Pallet-free bar-forming conveying device for biscuits

A technology for conveying equipment and biscuits, which is applied in the directions of packaging biscuits and food packaging, can solve the problems of high equipment input cost and maintenance cost, affecting production efficiency and high production cost, and achieves a simple structure, high work efficiency, smooth and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

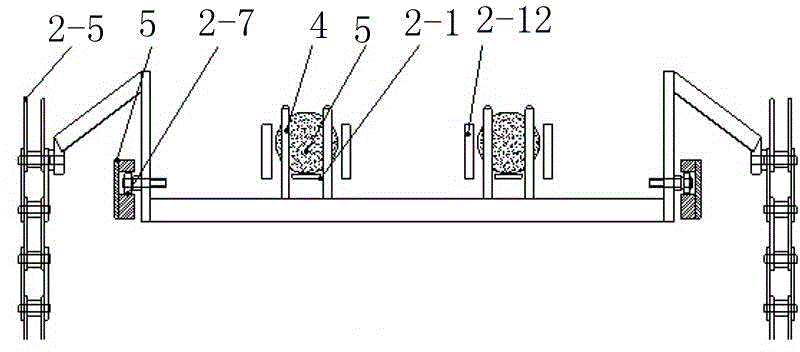

[0033] Such as Figure 1-Figure 14 As shown, the present invention is a kind of unsupported conveying equipment for biscuits, which includes a frame 1 and a biscuit sorting mechanism 2 and a feeding conveying mechanism 3 sequentially arranged on the frame 1; Mechanism 2 includes biscuit support rail 2-1, motor 2-2, transmission mechanism 2-3, cam link transmission mechanism 2-4, left and right biscuit delivery chains 2-5 respectively arranged on both sides of biscuit support rail 2-1 , the shift fork 2-6 installed on the left and right cake chains 2-5, the bearing 2-7 arranged on the two arms of the shift fork, the shift fork track 12-8 and the shift fork slidingly matched with the bearing of the shift fork Fork track two 2-9, shift fork track one 2-8 and shift fork track two 2-9 are established on the guide rail plate 5, and shift fork track two is positioned at the below of shift fork track one, and its two ends are connected with shift fork respectively The first track is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com