A rotating platform mechanism for detecting cables

A technology for rotating platforms and cables, used in measuring devices, bridge parts, erecting/assembling bridges, etc., can solve the problems of backward inspection and maintenance methods of oblique cables, cumbersomeness, and high energy consumption, so as to improve detection accuracy and range of motion. Large, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

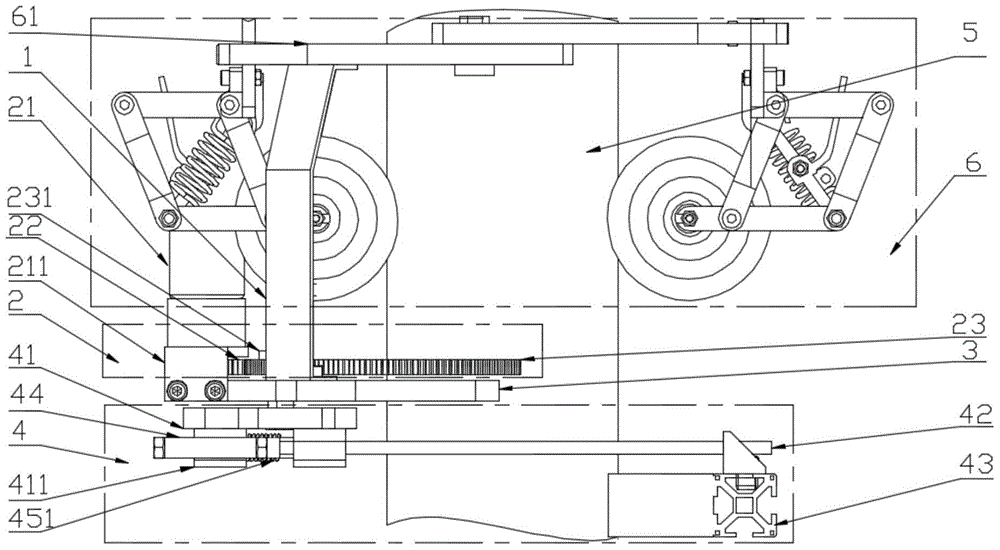

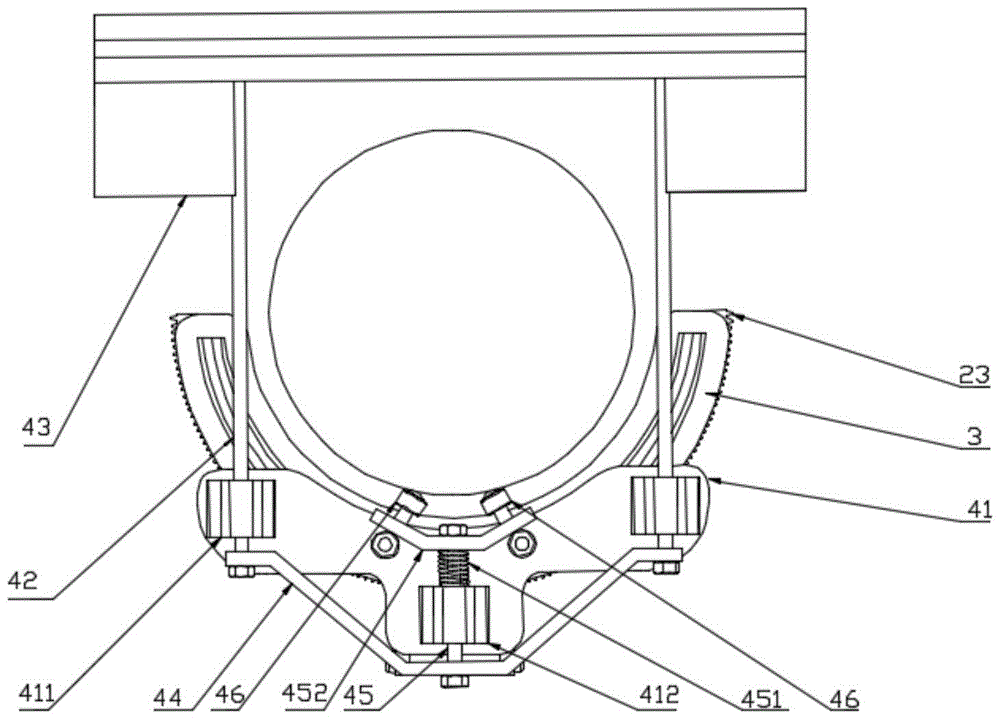

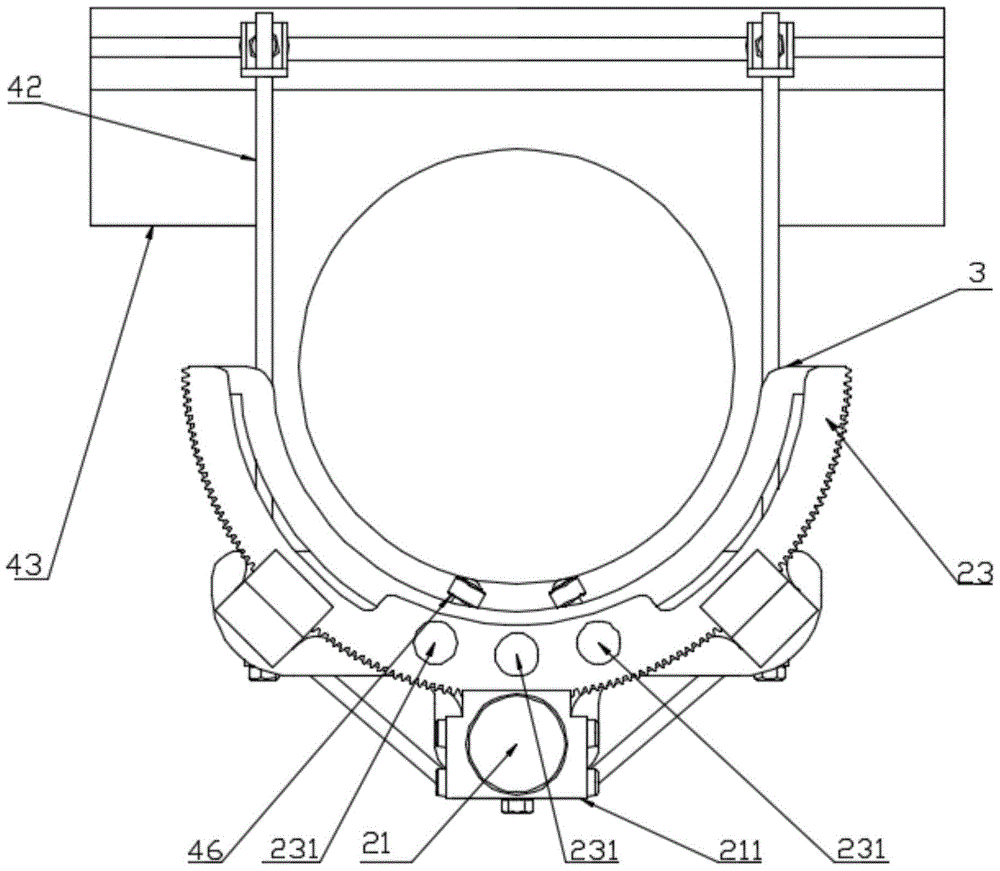

[0037] like Figure 1 to Figure 5 As shown, a rotating platform mechanism for detecting cables includes a connecting rib 1 , a positioning member fixedly connected to the connecting rib 1 , and a driving device 2 and a measuring device 4 connected to the positioning member. The positioning member is a guide rail 3 , the driving device 2 is located above the guide rail 3 , and the measuring device 4 is located below the guide rail 3 .

[0038] Drive device 2 comprises motor support base 211, reduction motor 21, first gear 22 and second gear 23; Motor support base 211 is fixedly connected with guide rail 3, and reduction motor 21 is fixedly connected on the motor support base 211, and first gear 22 passes through The bearing is fixedly connected on the motor support base 211, the first gear 22 cooperates with the output shaft of the reduction motor 21, and the first gear 22 meshes with the second gear 23; the second gear 23 is arc-shaped.

[0039] The measurement device 4 inclu...

Embodiment 2

[0045] like Image 6 and Figure 7 As shown, a cable-based rotary platform mechanism includes a connecting rib 1 , a positioning member fixedly connected to the connecting rib 1 , and a driving device 2 and a measuring device 4 connected to the positioning member. The positioning member is a guide rail 3 , the driving device 2 is located above the guide rail 3 , and the measuring device 4 is located below the guide rail 3 .

