Novel electric tricycle frame

A technology for electric tricycles and frames, which is applied to motor vehicles, bicycles, transportation and packaging, etc. It can solve the problems of complex processing procedures, reducing the number of welding parts, and difficulty in ensuring the overall strength of the frame, so as to simplify processing procedures and reduce Quantity, the effect that the frame is not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

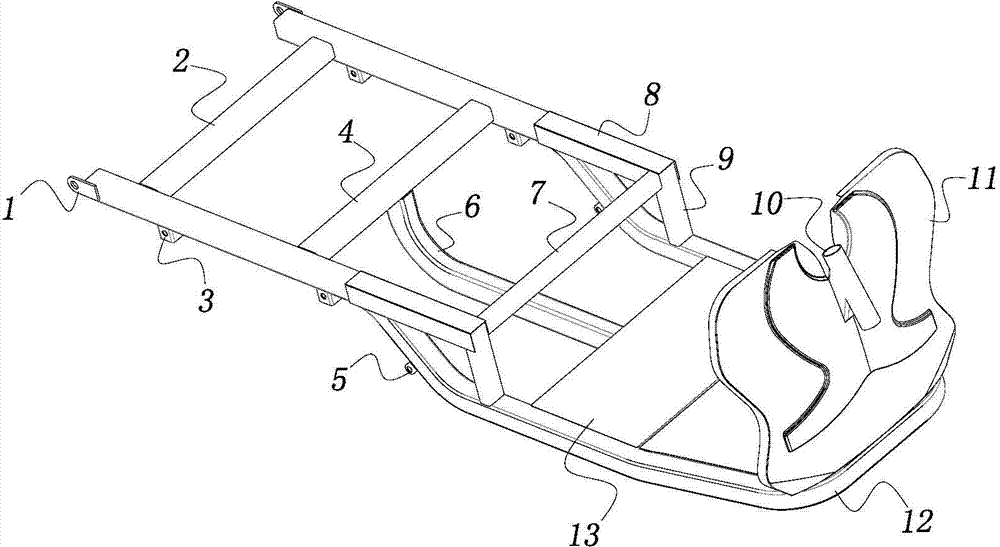

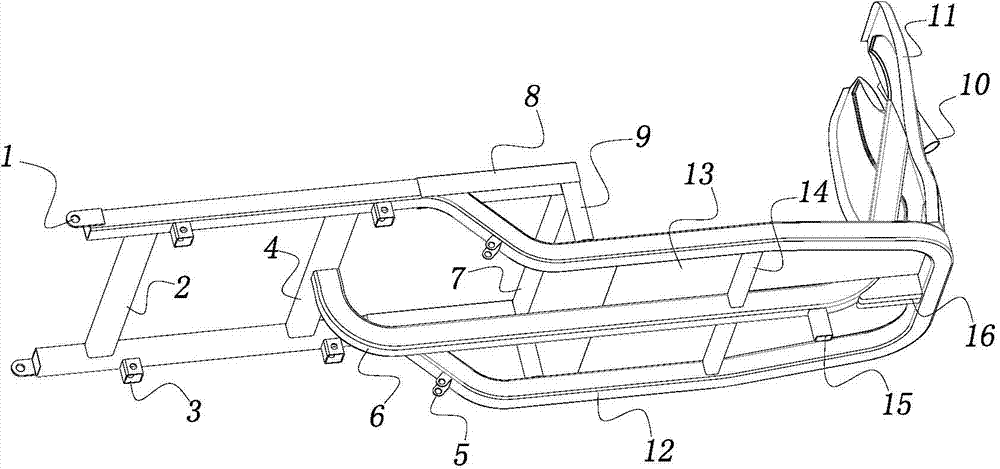

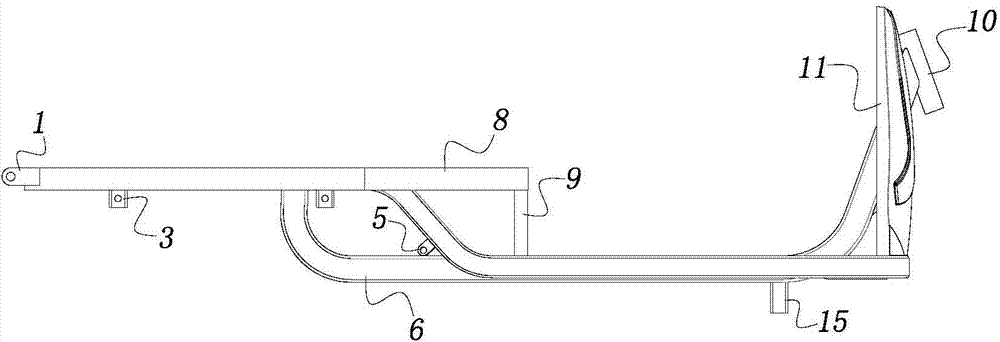

[0021] See Figure 1 to Figure 3 , the present invention includes a U-shaped main frame 12 obtained by bending and forming the same pipe material. The middle part of the main frame 12 is press-formed with a bent part, and the main frame 12 is divided into two parts: a front frame body and a rear frame body. . The front frame body is lower than the rear frame body in the vertical direction, forming a stepped shape. Wherein, the top of the front frame body forms the space for placing the seat and the feet of the rider, and the rear frame body is used for installing the vehicle bucket of the electric tricycle.

[0022] A tail crossbeam 2 is erected and fixedly connected between the ends of the rear frame bodies, and a first middle crossbeam 4 is erected and fixedly connected between the middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com