An experimental method and experimental device for simulating laser drilling rock breaking

A technology of drilling and breaking rocks and experimental methods, which is applied in thermal drilling, earthwork drilling, wellbore/well components, etc. It can solve the problems of low accuracy of laser spot adjustment, difficulty in ensuring experimental accuracy, and rough experimental methods. To achieve the effect of simple and intelligent adjustment, real experiment, and environmental protection of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: simulated laser nitrogen drilling, comprising the following steps:

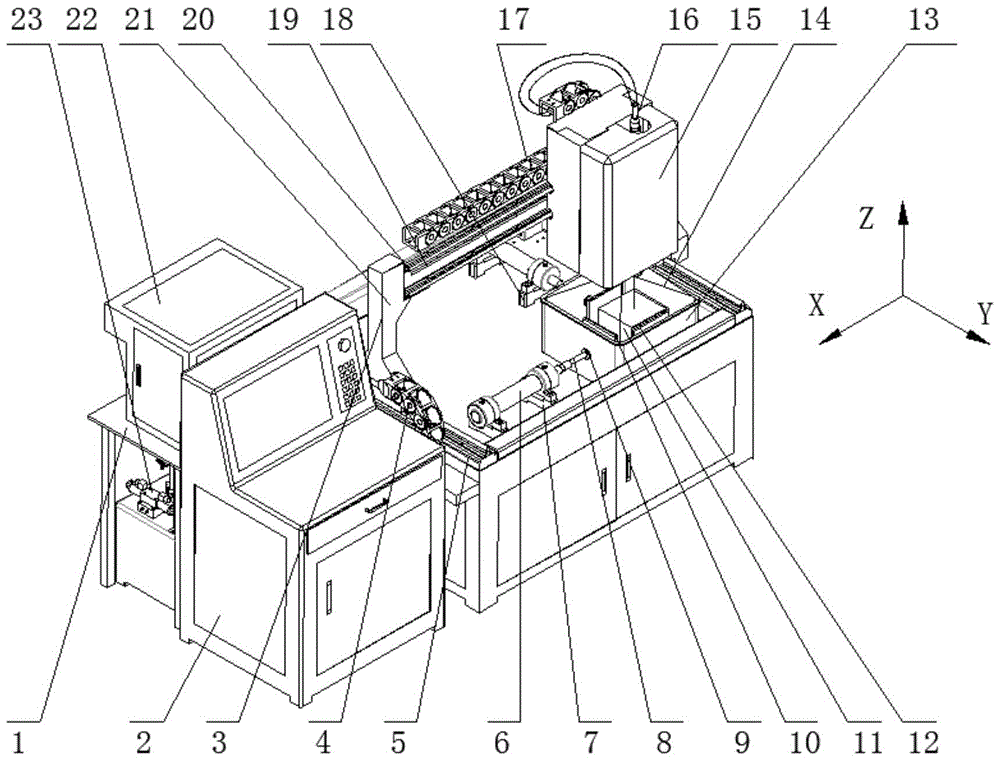

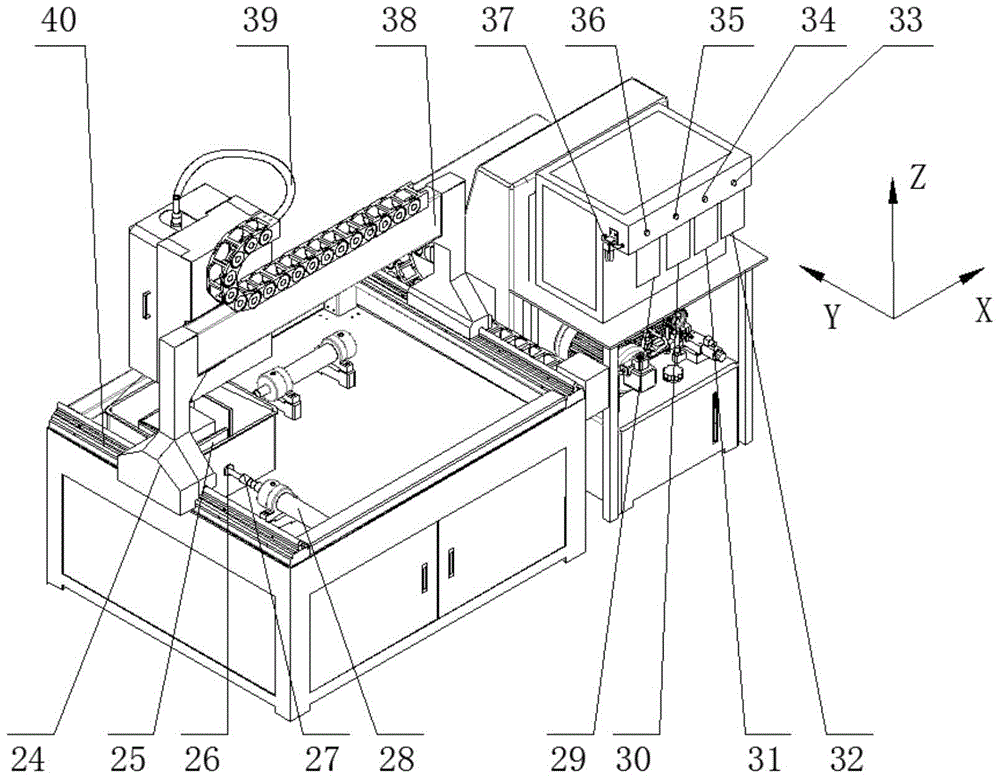

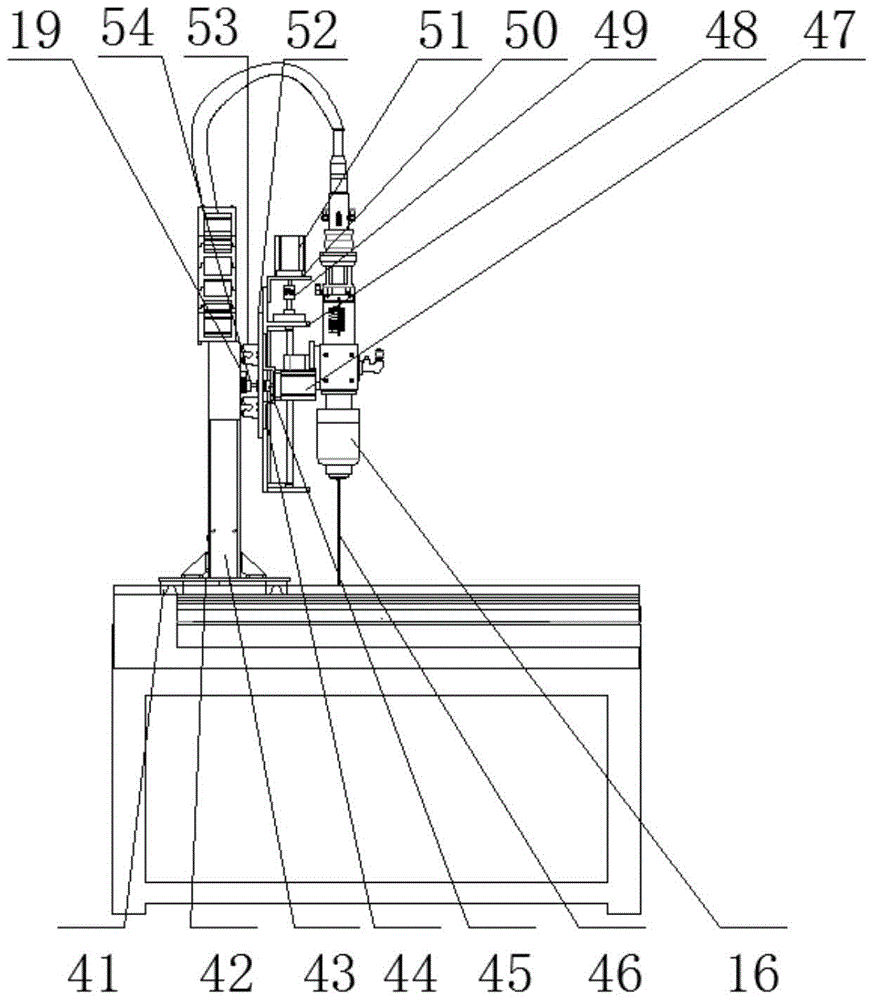

[0037] (1) Put the rock sample into a transparent sealed box, limit the displacement of the rock sample in the X-axis direction and the Y-axis direction, use the height sensor to measure and calibrate the surface height of the rock sample;

[0038] (2) Determine the breaking point of the rock sample, the interval between the breaking points is 35 mm, adjust and calibrate the position of each breaking point, and avoid the breaking point on the crack of the rock sample;

[0039] (3) Apply pressure to the rock sample along the X-axis direction and the Y-axis direction so that the rock sample is compressed to generate biaxial stress to simulate the stress of the formation rock, and then seal the sealing box;

[0040] (4) Introduce nitrogen gas into the sealed box from the air inlet of the sealed box, and pump air from the air outlet of the sealed box at the same time. The nitrogen is filled w...

Embodiment 2

[0041] Embodiment 2: simulated laser air drilling, comprising the following steps:

