Dual-motor drive-by-wire pressure sequence adjusting brake system

A brake system and dual-motor drive technology, applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of multi-arrangement space, increase system cost, and insufficient compact structure, and achieve simplified pressure regulation units and reduced Effect of small braking distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

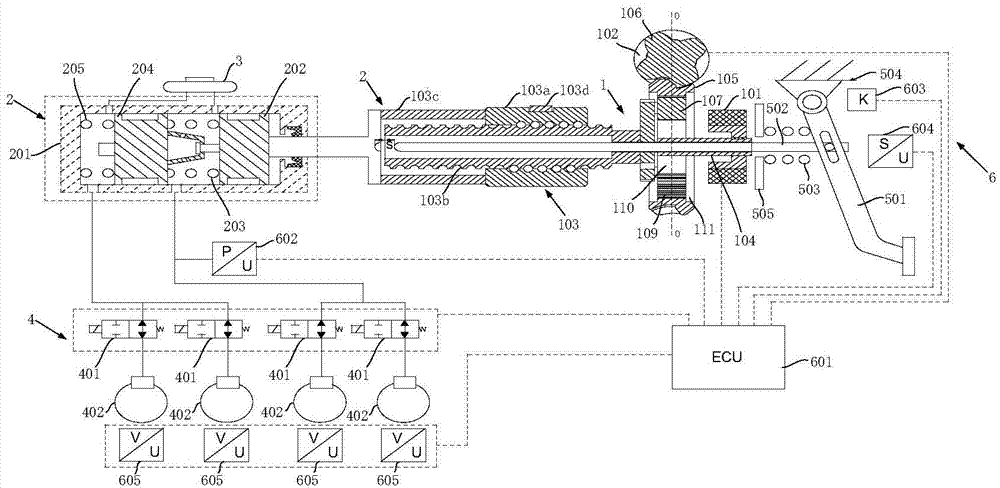

[0037] The pressure sequence adjustment braking system of the double motor line control of the present invention, such as figure 1 As shown, it includes a dual-motor drive transmission mechanism 1, a brake master cylinder 2, a liquid storage tank 3, a hydraulic adjustment system 4, a pedal mechanism 5 and an electronic control system 6, such as figure 1 shown.

[0038] The dual-motor drive transmission mechanism 1 includes a first motor 101, a second motor 102, a ball screw pair 103, a sun gear shaft 104, and a turbine 105, a worm 106, a planetary gear A107, a planetary gear B108, a planetary gear C109, and a sun gear. Wheel 110 and planetary carrier 111 form the transmission train.

[0039] Wherein, the first motor 101 adopts a hollow motor, has a motor rotor and a motor stator; the rotor of the first motor 101 is sleeved on the rear end of the sun gear sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com