Sorting system based on grouping mode and light label and implementation method of sorting system

A sorting system and lighting technology, applied in sorting, transportation and packaging, storage devices, etc., can solve the problems of unsuitable fruit and vegetable sorting, high cost of sorting equipment, and easy sorting errors. The effect of promoting use, high efficiency and accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

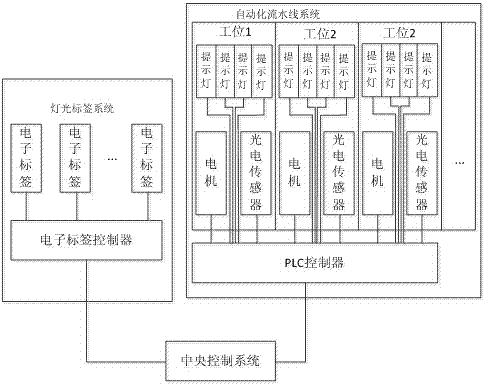

[0039] Such as figure 1 As shown, a sorting system based on grouping mode plus light labeling includes an automated assembly line system, a light labeling system installed on the automated assembly line system, and a central control system that simultaneously controls the work of the light labeling system and the automated assembly line system. In the example, the automated assembly line system is divided into a mechanical part and an electronic system part. The mechanical part includes a conveyor belt and shelves on both sides of the conveyor belt. The mechanical part is divided into multiple stations, and the shelves in each station are divided into multiple layers. There are multiple temporary storage positions; the electronic system part includes a PLC controller connected to the central control system, a motor and a photoelectric sensor connected to the PLC controller and located on each station, the motor controls the movement of the conveyor belt, In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com