[0042] (1) Put the rock sample into a transparent sealed box, limit the displacement of the rock sample in the X-axis direction and the Y-axis direction, use the height sensor to measure and calibrate the surface height of the rock sample;

[0043] (2) Determine the breaking point of the rock sample, the interval between the breaking points is 35 mm, adjust and calibrate the position of each breaking point, and avoid the breaking point on the crack of the rock sample;

[0044] (3) Apply pressure to the rock sample along the X-axis direction and the Y-axis direction so that the rock sample is compressed to generate biaxial stress to simulate the stress of the formation rock, and then seal the sealing box;

[0045] (4) Fresh air is introduced into the sealed box from the air inlet of the sealed box, and at the same time, the air is pumped out from the air outlet of the sealed box. The fresh air ...

Embodiment 3

[0046] Embodiment 3: simulated laser helium drilling, comprising the following steps:

[0047] (1) Put the rock sample into a transparent sealed box, limit the displacement of the rock sample in the X-axis direction and the Y-axis direction, use the height sensor to measure and calibrate the surface height of the rock sample;

[0048] (2) Determine the breaking point of the rock sample, the interval between the breaking points is 35 mm, adjust and calibrate the position of each breaking point, and avoid the breaking point on the crack of the rock sample;

[0049] (3) Apply pressure to the rock sample along the X-axis direction and the Y-axis direction so that the rock sample is compressed to generate biaxial stress to simulate the stress of the formation rock, and then seal the sealing box;

[0050] (4) Helium gas is introduced into the sealed box from the air inlet of the sealed box, and at the same time, the air is pumped out from the air outlet of the sealed box, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com