Device and method for controlling gas in cultivating tank

A technology of a control device and an incubator, which is applied in the direction of electric fluid pressure control, non-electric variable control, control/regulation system, etc., can solve the problems of short effective service life, increase cost, etc. The effect of a wide pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

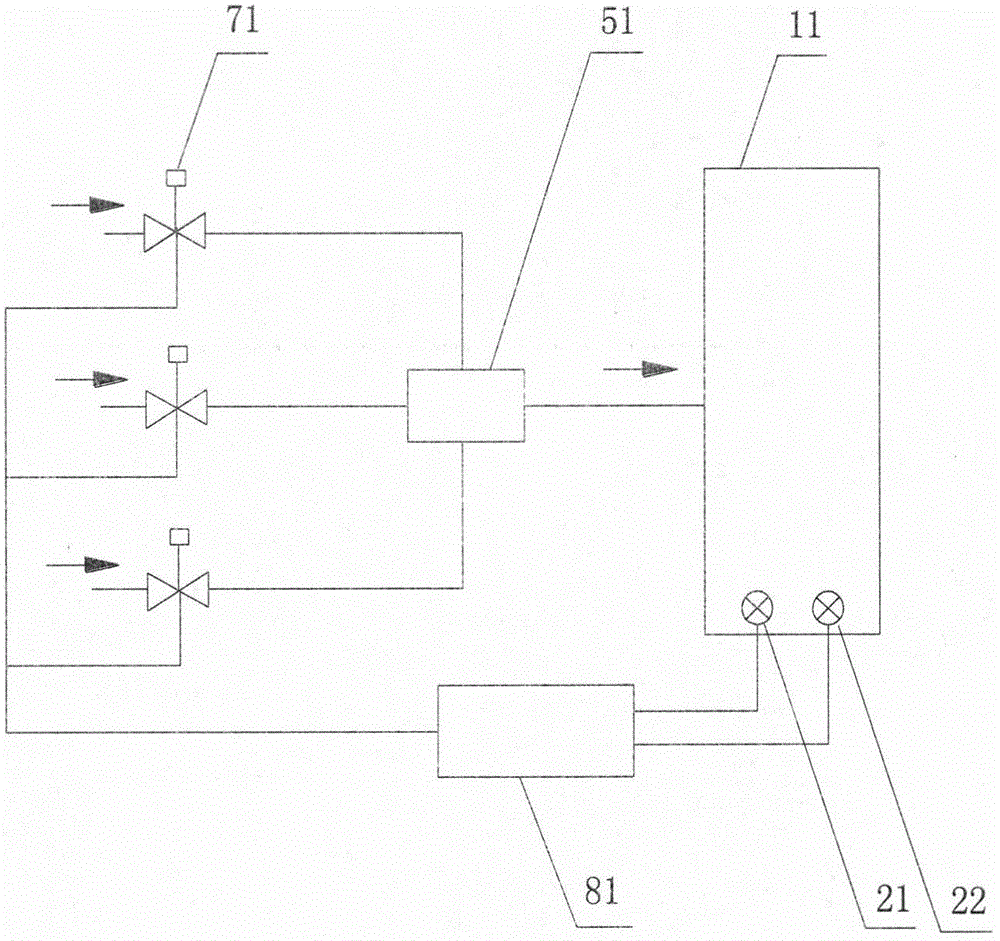

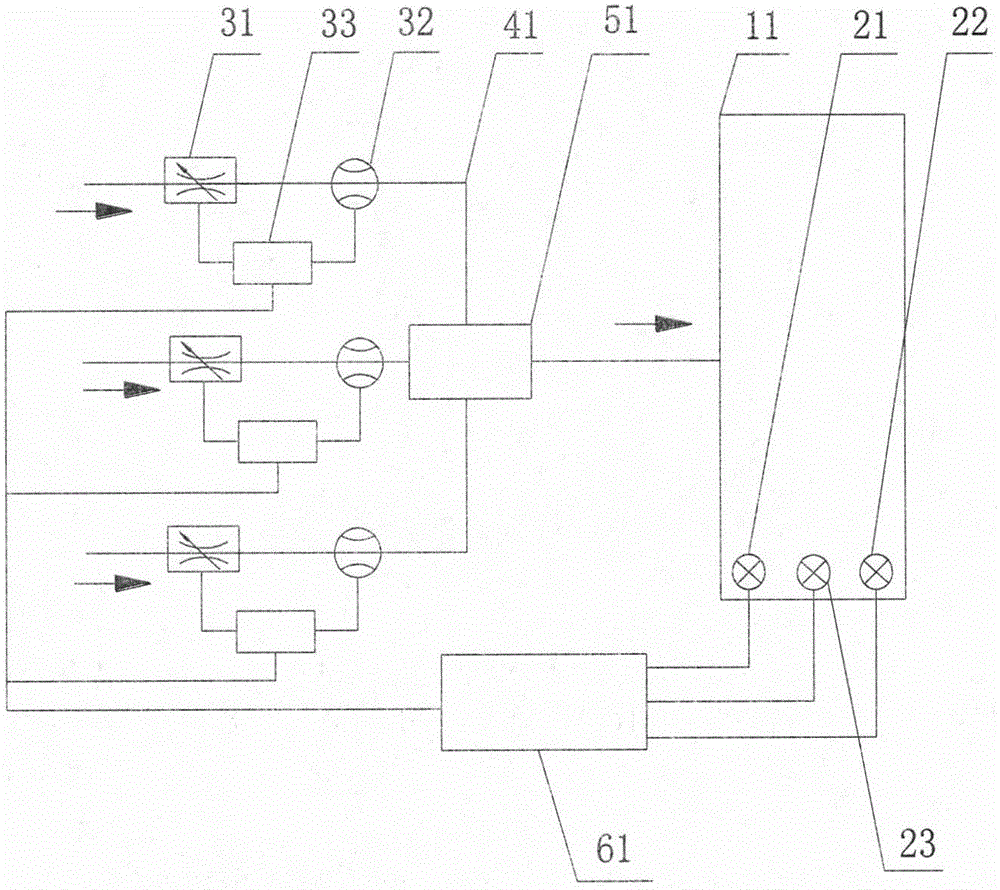

[0041] figure 2 Schematically provides a simplified structural diagram of the gas control device in the incubator of the embodiment of the present invention, as figure 1 As shown, the control device includes:

[0042] At least two gas sources are connected to the mixing unit 51, and then input into the incubator 11, such as nitrogen, carbon dioxide, and oxygen;

[0043] A pressure sensor 23, the pressure sensor 23 is arranged on the incubator 11, and the output end is connected to the control unit 61;

[0044] Gas sensors 21, 22, the gas sensors are used to detect the content of at least one gas in the incubator 11, used to detect the content of carbon dioxide and oxygen, and send it to the control unit 61;

[0045] A control unit 61, the control unit 61 is used to adjust the flow rate of the at least two channels of gas according to the received pressure and gas content, and the adjustment instruction is sent to the adjustment unit;

[0046] An adjustment unit, the adjust...

Embodiment 2

[0061] An application example of the control device and its working method according to Embodiment 1 of the present invention.

[0062]In this application example, the control target is: the pressure in the incubator and the content of oxygen and carbon dioxide meet the requirements. The pressure in the incubator ranges from 80-150kPa, the oxygen content ranges from 1-19%, and the carbon dioxide content ranges from 0-20%.

[0063] The control device is as follows: an oxygen sensor, a carbon dioxide sensor and a pressure sensor are set on the incubator, and a first pipeline and a first flow sensor are also set, and the second to fourth pipelines are respectively used to feed oxygen, carbon dioxide and nitrogen into the incubator. Second to fourth proportional valves, second to fourth flow sensors and second to fourth flow control modules are respectively arranged on the second to fourth pipelines. A proportional valve, a flow sensor and a flow control module on each pipeline f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com