Preparation method of TiO2/ZnFe2O4/active carbon composite material

A composite material, znfe2o4 technology, applied in the field of TiO2/ZnFe2O4/activated carbon (AC) composite material preparation, can solve problems such as preparation difficulties, and achieve the effect of improving photocatalytic degradation effect, promoting mineralization, and good visible light responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

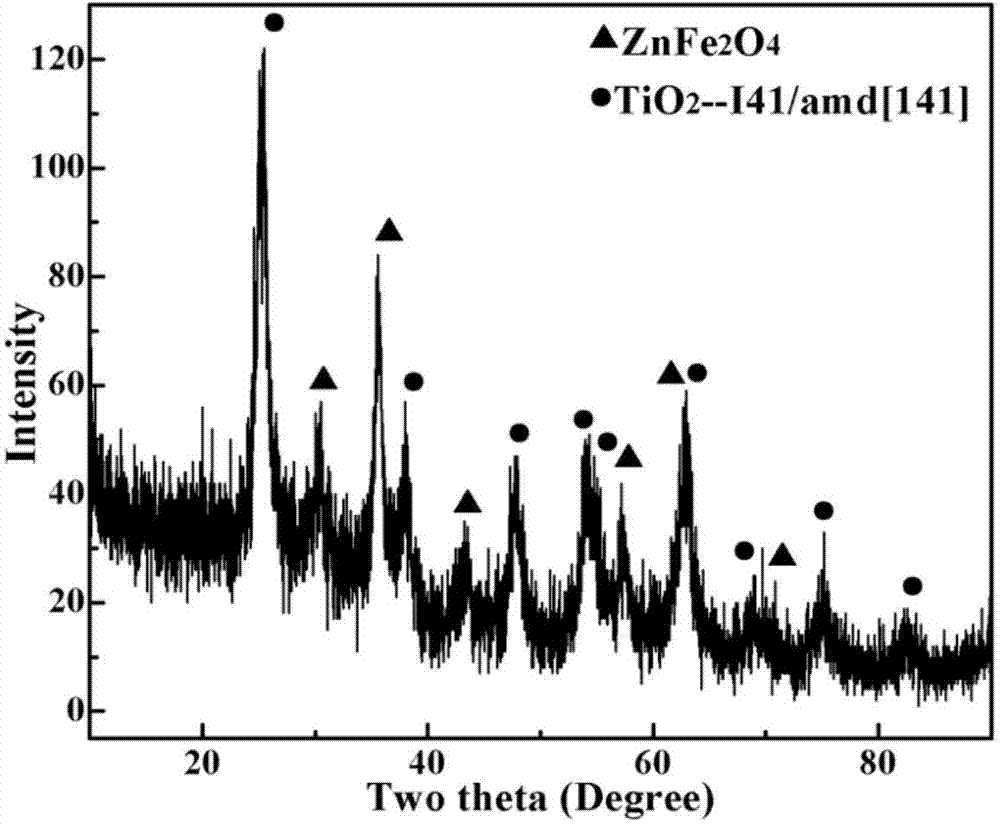

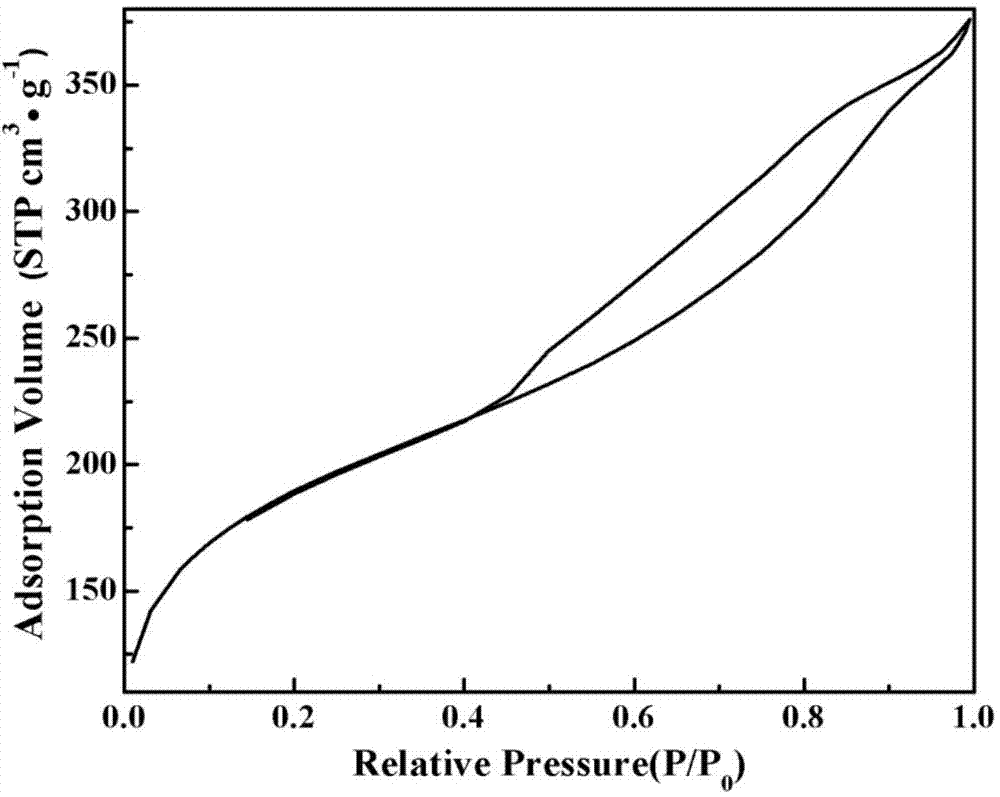

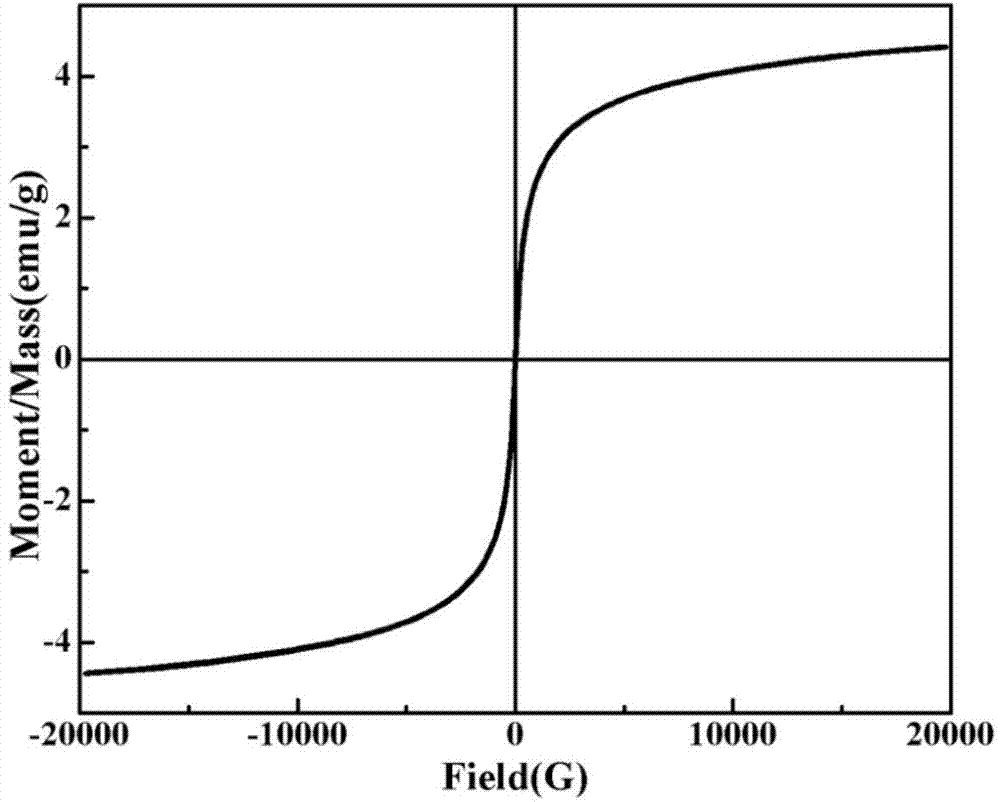

[0015] Specific embodiment 1: 3 mmol ZnCl 2 , 6 mmol FeCl 3 Add 6H2O and 1.8g AC to 70 ml of ethylene glycol, stir evenly with magnetic force, add 7.94 g of anhydrous sodium acetate, stir well, put it into a polytetrafluoroethylene-lined autoclave, and put it into a constant temperature drum Insulated in an air drying oven at 190 °C for 14 h. After cooling, use magnetic separation to separate the black product, wash it with deionized water and absolute ethanol until it is neutral, and then dry it at 80°C for 6 hours to obtain ZnFe 2 o 4 / AC Composite. Sol-Gel Synthesis of TiO 2 / ZnFe 2 o 4 / AC composite material: under stirring, 1 ml of butyl