Lift type blade airfoil for vertical-axis wind turbine generator system

A technology of wind turbines and lift-type blades, which is applied to wind turbines, wind turbines at right angles to the wind direction, engines, etc., and can solve problems such as low maximum lift-to-drag ratio, sensitive leading edge roughness, and low workability. Achieve the effects of improving structural strength, increasing airfoil thickness, and improving wind energy utilization coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

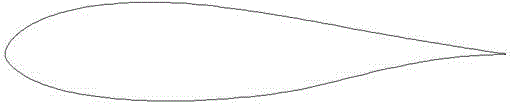

[0023] Referring to the accompanying drawings: the present invention is through a large amount of aerodynamic performance scientific tests and repeated test verification after the test data is corrected, and the key data of the following blade airfoils are obtained as follows:

[0024] (1) The maximum camber of the blade airfoil is 19.8% at the chord of 30.4%;

[0025] ⑵, the maximum surface 0.59% at 22.3% chord;

[0026] ⑶, airfoil leading edge radius 1.8523%;

[0027] ⑷, airfoil trailing edge thickness 0.15%.

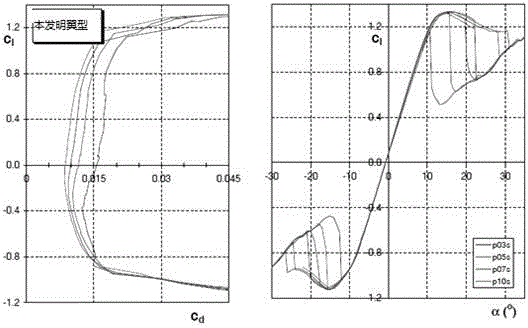

[0028] The blade airfoil covers a wider range of angles of attack between 150,000 and 700,000 Reynolds numbers, and the absence of laminar flow separation at the trailing edge reduces noise. The stall occurs after a high angle of attack, and there is a limited decrease in the lift coefficient after the stall.

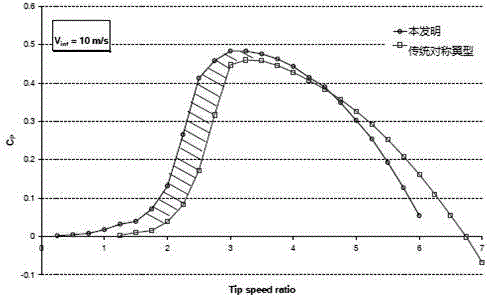

[0029] The blade airfoil of the present invention has good lift performance, specifically see attached figure 2 .

[0030] The blade airfoil of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com