Micro-scanning platform, shooting method and work area flatness calibration method

A work area and scanning platform technology, applied in microscopes, optics, instruments, etc., can solve problems such as defocusing, rising costs, and increasing hardware complexity, and achieve the effects of reducing manufacturing costs, high scanning efficiency, and high scanning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

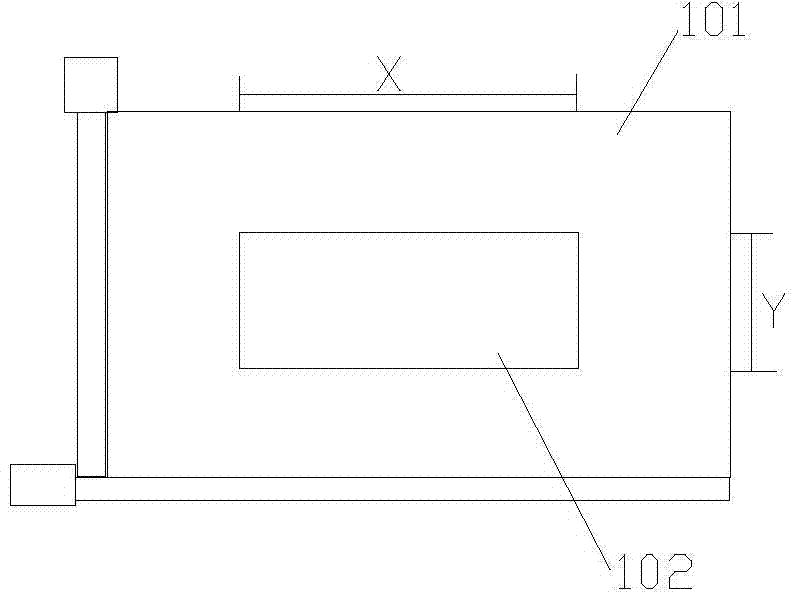

[0039]figure 1 The object table 101 and the working area 102 on the object table 101 are given in , and the slide glass is generally set in the working area. A light source is generally arranged below the working area 102 , and a lens is generally arranged above the working area 102 . The stage 101 can move along the plane defined by the X-axis and the Y-axis, and the working area 102 can also move correspondingly. The X-axis and Y-axis are established on the stage 101, and the Z-axis is perpendicular to the XY plane.

[0040] Introduce method of the present invention below:

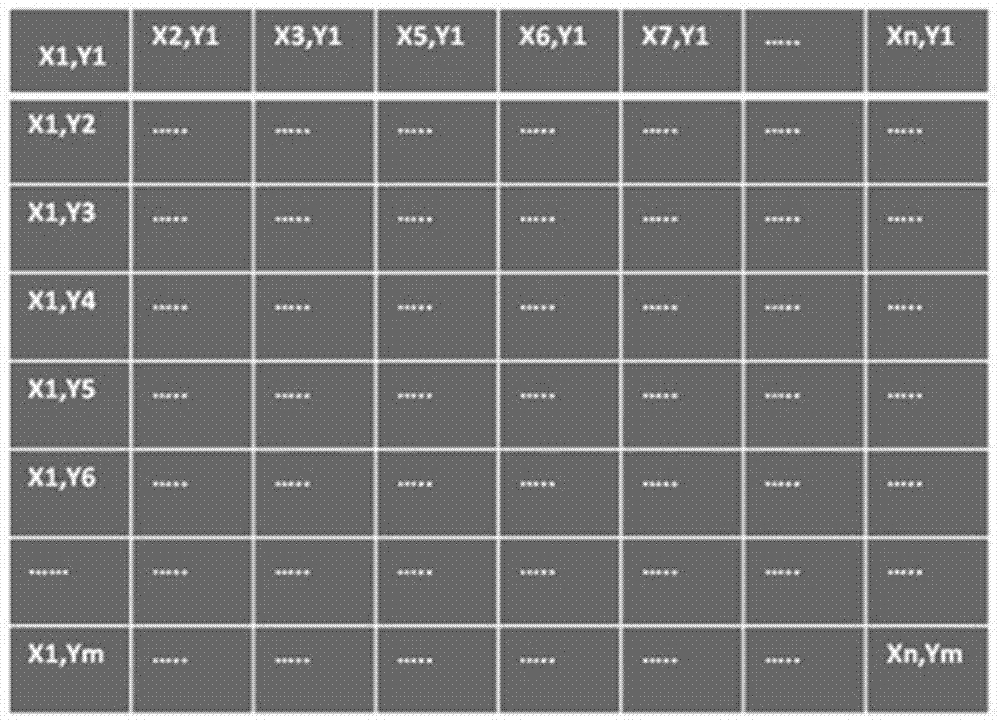

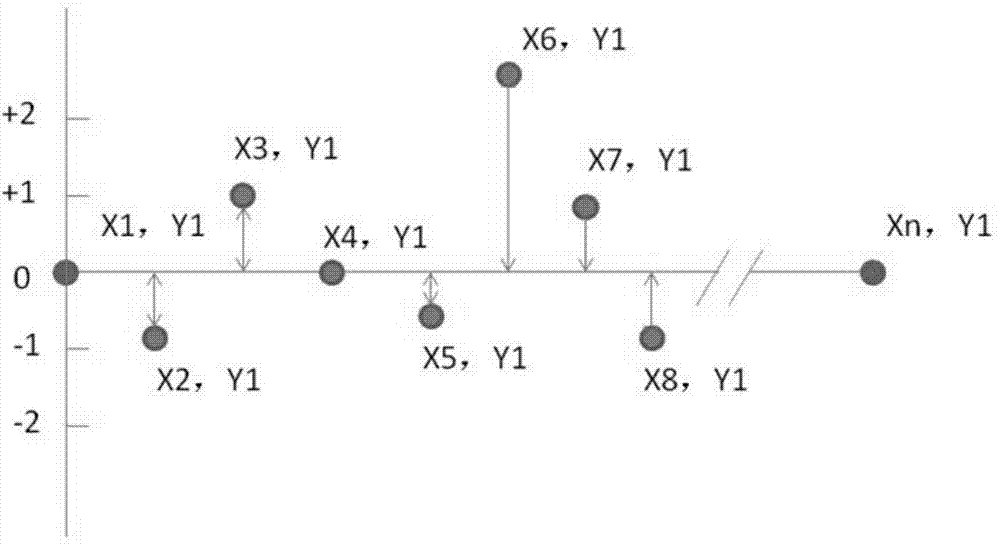

[0041] A. Divide the working area 102 of the stage 101 into n scanning points along the X-axis and the Y-axis to form a scanning coordinate system Sn(x, y), such as figure 2 As shown, each scan point corresponds to a coordinate, such as S1(x1,y1), S2(x2,y1) and so on....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com