Autoclaved sand aerated concrete block wall construction method based on BIM technique

A technology of air-entrained concrete and autoclaved sand, which is applied to the processing of walls, building materials, and building components. It can solve the problems of increasing engineering construction costs, increasing block cutting loss, and low work efficiency, so as to reduce engineering construction costs. cost, improve masonry efficiency, and reduce block loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

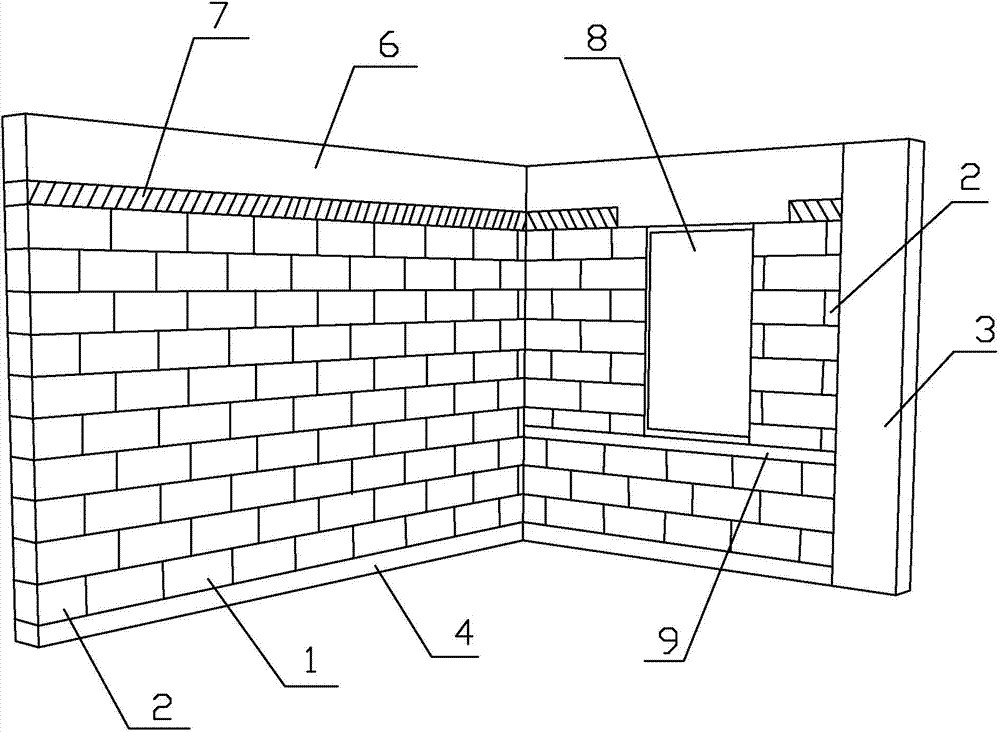

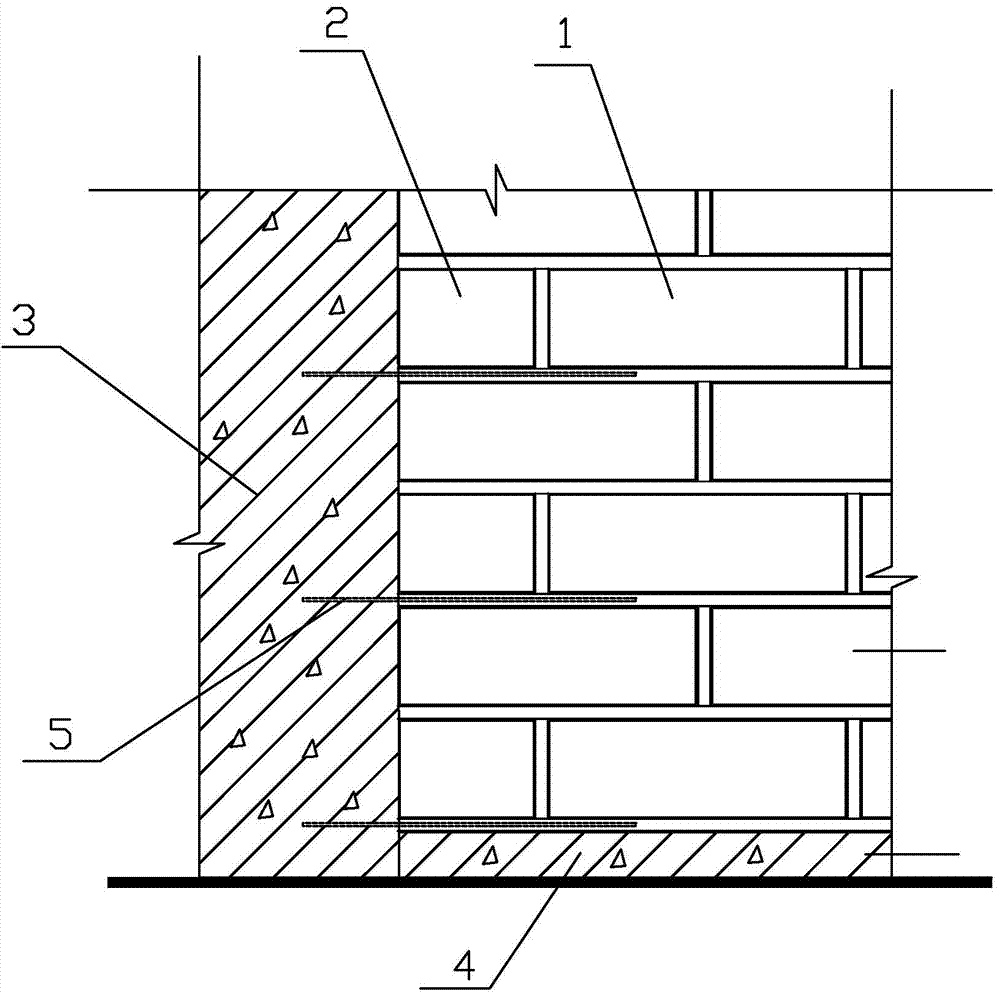

[0035] Embodiment: The construction method of autoclaved sand aerated concrete block wall based on BIM technology in this embodiment, the autoclaved sand aerated concrete block wall is built by autoclaved sand aerated concrete block into, such as figure 1 , figure 2 As shown, the autoclaved sand aerated concrete block includes a standard block 1 and a non-standard block 2, and the wall is built between the concrete columns 3 on the left and right sides, and there is a concrete flanging guide wall 4 at the bottom of the wall. Autoclaved sand aerated concrete blocks are used to build a skin masonry in turn on the concrete flange guide wall. Generally, the blocks at both ends of each skin masonry are non-standard blocks, and the middle blocks are standard blocks. Odd numbers The block joints of leather masonry and even skin masonry are set alternately. A number of tie bars 5 are pre-embedded in the concrete column 3 at intervals from top to bottom, and two skin masonry are bui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com