A hybrid excitation synchronous motor with built-in magnetic bridge combined rotor core

A hybrid excitation synchronous and rotor core technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, magnetic circuit rotating parts, etc., can solve the problem of increasing the axial length and overall weight of the motor, and unfavorable motor efficiency and system efficiency, eddy current loss increase, etc., to reduce the risk of demagnetization, expand the magnetic field adjustment performance, reduce eddy current loss and rotor heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

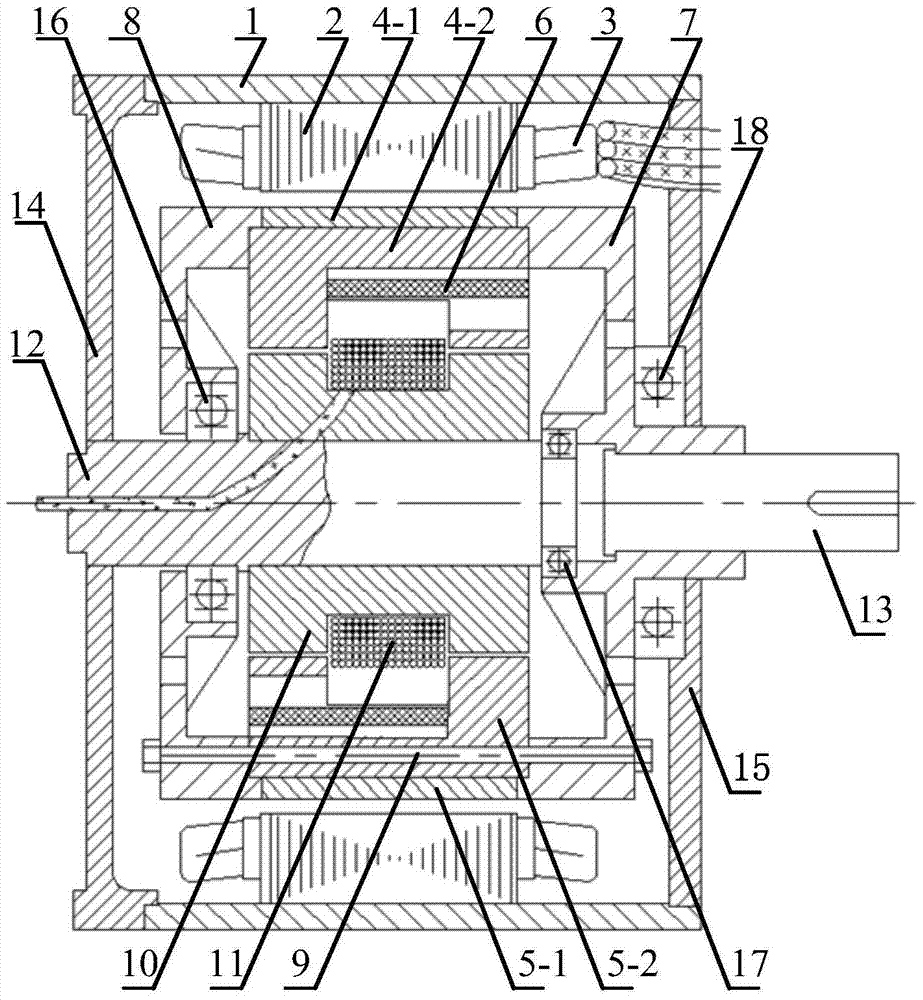

[0024] Such as figure 1 As shown, the present invention provides a combined rotor core hybrid excitation synchronous motor with a built-in magnetic bridge, including a casing 1 and a stator disposed in the casing 1, a rotor, a support shaft 12, and an annular guide fixed on the support shaft 12. The magnetic bridge 10 and the rotating shaft 13; the stator includes the stator core 2 and the armature winding 3 embedded in the stator slot; the stator core 2 is fixed on the casing 1 . The rotating shaft 13 is an output shaft and is arranged coaxially with the supporting shaft 12 .

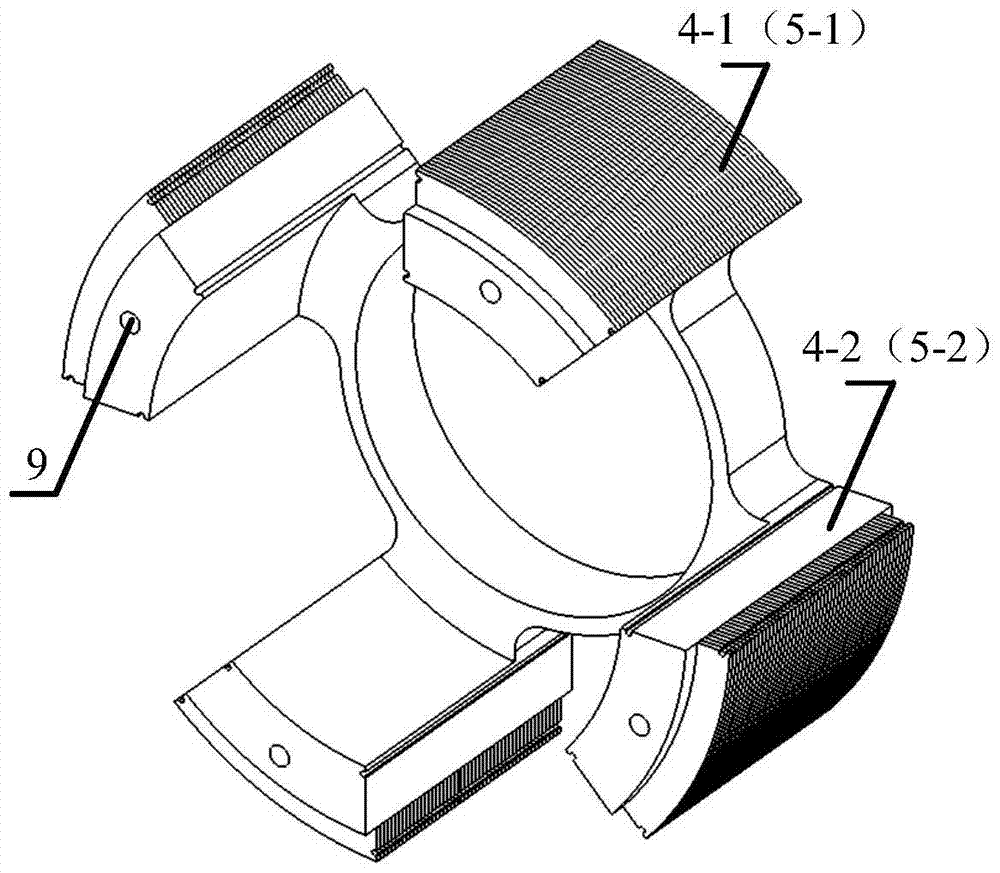

[0025] Denote the number of rotor pole pairs as p r , the rotor contains 2p r Block rotor core, 2p r The tangentially magnetized permanent magnets 6 , the front rotating bracket 7 , the rear rotating bracket 8 , and the interpole tie rods 9 with N poles and S poles interlacedly distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com