Track circuit anti-traction current interference test device based on virtual instrument

A technology of track circuit and traction current, which is applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems that the transient process of the critical interference test cannot be captured, the repeatability and synchronization of data processing are poor, and the problems cannot be quickly analyzed and diagnosed. Reaching the critical interference limit is scientific, easy to operate, and saves the effect of manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

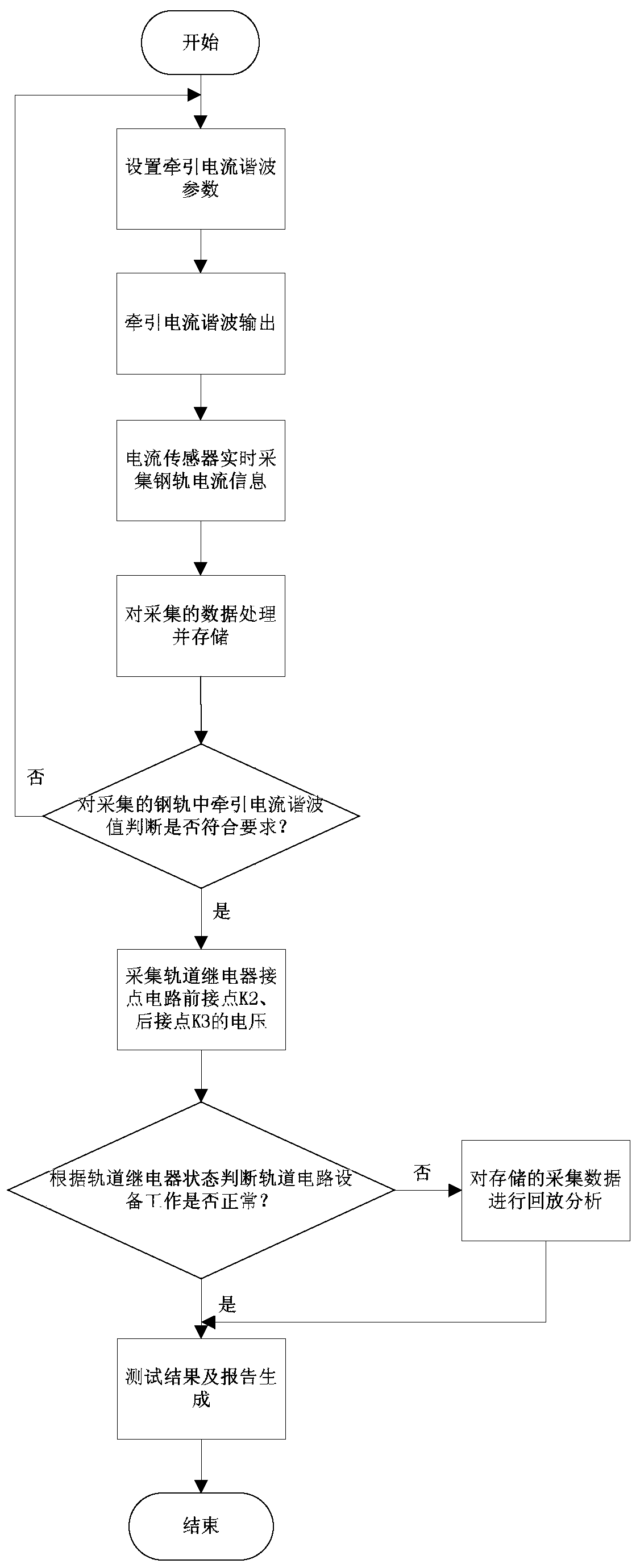

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

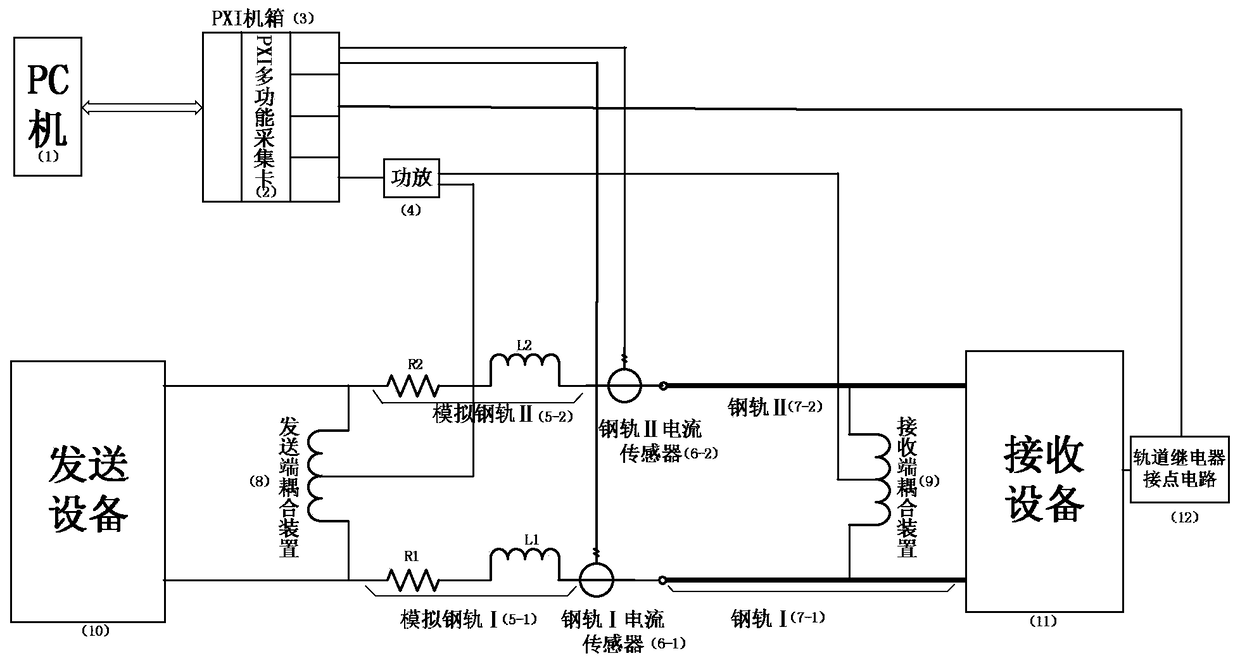

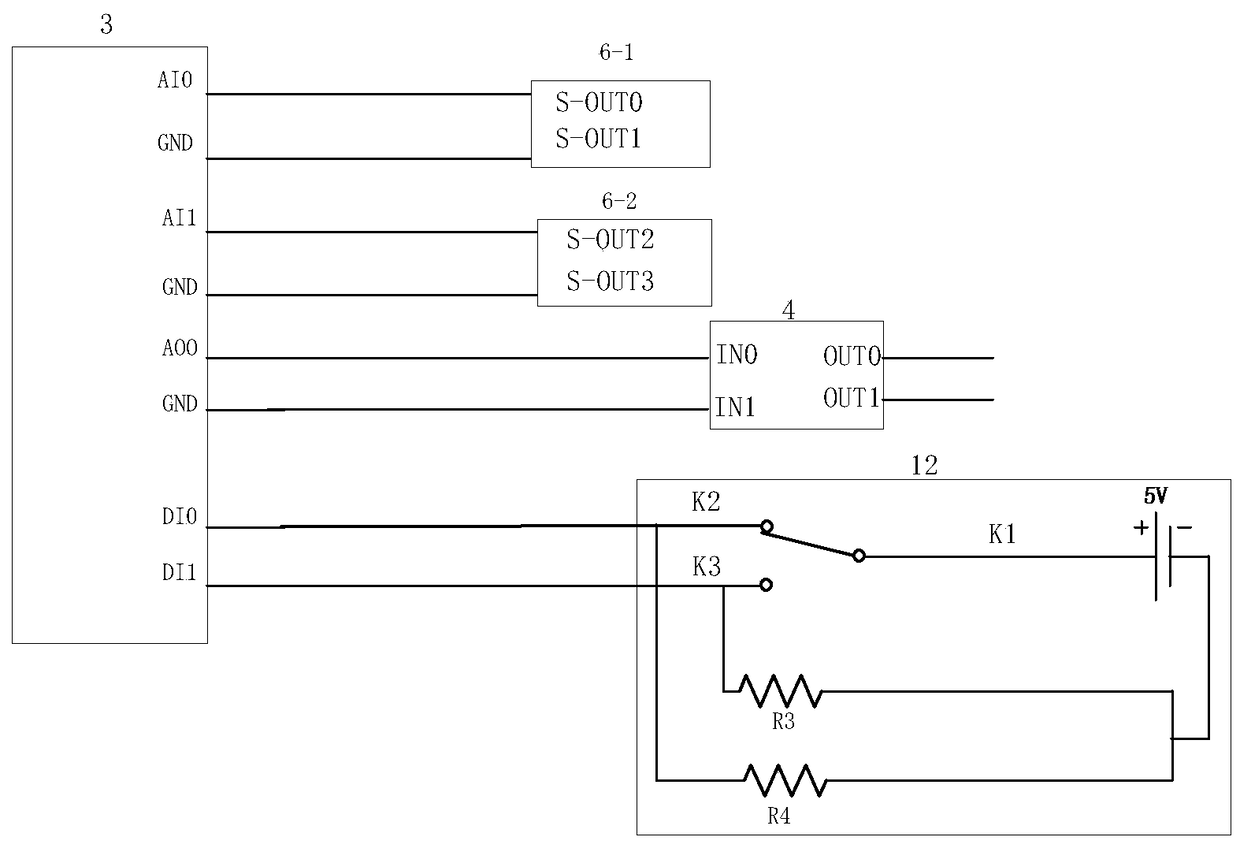

[0025] The track circuit anti-traction current interference test device based on virtual instrument, such as figure 1 , figure 2 . The device includes PC 1, PXI multi-function acquisition card 2, PXI chassis 3, power amplifier 4, simulated rail I5-1, simulated rail II5-2, rail I current sensor 6-1, rail II current sensor 6-2, rail I7-1, rail II7-2, sending end coupling device 8, receiving end coupling device 9, track relay contact circuit 12; sending device 10 and receiving device 11 are the equipment under test, and the described devices that constitute the device are Connect as:

[0026] The PXI multi-function acquisition card 2 is installed in slot 3 of the PXI chassis, and its analog output ports AO0 and GND are respectively connected to the input ports IN0 and IN1 of the power amplifier 4, and the output ports OUT0 and OUT1 of the power amplifier 4 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com