A self-protected wind-powered water-lifting system with speed-increasing blades

A self-protection and blade technology, which is applied in the direction of wind turbines, wind turbines, and wind motor combinations in the same direction as the wind, can solve the problems of large number of blades and low utilization rate of wind energy, and achieve reduction of blade tip vortex and wind energy utilization coefficient The effect of lifting and facilitating hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

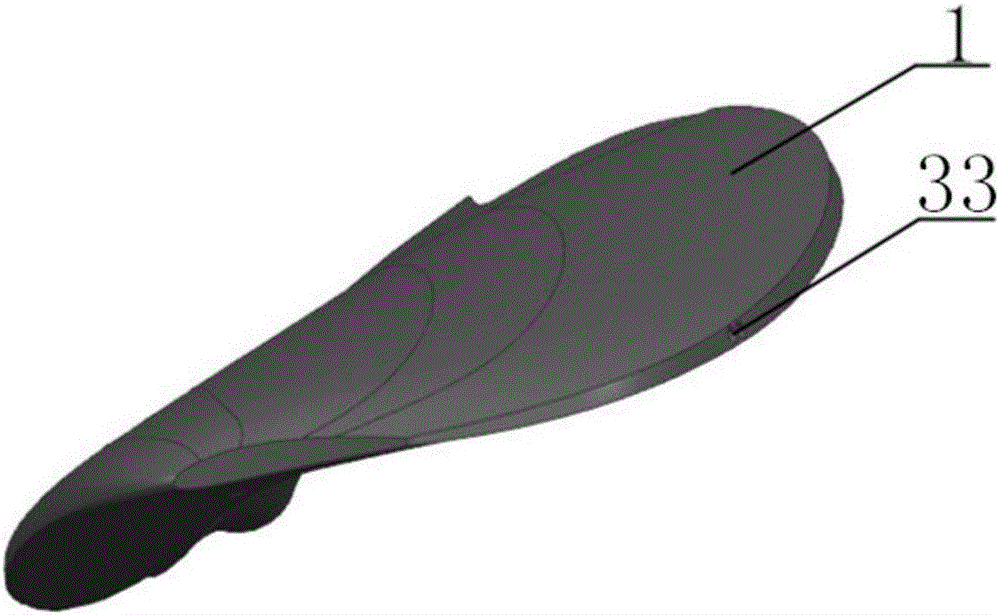

[0048] Embodiment 1: When the head is 5m and the incoming wind speed is 2.7m / s, the blade (1) of the self-protected wind water lifting unit with speed-increasing blades of the present invention starts to rotate, and now the water lifting mechanism can be directly driven Start to work and lift water; when the wind speed is 3m / s, the rotating speed of the blade (1) is stable, and the rotating speed of the blade (1) of the wind power water lifting unit with load is 25r / min; when the wind speed increases to 8m / s When the rated wind speed is , the speed of the blade (1) of the wind power water lifting unit is 75r / min, and the water lifting flow rate is 25m when the head is 5m 3 / h~30m 3 / h, wind energy utilization rate ≥ 0.42.

Embodiment 2

[0049] Embodiment 2: When the lift is 9m and the incoming wind speed is 2.7m / s, the blade (1) of the self-protection wind water lifting unit with speed-increasing blades of the present invention has begun to rotate. The rotating speed of the blade (1) is 27r / min. At this time, the wind power transmission mechanism has not driven the water lifting mechanism to work; when the wind speed reaches 3m / s, the wind power water lifting unit drives the water lifting mechanism to start working and lift water; when the wind speed is 3.5 At m / s, the rotating speed of the blade (1) of the wind power water lifting unit is stable. At this time, due to the load on the unit, the rotating speed of the blade (1) reaches 30r / min; when the wind speed increases to the rated wind speed of 8m / s, the wind power lifts The rotating speed of the blade (1) of the water unit is 65r / min, and the water lifting flow rate is 10m 3 / h~15m 3 / h, wind energy utilization rate ≥ 0.42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com