Method for clamping square bar on three-jaw self-centering chuck

A self-centering chuck and clamping technology, which is applied in the field of clamping, can solve problems such as insufficient clamping stability, and achieve the effect of enhancing stability and increasing clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

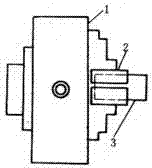

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, the present invention includes the following steps: (1), select a hollow tube with an inner diameter slightly larger than the square rod and cut it along the longitudinal direction; (2), insert the square rod into the hollow tube; (3), insert the The hollow tube with the square rod is snapped onto the three-jaw self-centering chuck.

[0010] The hollow tube is preferably made of elastic material, so that when clamped by the claws, it can be further contracted due to the existence of the longitudinal seam so that the opposite rod can generate uniform pressure and strengthen the clamping force.

[0011] The present invention has been exemplarily described above in conjunction with the accompanying drawings. Obviously, the specific implementation of the present invention is not limited by the above methods, as long as various insubstanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com