A pipeline all-position operating machine and its control method

A control method and technology of operating machines, applied in auxiliary devices, manufacturing tools, gas flame welding equipment, etc., to achieve the effect of light weight, small volume and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with example, specifically introduce technical scheme of the present invention:

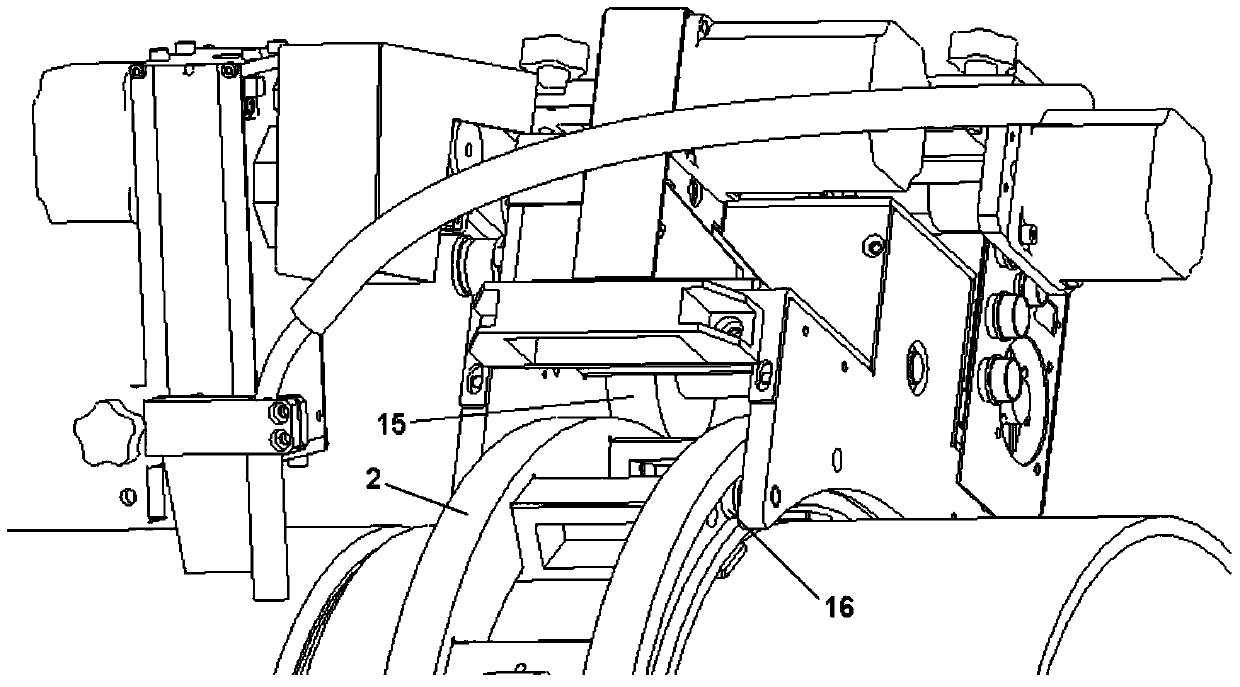

[0040] Such as figure 1 As shown, a pipeline all-position working machine includes a guide rail 2 , a motion unit, an execution terminal 10 , a drive unit 12 and a control unit 13 . The motion unit includes a circumferential motion mechanism 3 , an axial motion mechanism 4 , a radial motion mechanism 5 , and a swing mechanism 6 . The output terminal of the control unit 13 is connected with the input terminal of the driving unit 12, and sends out a pulse signal. The output ends of the driving unit 12 are respectively connected to the driving motors of the motion unit, and the driving unit 12 receives the pulse signal sent by the control unit 13 and drives the driving motor of the motion unit to perform corresponding actions.

[0041] The guide rail 2 is a complete track formed by connecting two semicircular components through the support piece 9 , and the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com