Assembly for aircraft, and aircraft

A technology for aircraft and components, applied in the field of aircraft, engine installation, and commercial aircraft, can solve problems such as increased clearance, rotor wear at the tip of the blade, and reduced engine life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

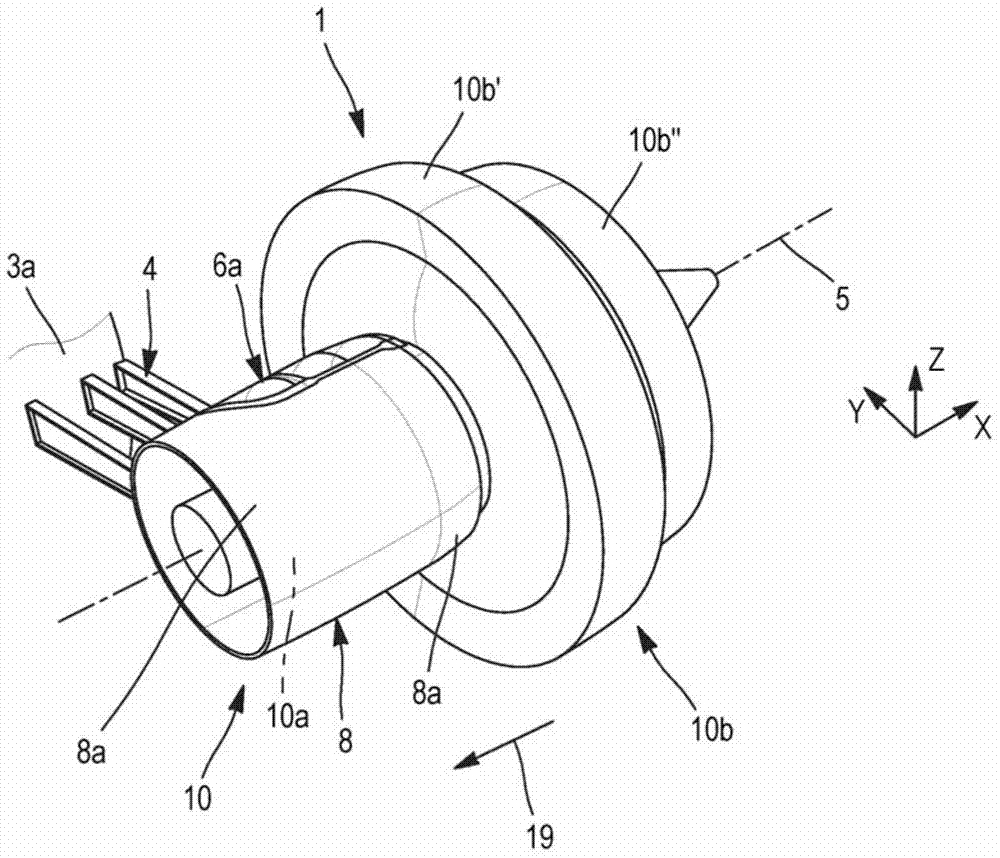

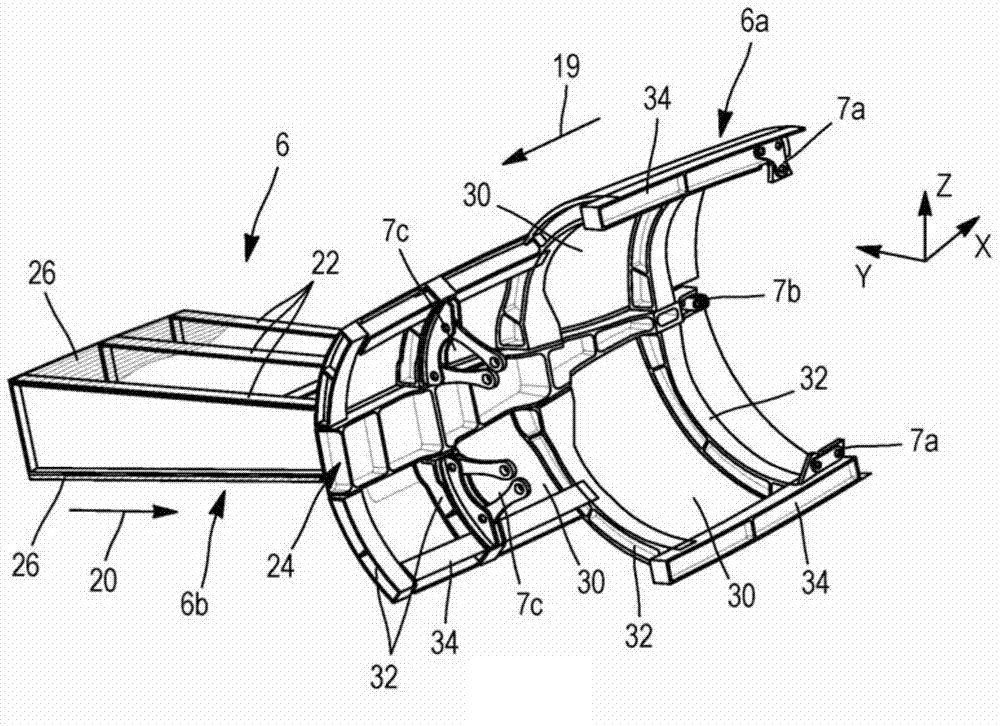

[0038] Refer to attached figure 1 , the attached figure 1 An aircraft 200 is depicted comprising a wing 2 fixed to a fuselage 3 at the rear of which an assembly 1 according to the invention is arranged. The assembly 1 comprises a rear section 3a of the fuselage, an engine 10 and mounting struts 4 for mounting the engine 10 on the rear section 3a of the fuselage. It should be noted that within the assembly 1 two engines 10 are each arranged on one side of the rear fuselage section 3 a respectively. However, in the remainder of the description, only the interaction between one of the two engines 10 and the rear fuselage section 3a will be described.

[0039] figure 2 Component 1 is depicted in enlarged form.

[0040] As mentioned above, this assembly 1 comprises the rear section 3a of the fuselage, the engine 10, the compartment 8 surrounding the engine, and the mounting struts 4 for mounting the engine 10 on the rear section 3a of the fuselage. The engine 10 is here prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com