Oval ring unit aeration system

A technology of aeration system and annular unit, applied in the field of aeration system, can solve the problems of high operation and maintenance cost, easy occurrence of aeration dead angle, inconvenient operation and maintenance, etc. The effect of reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

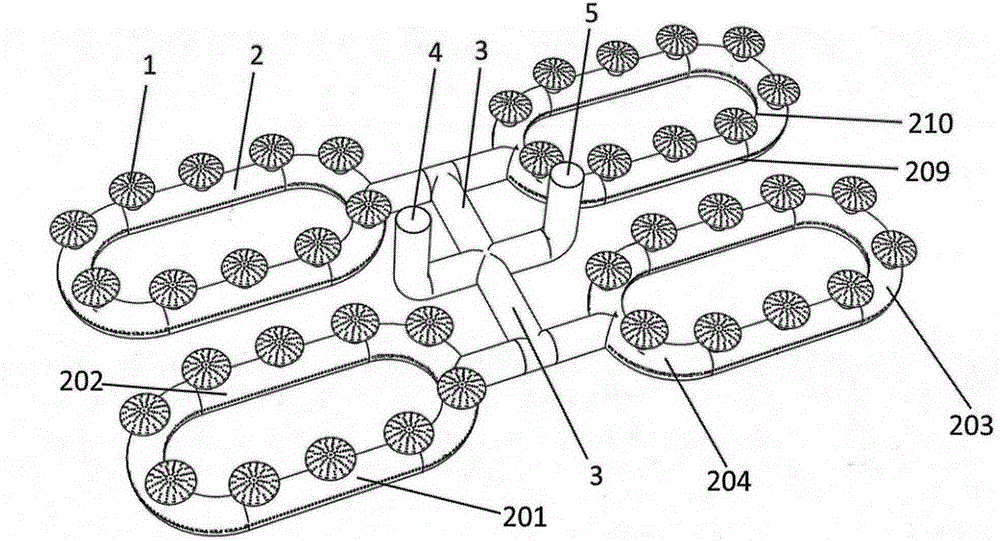

[0024] Please refer to the attached figure 1 , The present invention is an elliptical annular unit aeration system, which is composed of an aerator 1, an elliptical annular pipe 2, a connecting pipe 3, a water inlet pipe 4 and an air inlet pipe 5. Wherein, the aerator 1 is fixed on the elliptical annular pipe 2 by screw connection; the connecting pipe 3 is connected with four elliptical annular pipes 2, the water inlet pipe 4, and the air inlet pipe 5 to form a unit body, The width of the unit body is 1.5-3m, and the length is 3-6m.

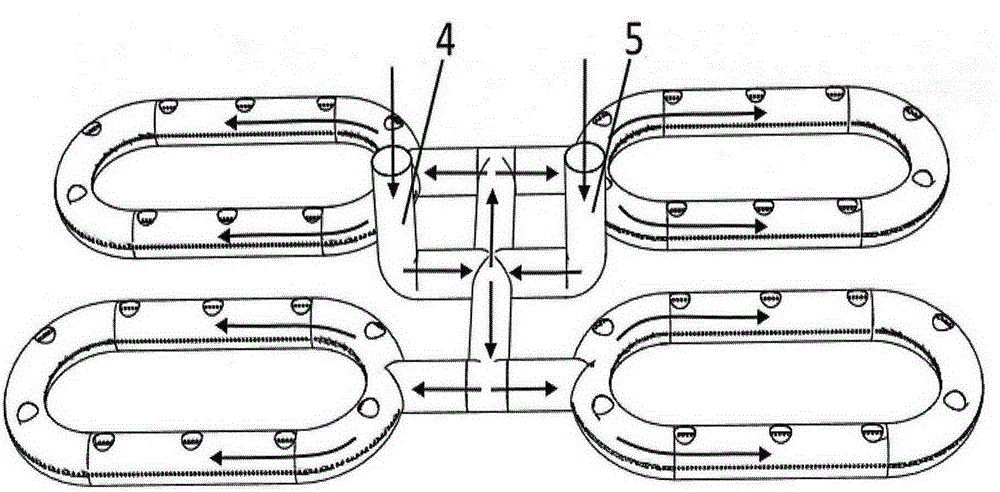

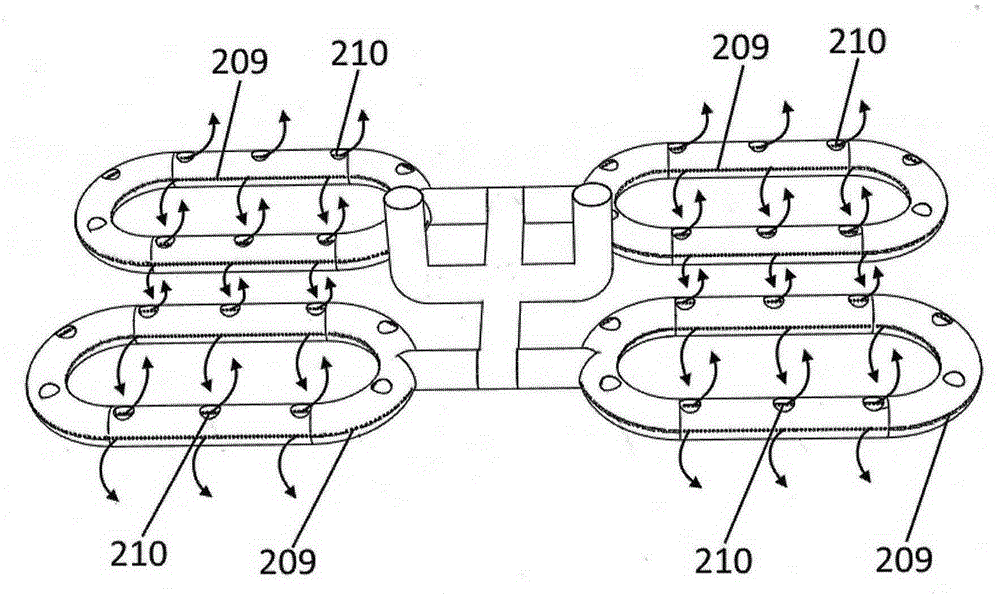

[0025] refer to figure 2 , image 3 with Figure 4 , when the water inlet pipe 4 is closed and the air inlet pipe 5 is in the air intake state, the gas is evenly distributed to the four elliptical annular pipes 2 through the connecting pipe 3 . The elliptical annular pipe 2 is spliced by a left hollow straight pipe 201, a right hollow straight pipe 202, a hollow semicircular arc pipe 203 and a U-shaped tee 204, and the U-shaped tee 204 Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com