Forklift weighing device and automatic weighing method for forklift

A weighing device and automatic weighing technology, which is applied in the field of forklift weighing devices and forklift automatic weighing, can solve problems such as difficult to control the influence of cargo output signals, unguaranteed oil cylinder seals, and limited versatility, and achieve great promotion value. The effect of low cost, strong resistance to vibration and interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

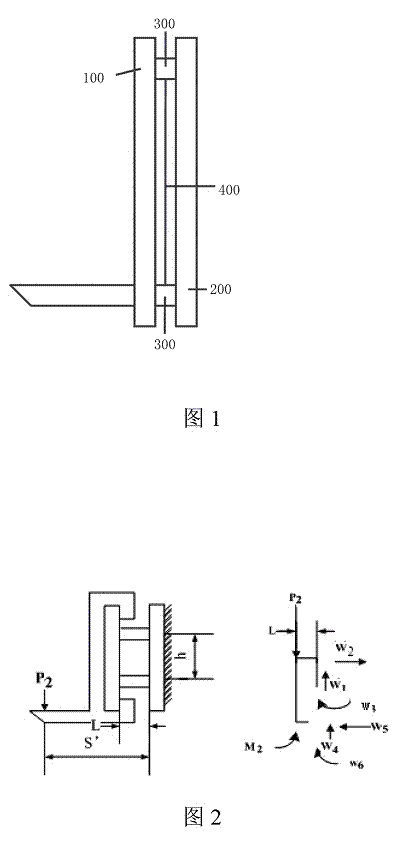

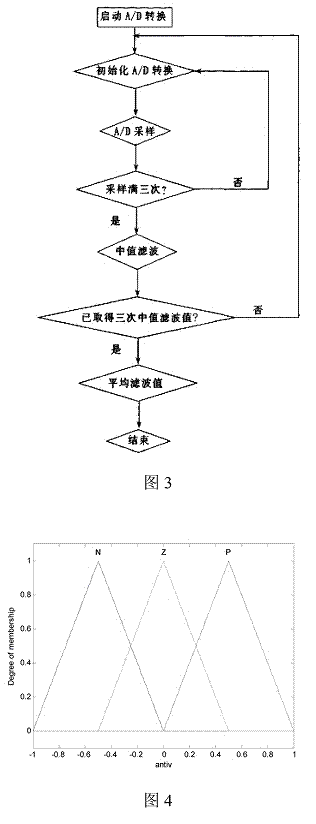

[0031] As shown in Fig. 1, a kind of forklift weighing device comprises double-fork hanging plate 100, forklift mast hanging plate 200 and two load cells 300 (resistance strain type pressure sensors in this embodiment), the two The load cell 300 is rigidly fixed by the fixing rod 400 and fastened between the double-fork hanging plate 100 and the forklift mast hanging plate 200, one of the sensors is directly above the other sensor, and the base hanging plate of the sensor 300 has sufficient rigidity , the amount of deformation under load is neglected, and the front and rear hanging plates have sufficient pre-tightened connections, which can be regarded as a rigid whole. At this time, the external force state of the load cell 300 is a three-time super-statically indeterminate problem. For the convenience of solving the problem, according to the condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com