titanate was added dropwise into 20 ml of absolute ethanol to prepare solution A. Mix 1 ml of anhydrous acetic acid, 1 ml of deionized water and 10 ml of absolute ethanol to prepare solution B. Under the condition of stirring, add solution B dropwise to solution A, after stirring for 1 h to obtain a transparent and clear sol, add...

specific Embodiment approach 2

[0016] Specific embodiment 2: 3 mmol ZnCl 2 , 6 mmol FeCl 3Add 6H2O and 1.8g AC to 70 ml of ethylene glycol, stir evenly with a magnetic force, add 7.94 g of anhydrous sodium acetate, stir well, put it into a polytetrafluoroethylene-lined autoclave, and put it into a constant temperature drum Insulated in an air drying oven at 160 °C for 20 h. After cooling, use magnetic separation to separate the black product, wash it with deionized water and absolute ethanol until it is neutral, and then dry it at 80°C for 8 hours to obtain ZnFe 2 o 4 / AC Composite. Sol-Gel Synthesis of TiO 2 / ZnFe 2 o 4 / AC composite material: under stirring, add 2 ml of butyl titanate dropwise into 20 ml of absolute ethanol to prepare solution A. Mix 1 ml of anhydrous acetic acid, 1 ml of deionized water and 10 ml of absolute ethanol to prepare solution B. Under the condition of stirring, add solution B dropwise to solution A, after stirring for 1 h to obtain a transparent and clear sol, add 1 g o...

specific Embodiment approach 3

[0017] Specific embodiment 3: 3 mmol ZnCl 2 , 6 mmol FeCl 3 Add 6H2O and 1.8g AC to 70 ml of ethylene glycol, stir evenly with a magnetic force, add 7.94 g of anhydrous sodium acetate, stir well, put it into a polytetrafluoroethylene-lined autoclave, and put it into a constant temperature drum Incubate at 220 °C for 8 h in an air drying oven. After cooling, use the magnetic separation method to separate the black product, wash it with deionized water and absolute ethanol until it is neutral, and then dry it at 80°C for 10 hours to obtain ZnFe 2 o 4 / AC Composite. Sol-Gel Synthesis of TiO 2 / ZnFe 2 o 4 / AC composite material: under the condition of stirring, 3 ml of butyl titanate was added dropwise into 20 ml of absolute ethanol to prepare solution A. Mix 1 ml of anhydrous acetic acid, 1 ml of deionized water and 10 ml of absolute ethanol to prepare solution B. Under the condition of stirring, add solution B dropwise to solution A, after stirring for 1 h to obtain a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com