BMP-loaded silk fibroin/collagen scaffold material and preparation method thereof

A collagen and silk fibroin technology, applied in medical science, prosthesis, etc., to solve the effect of short half-life, prolong function, and prolong full play

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of loose layer silk fibroin / collagen film and dense layer silk fibroin / collagen film

[0026] 1. Preparation of silk fibroin

[0027] Cut silkworm cocoons into pieces and add 0.5% Na 2 CO 3 solution, in a constant temperature water bath at 98±2°C for 30 min, twice in total. After taking it out, wash it twice with boiling water, and then wash it 8 times with deionized water. Dry in an oven at 60°C to obtain dry silk fibroin. Weigh the silk fibroin silk after silk degumming, use CaCl 2 / H 2 O / C 2 h 5 OH solution (molar ratio 1:8:2) was dissolved in a constant temperature water bath at (78±2)°C, and the bath ratio was 1:25. Filter with gauze to obtain the silk fibroin stock solution. Dialyze with a fibrous semipermeable membrane dialysis bag with a molecular weight cut-off of 8000 D-14000 D for 3 days to remove calcium chloride and ethanol. Filter to obtain silk fibroin solution.

[0028] 2. Collagen preparation

[0029] Cut the fish skin...

Embodiment 2

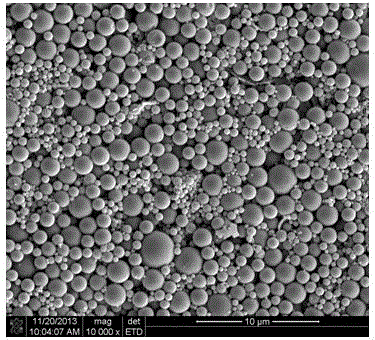

[0035] Embodiment 2: Preparation of microspheres loaded with BMP-2

[0036]Weigh 0.25 g of PLGA, dissolve in 2.5 mL of dichloromethane, and set aside in an ice bath. Weigh 100 uL of 2% BMP-2 solution, emulsify for 2 min at 5000-15000 r / min to form colostrum, immediately pour 25 mL of 0.5% PVA solution, and pass through a homogenizer at 8000 r / min Stir for 1 min to form double emulsion. Magnetically stirred for 4 h to evaporate the organic solvent. The double emulsion was centrifuged at 8000 rpm for 8 min at a constant temperature of 4°C, washed 5 times with deionized water, and freeze-dried to obtain PLGA microspheres loaded with BMP-2 ( figure 1 ). The particle size distribution and potential distribution of PLGA microspheres were normal, and the particle size and Zeta potential distribution of most microspheres were concentrated. Average particle size: 1233nm, average Zata potential: -29.7mV.

Embodiment 3

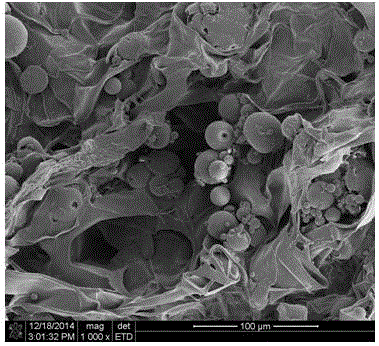

[0037] Example 3: Preparation of BMP-loaded silk fibroin / collagen scaffold material

[0038] Wet the cross-linked loose layer silk fibroin / collagen membrane prepared in Example 1 with double-distilled water and spread it flat, and add the aqueous solution of PLGA microspheres loaded with BMP-2 prepared in Example 2 to the surface at 4-8 °C Air-dry until there is no flowing liquid on the surface, then wet the cross-linked dense layer silk fibroin / collagen film and spread it on the upper surface of the cross-linked loose layer silk fibroin / collagen film, and air-dry at 4-8°C to obtain BMP-2-loaded silk Vegetarian protein / collagen scaffold material ( figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com