Bi-directional seal low-flow-resistance stop valve

A two-way sealing, low flow resistance technology, used in lift valves, valve devices, engine components, etc., can solve the problems of high flow resistance, unsuitable for reverse sealing, high performance requirements of the actuator, and achieve low flow resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

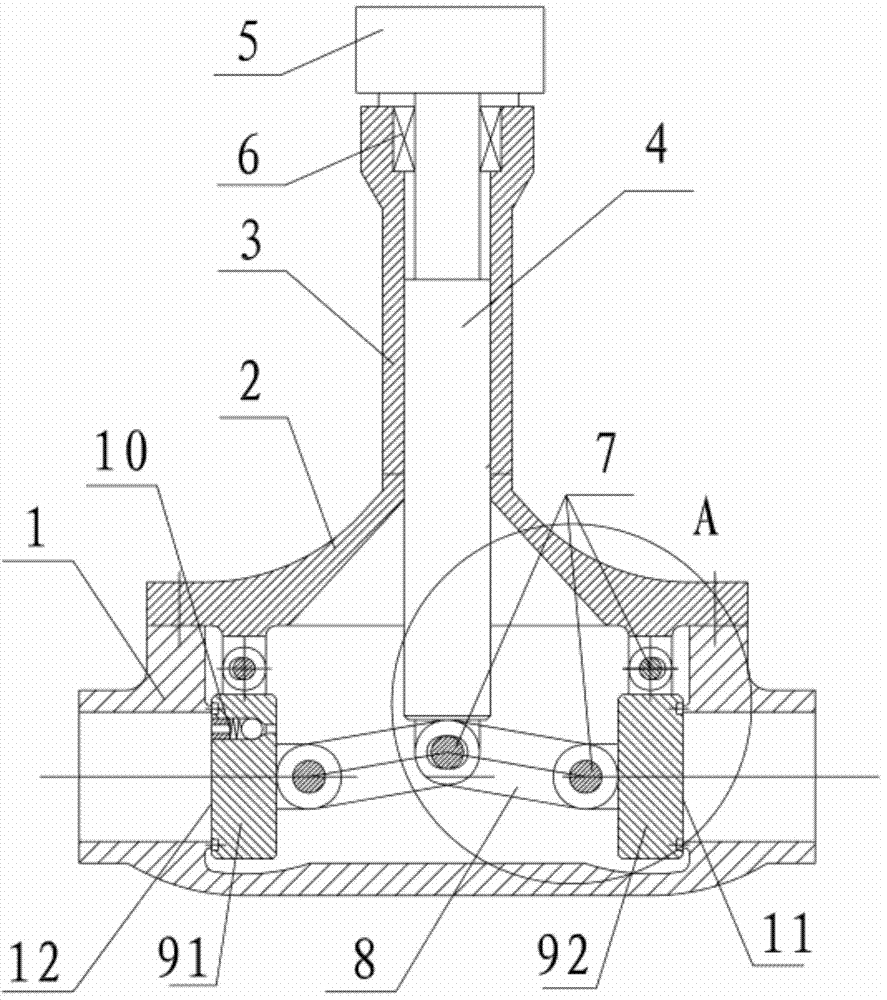

[0026] like figure 1 As shown, a two-way sealing low flow resistance cut-off valve includes a valve casing, a valve disc, a valve stem, and an actuator. There is a valve cavity in the valve casing, and the valve cavity has two ports of inlet and outlet. The inlet and outlet of the valve cavity Symmetrically opposite to each other, located on both sides of the valve cavity.

[0027] The valve casing includes a valve cover 2 and a valve body 1. The valve cover 2 is connected with the valve body 1 and encloses to form a valve cavity. The valve cover and the valve body are connected by flanges and bolts. The valve body 1 is provided with an inlet and outlet communicating with the valve chamber, the valve cover 2 is provided with a hollow valve neck 3 communicating with the valve chamber, and one end of the valve stem 4 passes through the valve neck 3 and enters the valve chamber.

[0028] One end of the valve stem 4 is connected with the actuator 5 located outside the valve chamb...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that: image 3 , 4As shown, the lengths of the two connecting rods connecting the valve stem and the two discs are different. The central axis of the valve neck is closer to the opening of the valve cavity where the valve disc connected by the shorter connecting rod is located, and the central axis of the valve neck is farther away from the opening of the valve cavity. The port of the valve cavity matched by the disc connected by the connecting rod is far away, and when the valve stem moves, it is ensured that both discs can close the matching port of the valve cavity. That is, the connecting rod connecting the valve stem and the first valve disc 91 is longer than the connecting rod connecting the valve rod and the second valve disc 92, the first valve disc 91 cooperates with the outlet 12, the second valve disc 92 cooperates with the inlet 11, and the center of the valve neck The axis is farther from the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com