[0046] The driving device 2 includes a geared motor 21, a first connecting rod 24, a second connecting rod 25 and a slide block 26; the geared motor 21 is fixedly connected to the guide rail 3, and one end of the first connecting rod 24 is fixedly connected to the output shaft of the geared motor 21 Above, the other end of the first connecting rod 24 is connected to one end of the second connecting rod 25 by a sliding bolt, and the other end of the second connecting rod 25 is connected to the slider 26 by a second sliding bolt 261, and the slider 26 is a...

Embodiment 3

[0052] like Figure 8 and Figure 9 As shown, a cable-based rotary platform mechanism includes a connecting rib 1 , a positioning member fixedly connected to the connecting rib 1 , and a driving device 2 and a measuring device 4 connected to the positioning member. The positioning member includes an adjustable connecting member 31 , a first connecting plate 481 and a second connecting plate 482 . The first connecting plate 481 and the second connecting plate 482 are fixedly connected to two ends of the adjustable connecting member 31 .

[0053] The structure of the adjustable connecting piece 31 can be various. by Figure 9 For example, there are two adjustable connecting pieces 31 . Each adjustable connecting piece 31 is provided with a row of parallel slotted holes, and the slotted holes of the two adjustable connecting pieces 31 are aligned and fixedly connected with positioning bolts. The adjustment of the cable radius by the rotating platform can be realized through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com