Method for monitoring destroying depth of mining working face base plate in real time

A damage depth, real-time monitoring technology, applied in the direction of measurement, earthwork drilling, electrical/magnetic detection for logging records, etc., can solve the problems of bottom plate depth damage value deviation, long working cycle, hysteresis, etc., to achieve The effect of simple monitoring process, accurate measurement data and short working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The present invention will be further described below by way of embodiments and in conjunction with the accompanying drawings.

[0020] Example:

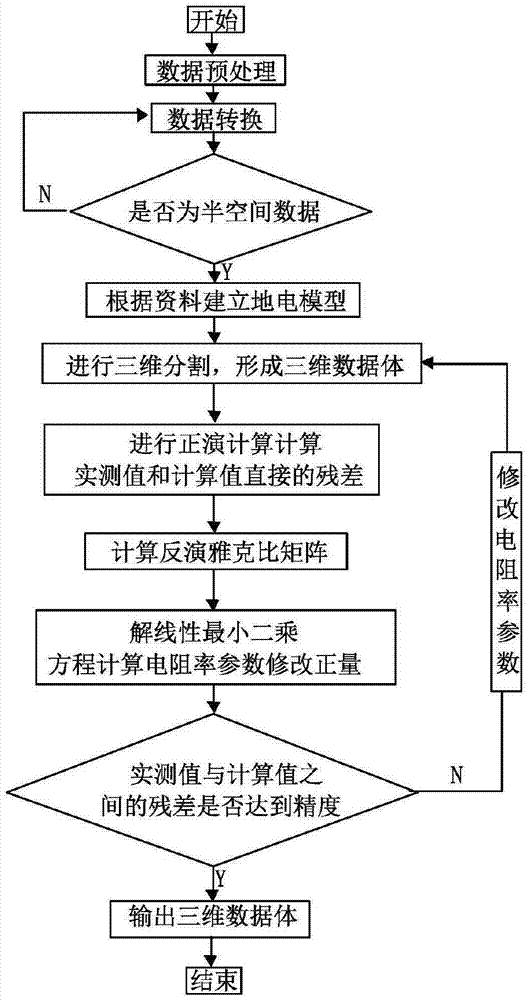

[0021] In this embodiment, the specific process of realizing the real-time monitoring of the damage depth of the bottom plate of the working face is as follows:

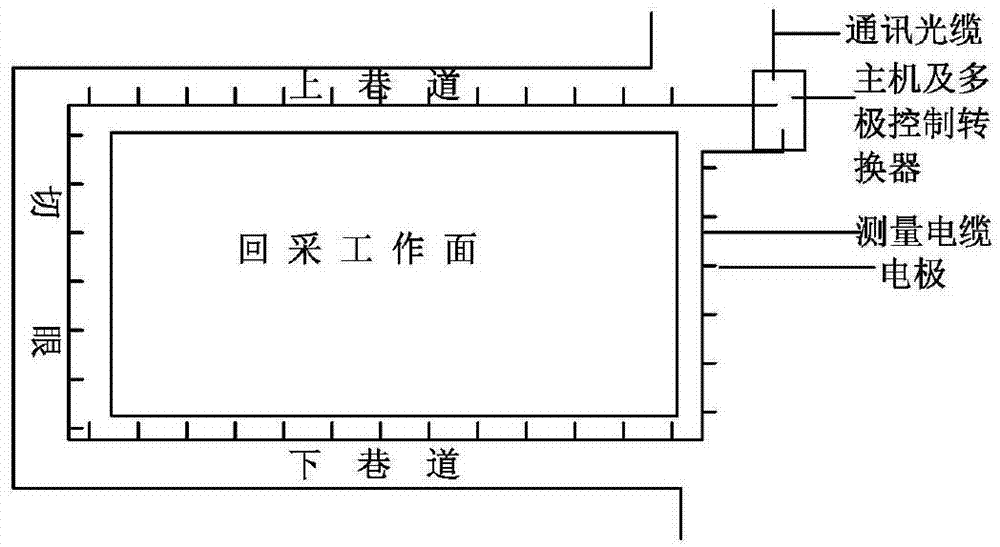

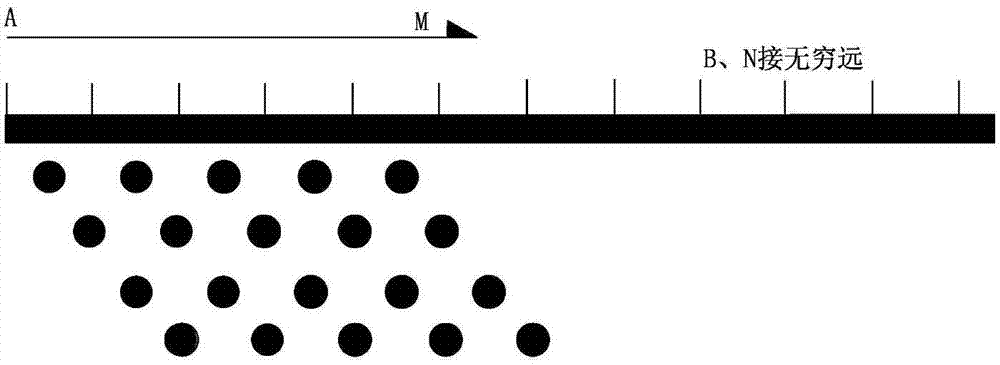

[0022] (1) The downhole observation system is used for data collection. The downhole observation system is as follows: figure 1 As shown, first connect the measuring cable to the electrodes, the distance between adjacent electrodes is 10m (the distance between the electrodes can be set according to the requirements), and bury the connected measuring cables and electrodes 0.5m below the bottom plate of the working face at one time to prevent mining The fall of the rock mass in the empty area will damage the cable and surround the working face for a week, then connect the resistivity measurement and control host with the multi-pole control converter through the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com