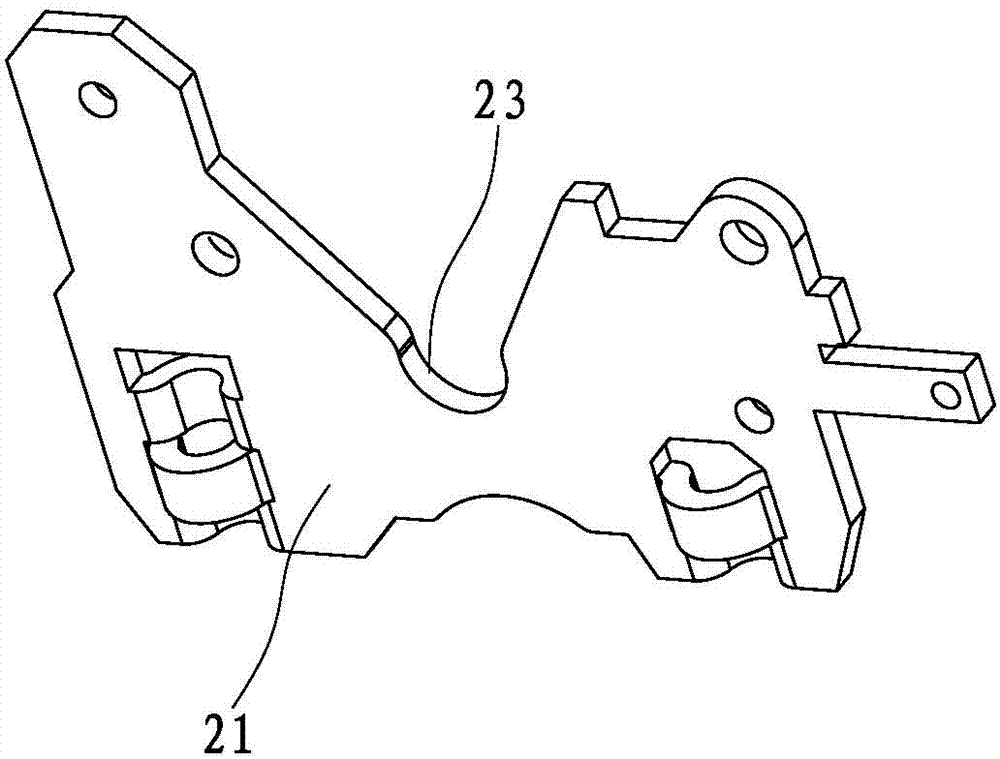

[0032] The bracket 2 includes two side plates 21 and connecting pieces 22 connecting the two side plates 21 , each side plate 21 is provided with a groove 23 for the lever 1 to be rotatably contacted.

[0033] The lever 1 includes a lever main body 11 and rotating feet 12 arranged on both sides of the lever main body 11 , and each rotating foot 12 is provided with a support foot 13 at a contact end in rotatable contact with the bracket 2 . The slot 23 is preferably set as an arc-shaped slot, and correspondingly, the supporting foot 13 is preferably set as an arc-shaped supporting foot. Of course, the groove 23 and the supporting foot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com