Template for sewing non-ironing sleeve tab

A technology of templates and small loops, applied to sewing tools, sewing equipment, sewing machine components, etc., can solve the problems of difficult sewing, slow sewing speed, easy deviation of sewing threads, etc., and reduce the difficulty of sewing , Improve the sewing speed, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

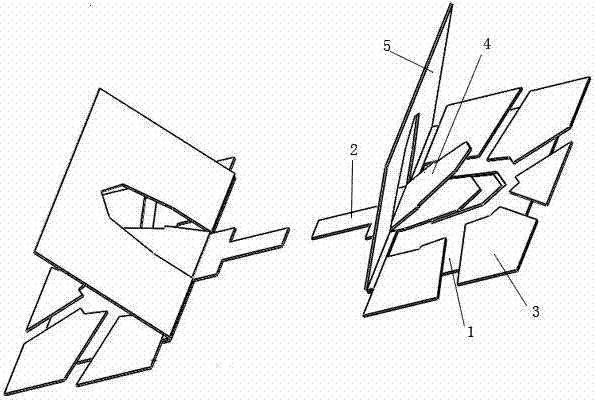

[0014] Such as figure 1 As shown, the template for sewing non-ironing small loops includes two hemming templates that can be opened or closed relative to each other. The hemming template includes a track groove plate 1 that is the same as the sewing curve on the first layer, and the curve is in the shape of a small loop , the second layer is a movable platen 2 that cooperates with the outer edge of the track groove, a movable edge plate 3 is arranged around the curved edge of the movable platen 2, and the sides corresponding to each other of the movable platen 2 and the movable edge plate 3 are wedge shapes that cooperate with each other. The third layer is the edge plate 4 consistent with the edge of the track groove, and the outside of the edge plate 4 is a support plate 5 consistent with the outer edge of the track groove.

[0015] The movable flange plate 3 of the template of non-ironing small loop is ten.

[0016] The sum of the thicknesses of the track groove plate 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com