Temperature control system of power curing oven

A technology of temperature control system and curing furnace, which is applied in the direction of using electric mode for temperature control, etc., can solve problems such as the inability to meet the performance requirements of home appliance boards, and achieve the effect of high degree of automation, high temperature control accuracy, and easy use and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

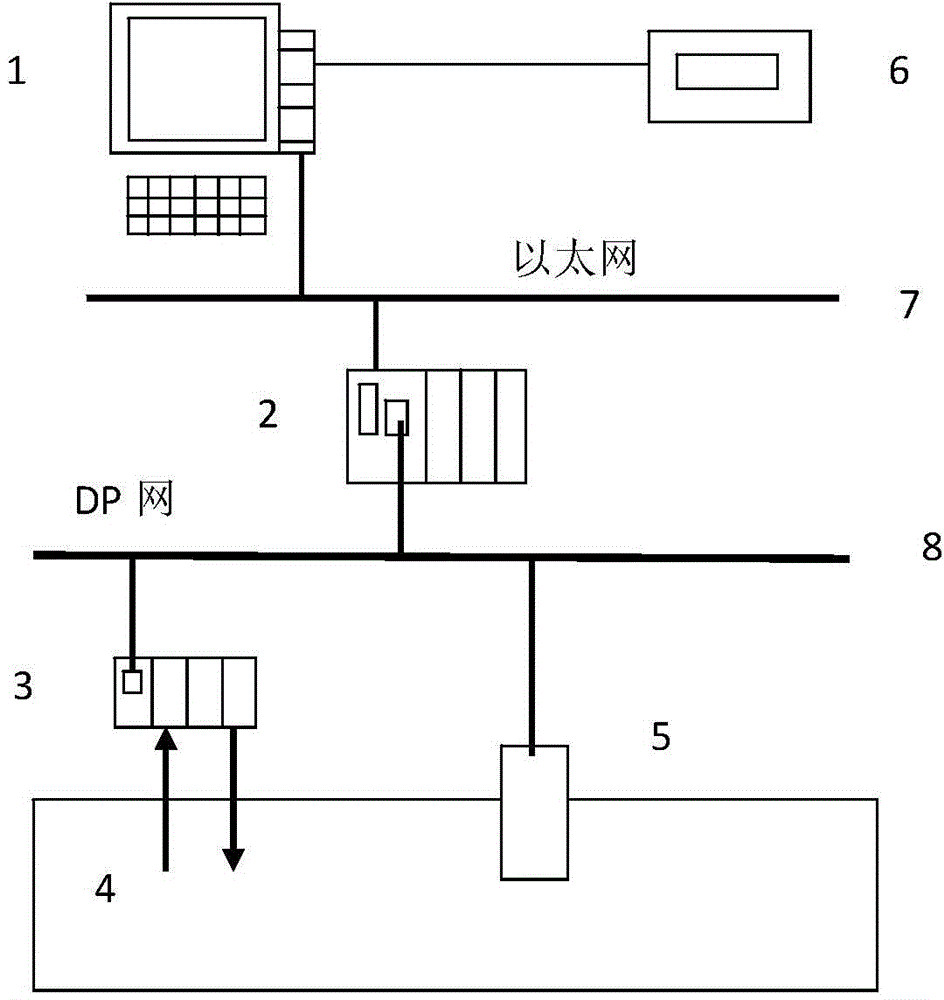

[0013] refer to figure 1 , the powder curing furnace temperature control system of the present invention includes a curing furnace 4 and a radiation heating unit 5 arranged in the curing furnace 4, a furnace temperature detection unit and an actuator, as well as an upper computer 1, a lower computer 2 and a remote station 3. The upper computer 1 is connected with the lower computer 2 through Fast Ethernet 7 . The lower computer 2 is connected to the remote station 3 and the radiation heating unit 5 respectively through the field bus 8 .

[0014] In the embodiment of the temperature control system for the powder curing furnace of the present invention, the upper computer 1 is an industrial control computer, and is connected to the lower computer 2 by using an Ethernet card. The upper computer 1 is provided with a communication module, and the communication module is composed of CP343-1 and CP345 modules. The remote station 3 is composed of ET200 modules. The upper computer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com