High-flexibility deburring machine

A deburring machine, highly flexible technology, applied in the direction of grinding machine parts, machine tools suitable for grinding workpiece edges, metal processing equipment, etc. Complexity and other problems, to achieve the effect of reducing equipment cost, improving resource utilization efficiency, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

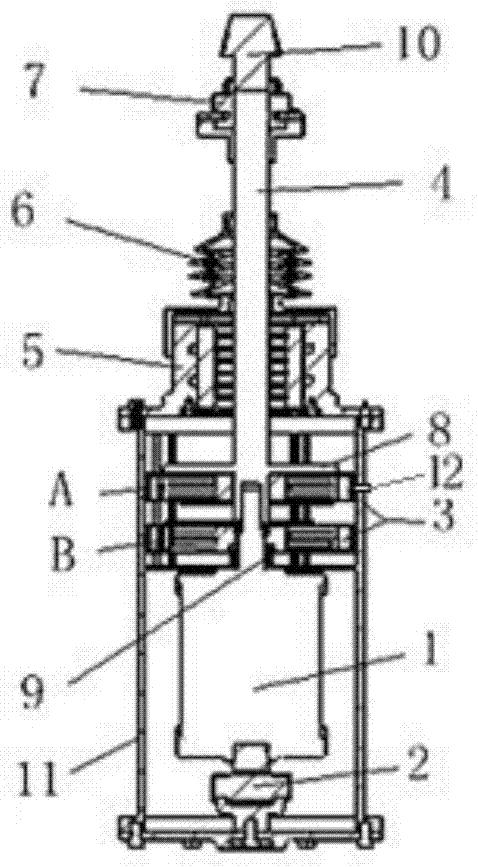

[0015] Such as figure 1 As shown, the present invention includes a motor 1, an axial buffer coil 3, a rotating shaft 4, an electromagnetic bearing 5 and a casing 11; the motor 1 and the axial buffer coil 3 are located in the casing 11, and the axial buffer coil 3 is composed of A Composed of two parts, A coil and the motor 1 are guaranteed through the bearing sleeve 9, and the farthest distance between the B coil and the A coil is constrained by the fixed circular plate 8 on the rotating shaft 4; the electromagnetic bearing 5 is located on the machine The outside of the casing 11 is fixedly connected to the casing 11; one end of the motor 1 is connected to the universal joint 2, the universal joint 2 is fixedly connected to the casing 11, the motor 1 is connected to the rotating shaft 4 through a spline, and the rotating shaft 4 is connected through a torque-limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com