A heavy-duty truss

A technology of truss and bottom beam, applied in the field of support frame, can solve the problems of inability to move the truss, low support weight, lack of guiding function, etc., and achieve the effect of moving the propulsion device quickly and accurately, meeting the needs of precise positioning, and moving the product conveniently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

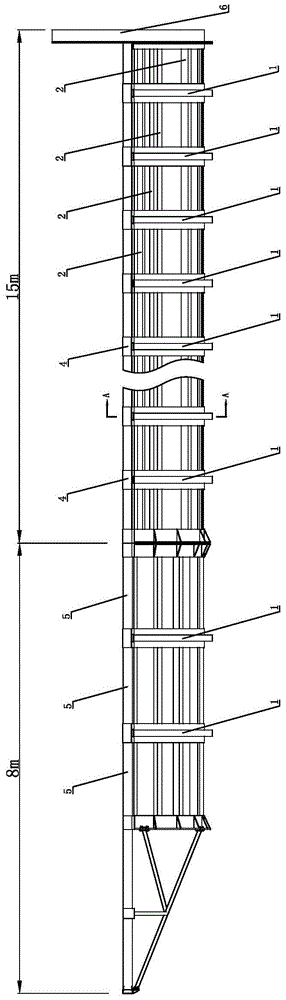

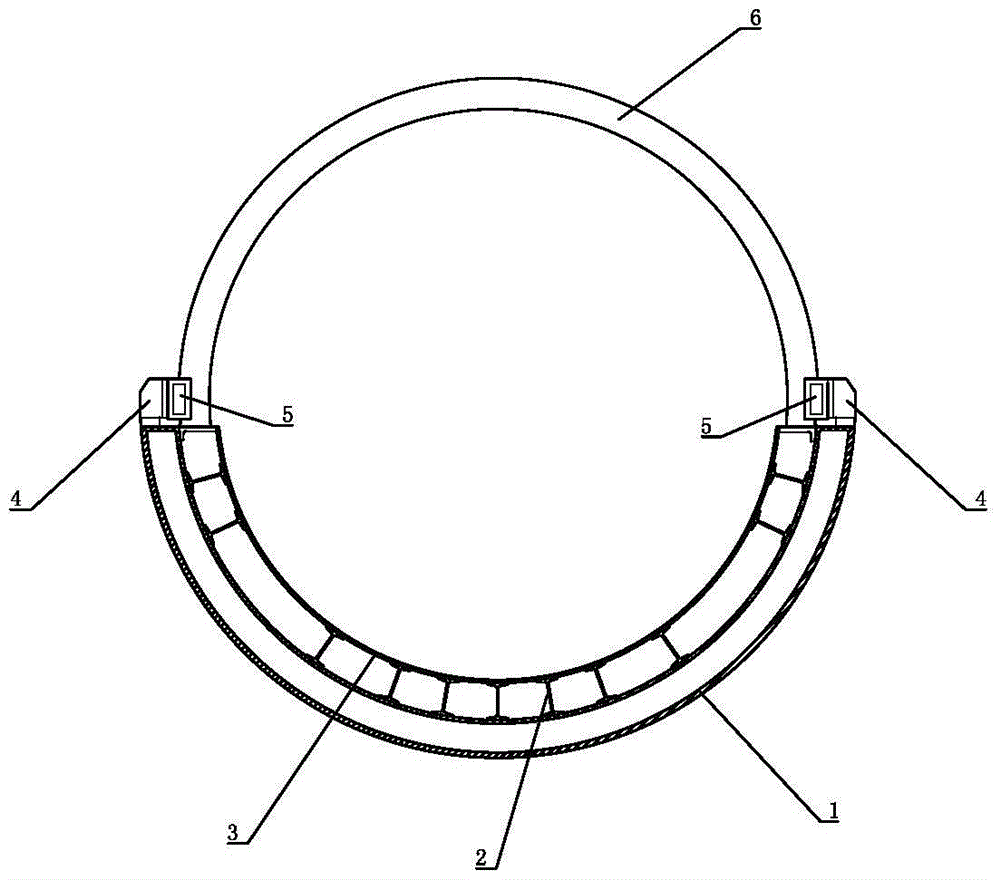

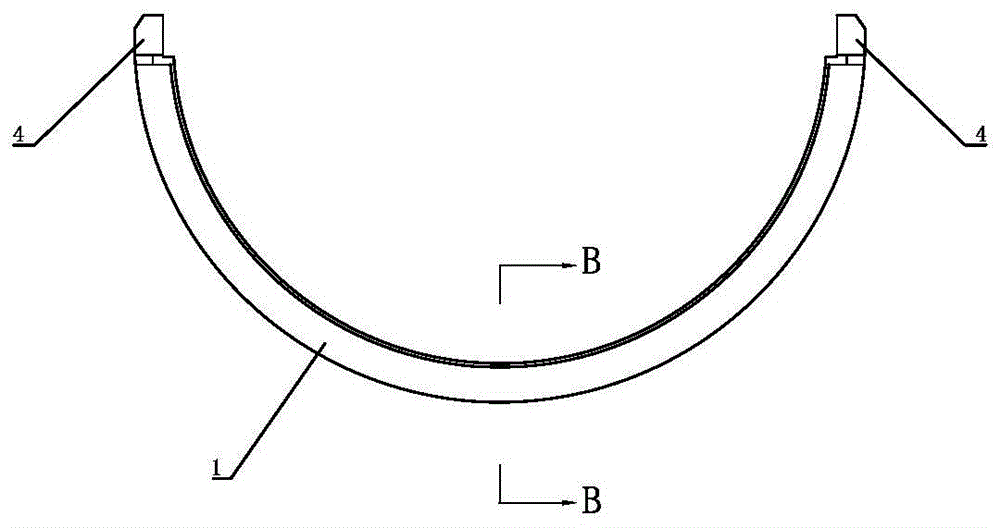

[0021] Such as Figure 1 to Figure 6 In the schematic diagram of a specific embodiment of a heavy-duty truss shown in the present invention, it includes multiple groups of bottom beams 1, multiple beams 2 and skins 3, the bottom beams 1 are semi-circular and their openings are upward, so that multiple groups of bottom beams 1. Distribute them along the horizontal direction and make them parallel to each other, so that the centers of the semicircular rings of multiple groups of bottom beams 1 are on the same horizontal line. A plurality of crossbeams 2 are fixed horizontally inside the bottom beam 1 and distributed along the circumference of the semicircle, and a long skin 3 is laid on the crossbeams 2 . This structural design fully combines the shape of the supporting product. When the supporting product is moving on the truss, it is subject to both radial constraint and axial guidance, making it more convenient, fast and accurate to move the product.

[0022] In order to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com