CH4169 alloy forging piece grain size analysis and predication method

A technology of GH4169 and prediction method, which is applied in the field of high-temperature alloy forging, can solve the problems of small sample size, etc., and achieve the effect of convenient use and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Analyze and predict the grain size of the GH4169 alloy five-stage plate and the die forgings obtained on the SPKA22400 screw press;

[0032] The first step, compression test of GH4169 alloy double cone specimen

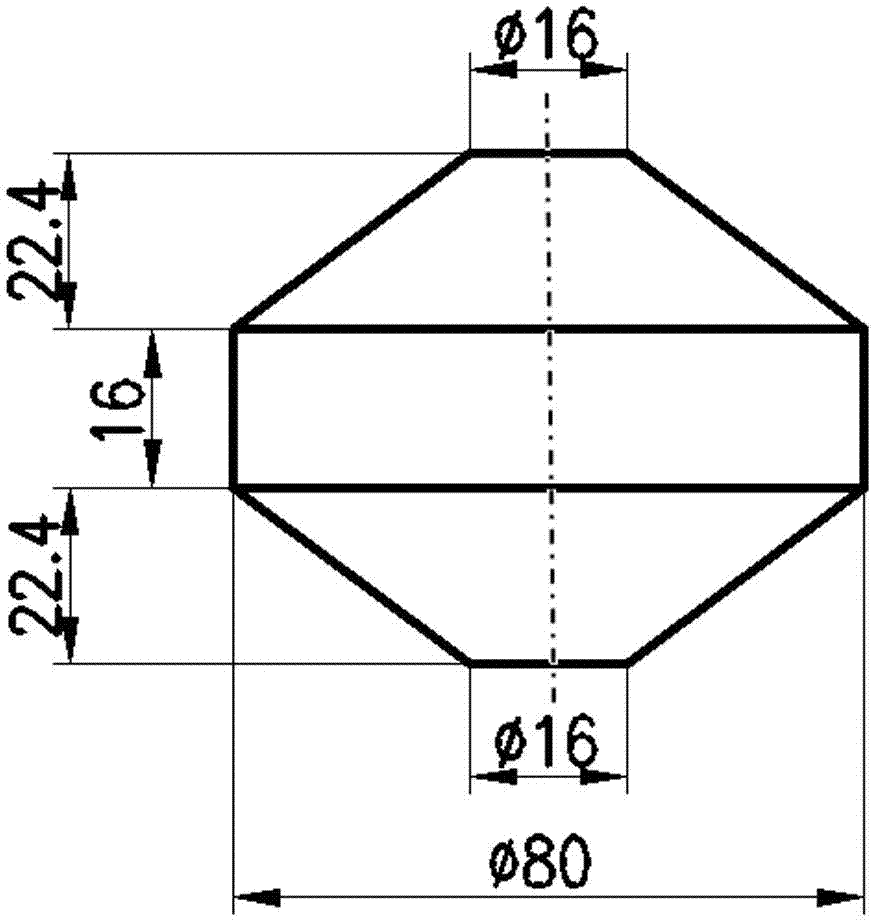

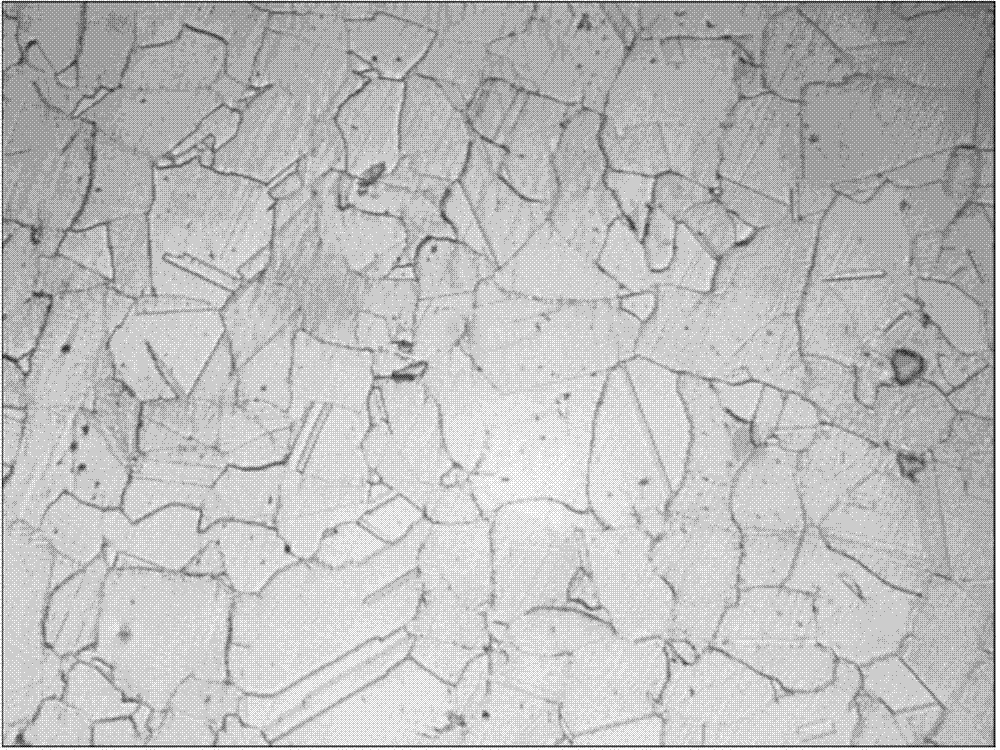

[0033] Adopt attached figure 1 The GH4169 alloy double cone sample shown is between the upper and lower anvils of the screw press for a near isothermal forging compression test. The original grain size of the GH4169 alloy double cone sample is grade 5. figure 2 . The main parameters of the test include: the heating temperature of the upper and lower anvils is 900℃; the heating temperature of the GH4169 alloy double cone sample is 930℃, 960℃, 990℃, 1010℃ and 1040℃; the maximum deformation degree of the GH4169 alloy double cone sample is 60%; After the deformation, the sample is quickly placed in a water tank for water cooling treatment, with image 3 It is a schematic diagram of the round cake after compression.

[0034] The second step is the finite element simu...

Embodiment 2

[0050] Analyze and predict the grain size of the die forgings obtained on the GH4169 alloy grade 5-8 disc SPKA22400 screw press;

[0051] The first step, GH4169 alloy double cone compression test

[0052] Adopt attached figure 1 The GH4169 alloy double cone sample shown is between the upper and lower anvils of the screw press for a near isothermal forging compression test. The original grain size of the GH4169 alloy double cone is grade 5. figure 2 . The main parameters of the test include: the heating temperature of the upper and lower anvils is 900℃; the heating temperature of the GH4169 alloy double cone sample is 930℃, 960℃, 990℃, 1010℃ and 1040℃; the maximum deformation degree of the GH4169 alloy double cone sample is 60%; After the deformation, the sample is quickly placed in a water tank for water cooling treatment, with image 3 It is a schematic diagram of the round cake after compression.

[0053] The second step, finite element simulation of GH4169 alloy double cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com