DLP three-dimensional printer and three-dimensional printing method

A 3D printer and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of fast scanning speed, shape and size of light spots, and space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] DLP three-dimensional printer and first embodiment of three-dimensional printing method

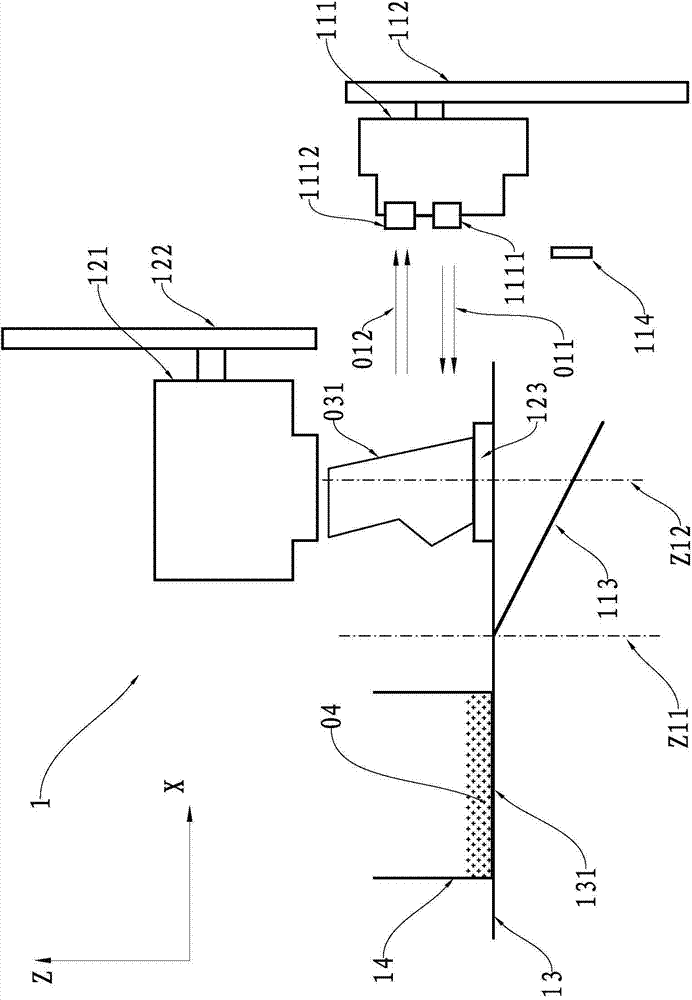

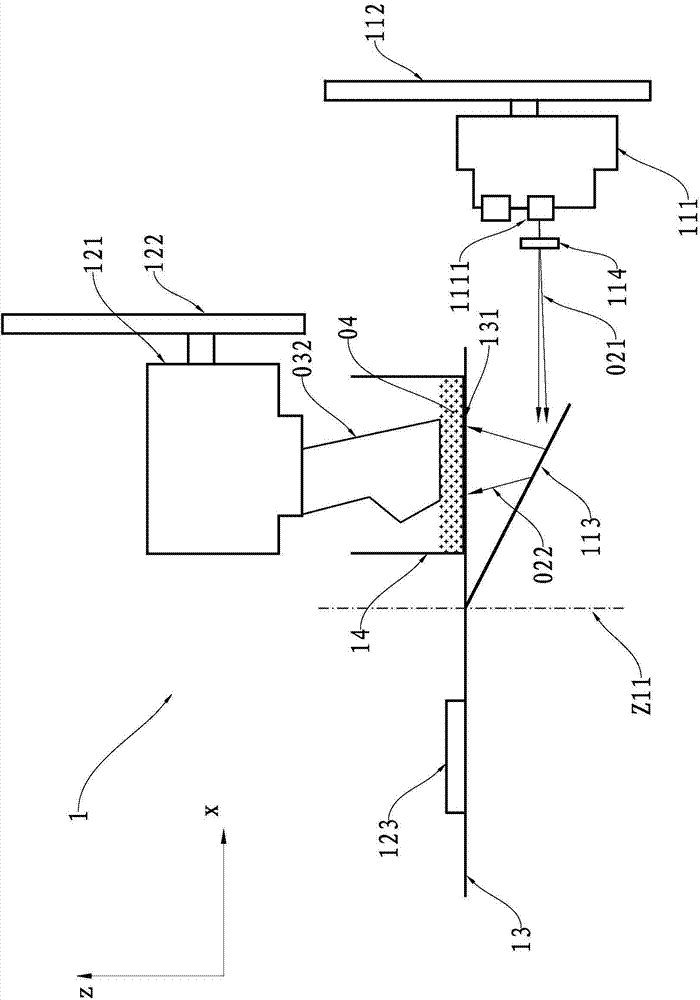

[0034] see figure 1The DLP three-dimensional printer 1 is composed of a frame, a control unit mounted on the frame, a scanning projection unit, a scanning and forming loading unit, a carrying table 13 and a forming tank 14 . The scanning projection unit is composed of a scanning projection device 111, a first lifting device 112, a light reflector 113, and a projection lens 114. The scanning projection device 111 is driven by the first lifting device 112 to move in the Z-axis direction relative to the carrier table 13; The loading unit is composed of a forming stage 121, a second elevating device 122 and a scanning object stage 123. The forming object stage 121 is driven by the second elevating device 122 to move in the Z-axis direction relative to the carrying platform 13; The table is arranged along the horizontal X-Y plane, and the relative frame can rotate around the rotation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com