One-shaft two-machine horizontal vehicle turbocharger

A technology of turbo and supercharger for vehicles, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of large lubricating oil flow, high pressure and high cost, to ensure normal operation, long service life, working smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below in conjunction with embodiment and accompanying drawing.

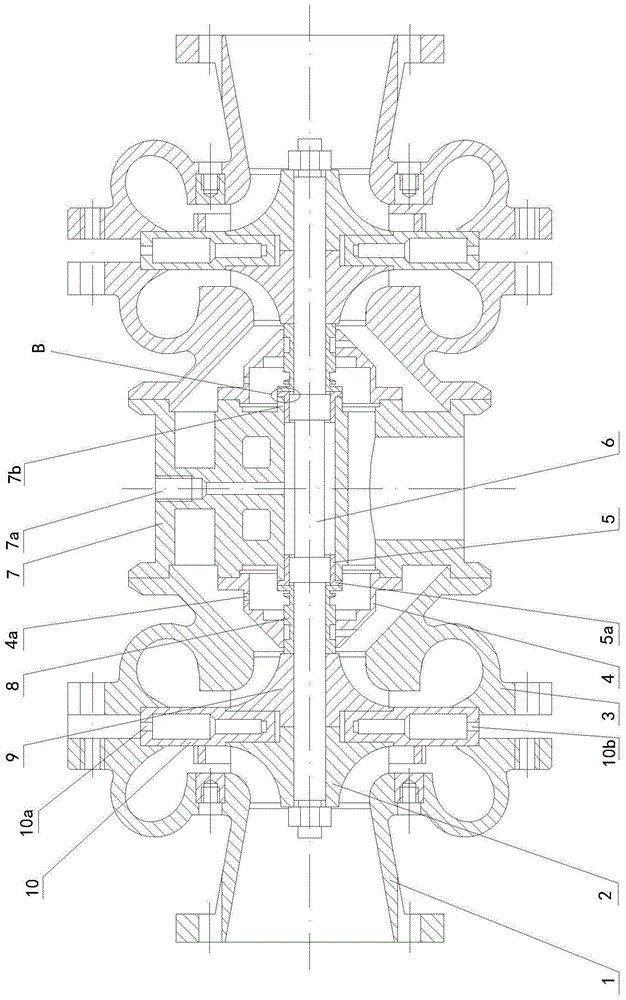

[0014] see figure 1 , Figure 5

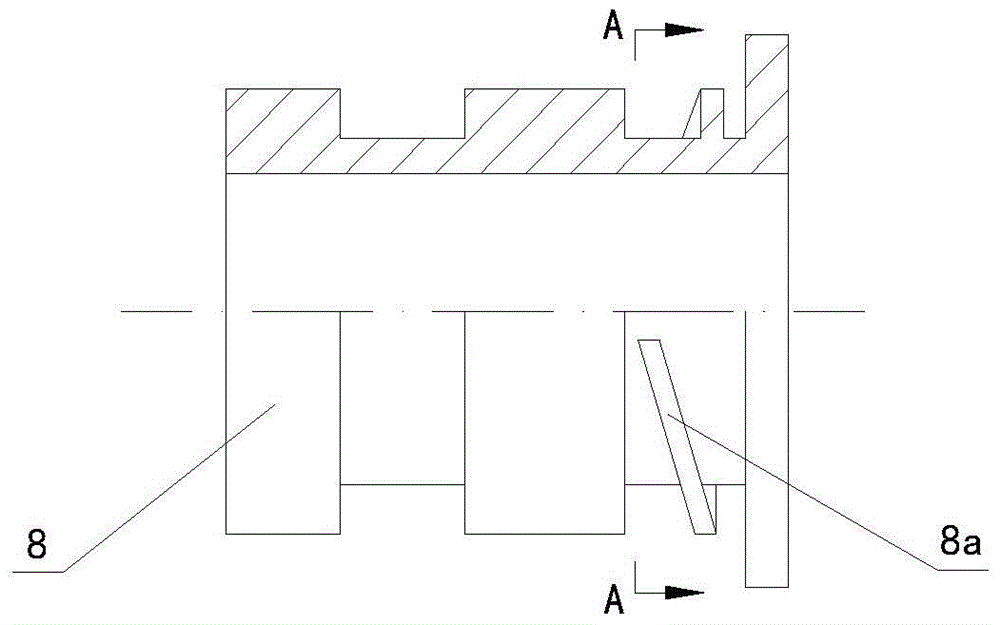

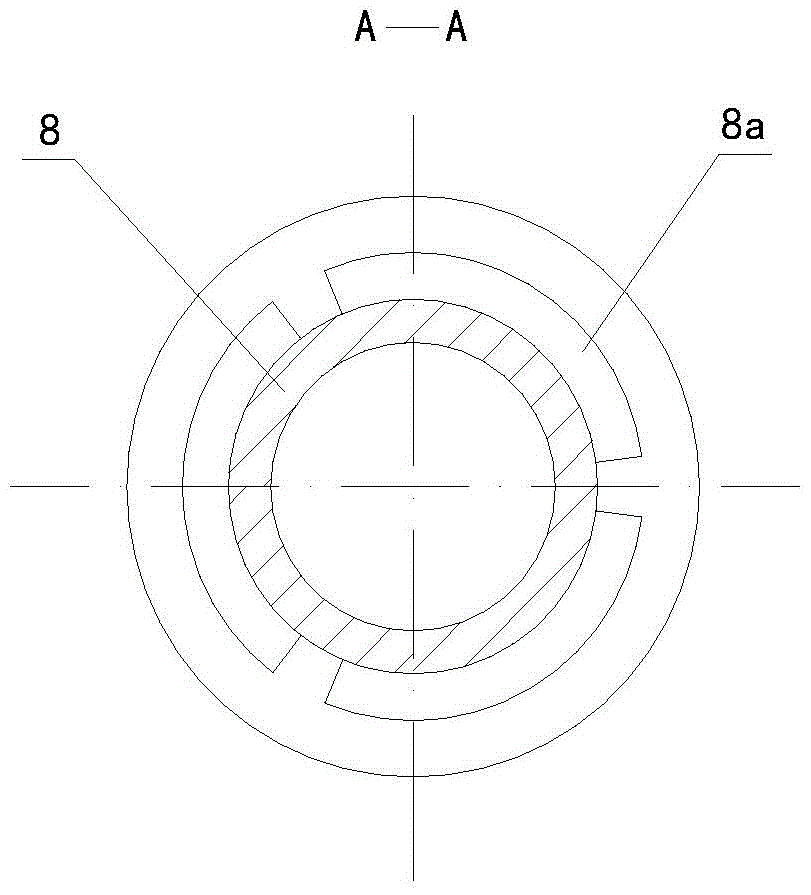

[0015] The one-shaft two-machine horizontal vehicle turbocharger provided by the present invention is a one-shaft two-machine type, and the two sides of the bearing shell 7 it has are respectively connected with a compressor casing 3, and each compressor casing 3 passes through the The heat shield 10 is connected and paired with a turbine casing 1 . The inner hole of the bearing shell 7 is equipped with a rotating shaft 6, and the two ends of the rotating shaft 6 are respectively located in the paired compressor shell 3 and the turbine shell 1 on both sides of the bearing shell 7, and the compressor impeller 9 in each compressor 3 shell And the turbine wheel 2 that has in each turbine casing 1 is contained on the rotating shaft 6. The two ends of bearing housing 7 are also equipped with bearing cover 4 respectively, are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com