B-type hydraulic universal tester

A universal testing machine, hydraulic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of loss of limit, push out of oil cylinder 5, and damage of limit mechanism 17, so as to eliminate mechanical impact and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

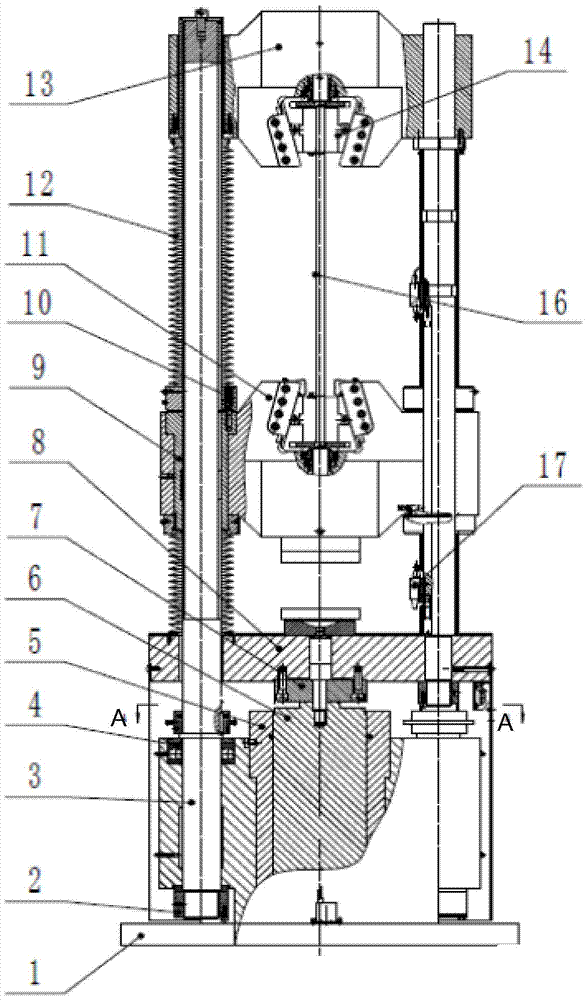

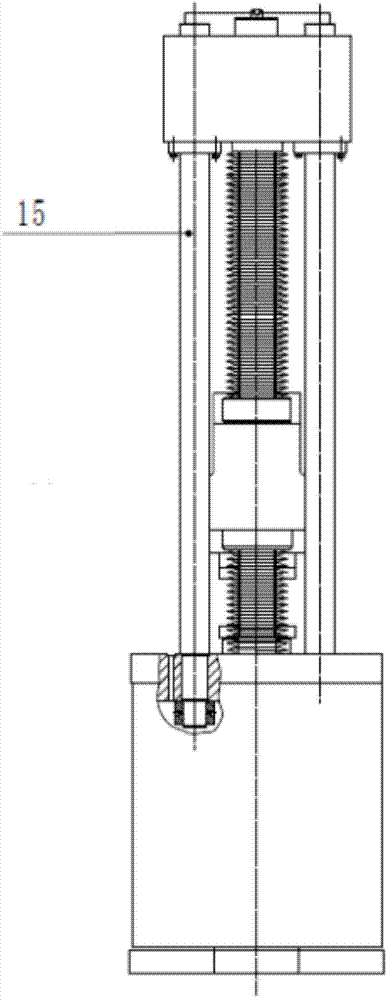

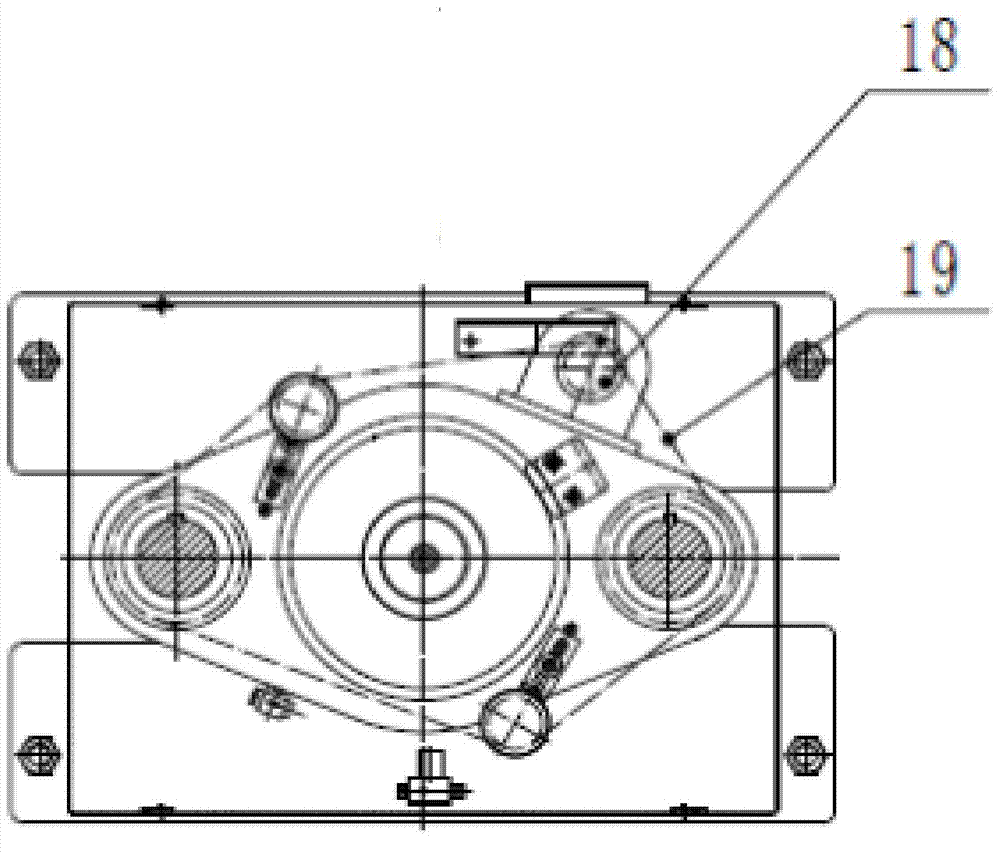

[0030] like Figure 4-Figure 8 as shown, Figure 4 for Figure 6 Internal cross-sectional view along C-C direction. The main components of the B-type hydraulic universal testing machine of the present invention are: base 25, main oil cylinder 26, main oil cylinder piston 27, column 28, column lock nut 29, main oil cylinder end cover 30, load sensor 31, test bench 32, Locking cylinder oil pipe 33, safety protection and noise isolation device 34, locking cylinder 35, lower beam 36, upper beam 37, hydraulic wedge clamp 38, polished rod 39, lifting cylinder piston rod 40, lifting cylinder 41, inner wall 42, Rear apron 43 , front apron 44 , oil pipe and cable transfer module 45 , and clamp oil pipe 46 .

[0031]Wherein, there is a through hole in the center of the base 25, and the main oil cylinder 26 is inserted in the center hole to form a radial positioning. 25 on. Two columns 28 are inserted in the through holes at two ends of the base 25 respectively. The main oil cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com